BARRING

ASSEMBLY:

To avoid needle

crow!

while needle

is

in

material,

barring

shaft assembly must be

positioned

with

its slide

in

line

with

needle

bar

frame

connection, as

shown

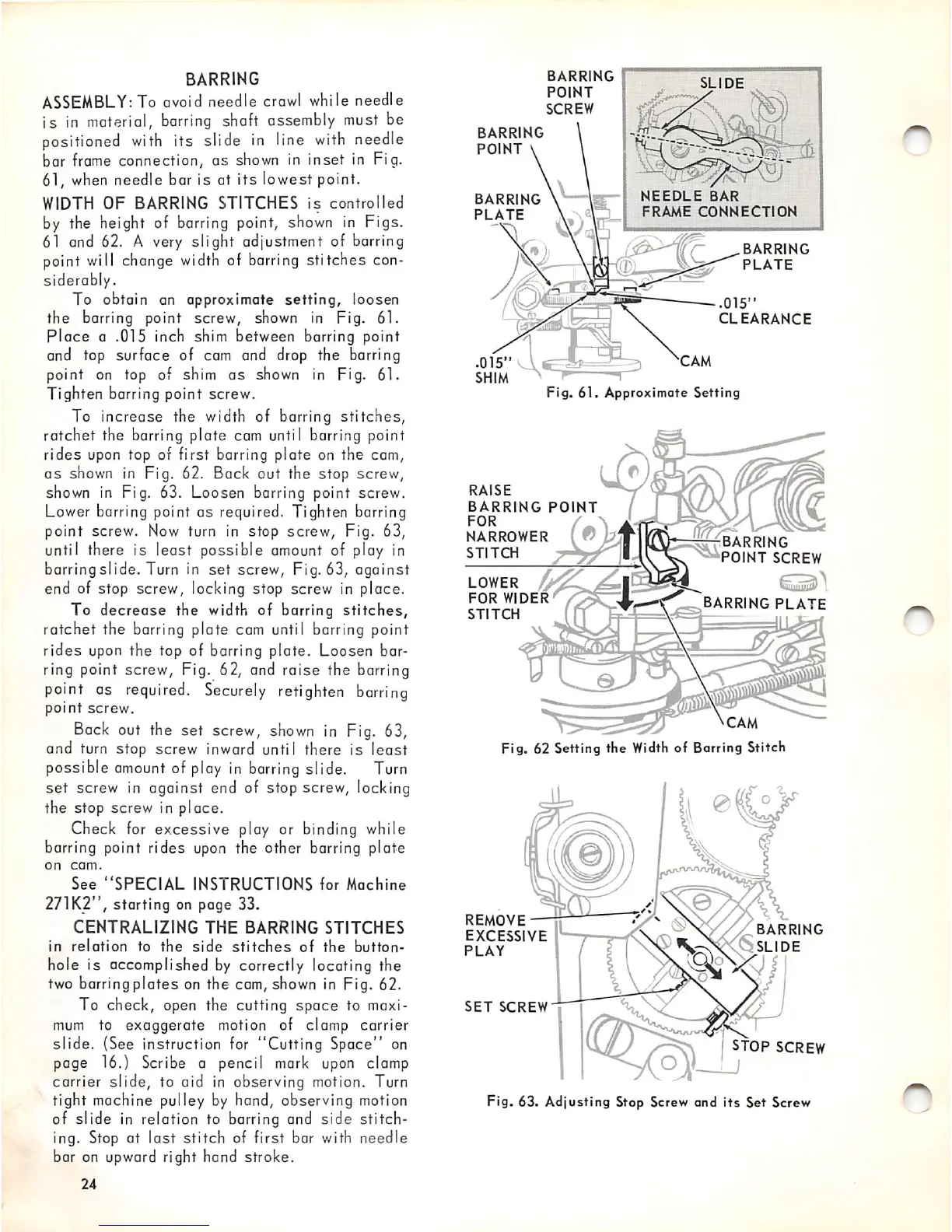

in inset in Fig.

61,

when

needle bar is at

its

lowest point.

WIDTH

OF

BARRING

STITCHES

is

controlled

by the height of

barring

point,

shown

in Figs.

61 and 62. A very slight adjustment of barring

point will change

width

of barring stitches con

siderably.

To obtain an approximate

setting,

loosen

the barring point screw, shown in Fig. 61.

place

a .015 inch shim between barring point

and top surface of cam and drop the barring

point on top of shim

as

shown in Fig. 61.

Tighten barring point screw.

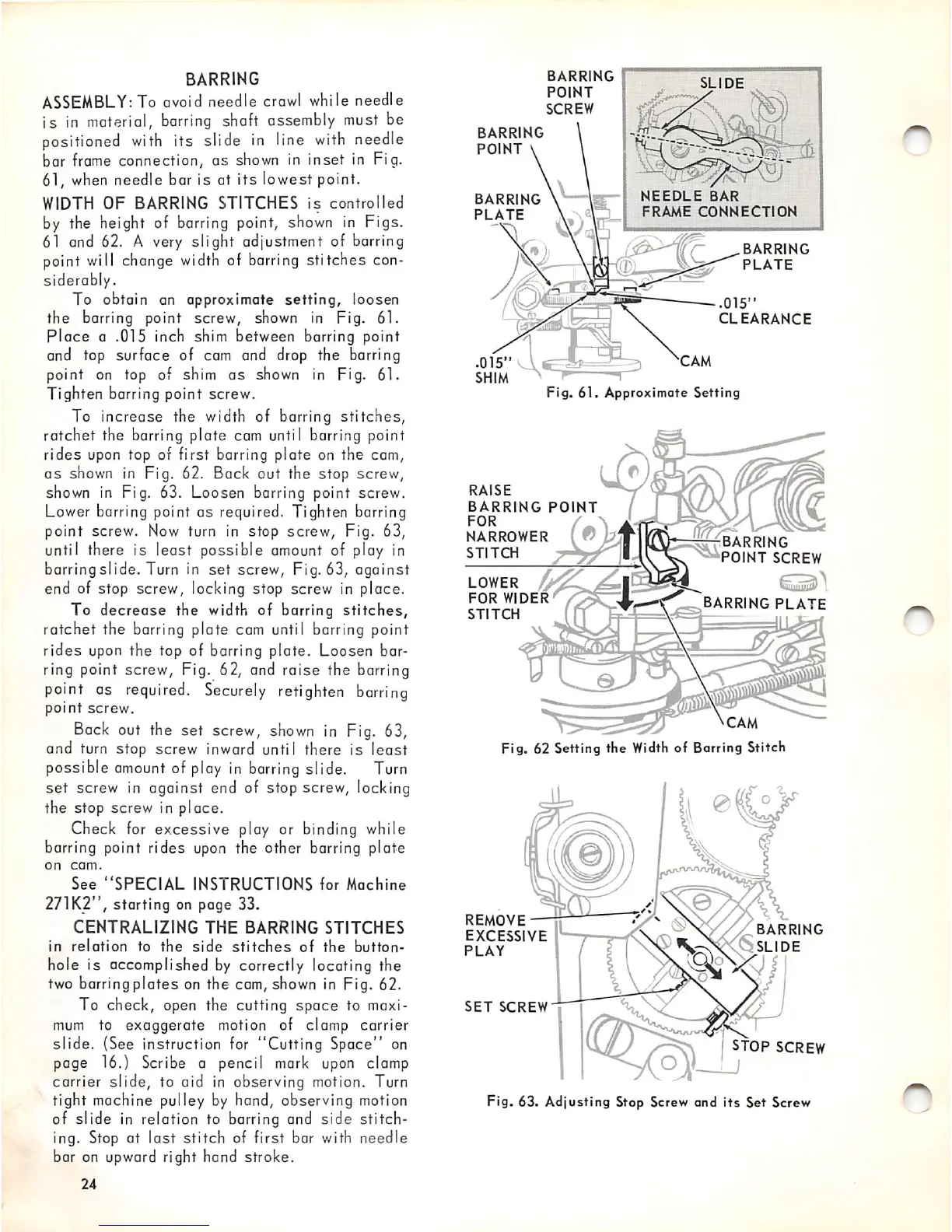

To increase the width of barring

stitches,

ratchet the barring plate cam until barring point

rides upon top of first barring plate on the cam,

as

shown in Fig. 62. Back out the stop screw,

shown in Fig. 63. Loosen barring point screw.

Lower barring point as required. Tighten barring

point screw. Now turn in stop screw. Fig. 63,

until there is least possible amount of play in

barringslide. Turn in

set

screw, Fig. 63, against

end of stop screw, locking stop screw in place.

To

decrease

the width of barring

stitches,

ratchet the barring plate cam until barring point

rides

upon

the top of barring plate. Loosen bar

ring point screw. Fig. 62, and raise the barring

point

as

required.

Securely

retighten

barring

point

screw.

Back

out the set screw,

shown

in Fig. 63,

and turn stop screw inward until there is

least

possible

amount

of

ploy

in

barring

slide.

Turn

set

screw in against end of stop screw, locking

the stop screw in place.

Check for

excessive

play or binding while

barring point rides

upon

the other barring plate

on

com.

See

"SPECIAL

INSTRUCTIONS

for

Machine

271K2", starting on page 33,

CENTRALIZING

THE

BARRING

STITCHES

in

relation

to

the

side

stitches

of

the

button

hole is accomplished

by

correctly locating the

two barring

plates

on the cam, shown in Fig. 62.

To check, open the cutting

space

to maxi

mum

to exaggerate motion of clamp carrier

slide. (See instruction

for

"Cutting Space" on

page 16.) Scribe a pencil

mark

upon

clamp

carrier slide, to aid in observing motion. Turn

tight machine pulley by hand, observing motion

of

slide

in relation to barring and

side

stitch

ing. Stop at

last

stitch

of first bar with needle

bar on upward right hand stroke.

24

BARRING

POINT

SCREW

BARRING

POINT

BARRING

PLATE

SLIDE

\ V - V

VA'

- - C

NEEDLE

BAR

FRAME

CONNECTION

BARRING

PLATE

.015"

CLEARANCE

.015"

SHIM

Fig.

61.

Approximate

Setting

RAISE

BARRING

POINT

FOR

NARROWER

STITCH

LOWER

FOR

WIDER

STITCH

BARRING

POINT

SCREW

BARRING

PLATE

Fig. 62 Setting the

Width

of Barring Stitch

REMOVE

EXCESSIVE

PLAY

SET

SCREW

BARRING

§

SLIDE

STOP SCREW

Fig. 63. Adjusting Stop Screvr and

its

Set Screw

r^

Loading...

Loading...