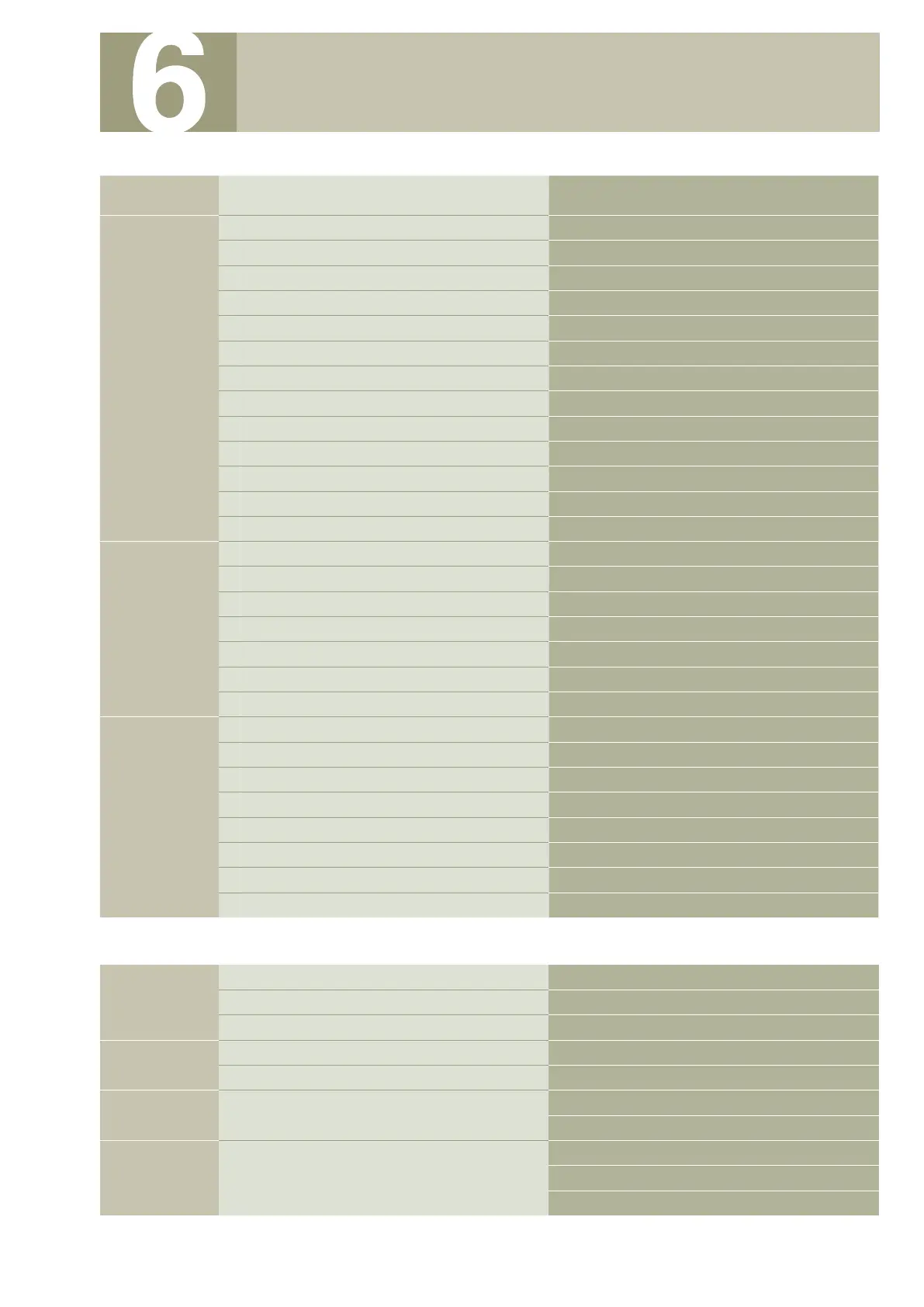

Troubleshooting

Problems Possible Causes Possible Solutions

Loosen stitches

1.

Wrong threading

1.

Rethread the machine correctly

2.

Thread is thicker than needle hole

2.

Use proper needle for fabric and thread

3.

Inadequate thread tension

3.

Readjust the thread tension unit

4.

Needle thread is not lubricated

4.

Fill in the silicon oil

5.

Wrong setting of needle and loopers

5.

Readjust needle and loopers

Uneven stitches

1.

Wrong threading

1.

Rethread the machine correctly

2.

Thread stand installed wrong

2.

Install thread stand correctly

3.

Lower knife installed wrong

3.

Install lower knife correctly

4.

Knives do not trim neatly

4.

Readjust knife and/or sharpen or replace it

5.

Thread disc or guide is burred

5.

Grind off, polish or replace by a new part

6.

Needle point is damaged

6.

Change the needle

7.

Inadequate height of feed dog

7.

Readjust the feed dogs

8.

Inadequate thread tension

8.

Readjust the thread tension unit

Wrinkled stitches

1.

Thread tension is too strong

1.

Readjust the thread tension unit

2.

Inadequate pressure of presser foot

2.

Readjust presser foot pressure

3.

Inadequate height of feed dog

3.

Readjust the feed dogs

4.

Knives do not trim neatly

4.

Readjust knife and/or sharpen or replace it

5.

Differential feed is not matched

5.

Readjust differential feed ratio

6.

Needle is too thick

6.

Use proper needle for fabric and thread

7.

Seam width is too narrow against the chain-off finger

7.

Readjust seam width or replace chain-off finger

Thread chain

does not come

out smoothly

1.

Presser foot installed wrong

1.

Reinstall presser foot correctly

2.

Inadequate timing of looper thread cam

2.

Readjust looper thread cam

3.

Double chain looper installed wrong

3.

Reinstall double chain looper correctly

4.

Wrong threading

4.

Rethread the machine correctly

5.

Inadequate thread tension

5.

Readjust the thread tension unit

6.

Wrong relation between needle and looper

6.

Readjust needle and looper

7.

Needle plate, thread disc or presser foot ar burred

7.

Grind off, polish or replace by a new part

8.

Thread tension disc is rough

8.

Polish thread tension disc

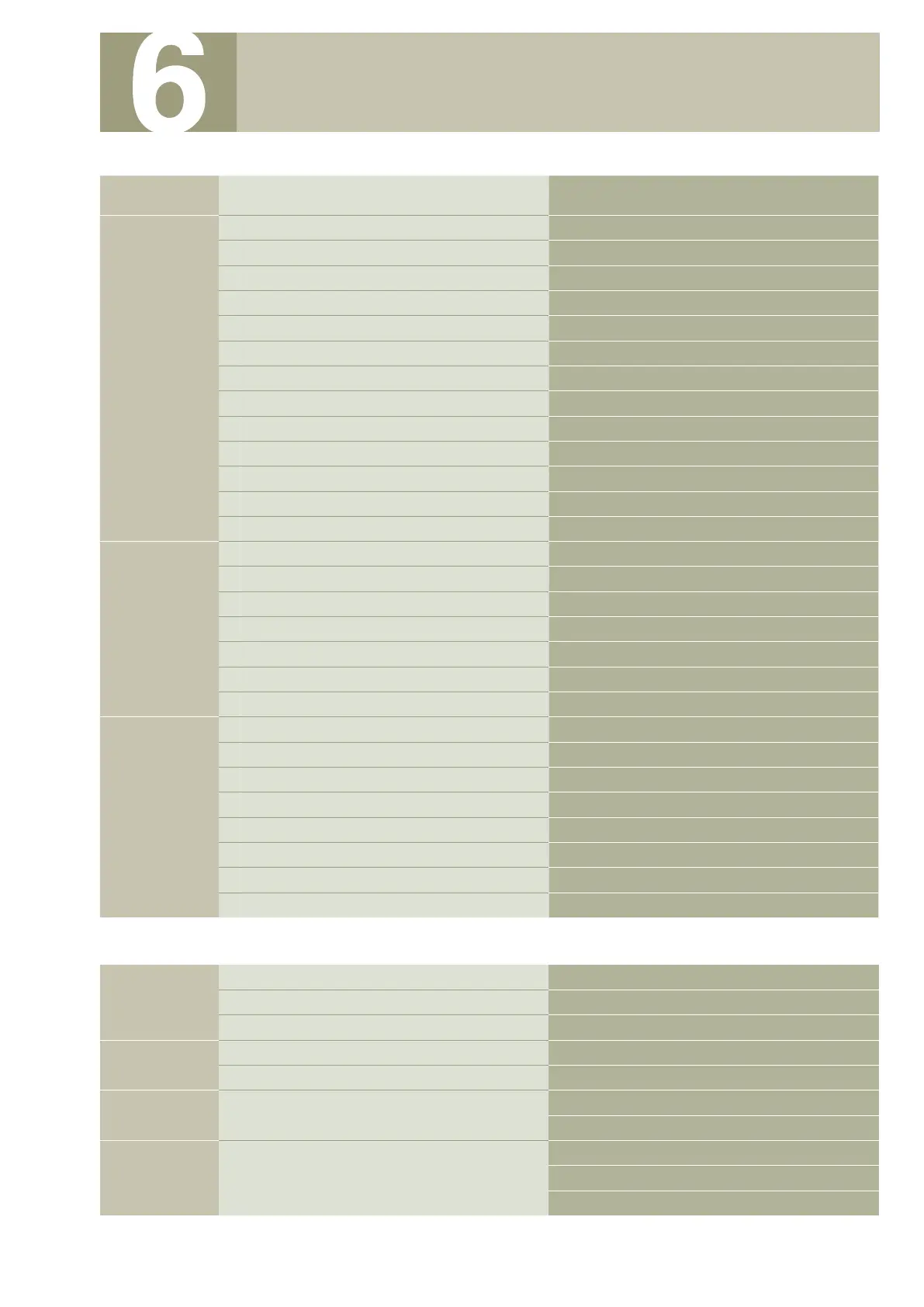

The motor has not operated properly.

1.

Sewing material is too heavy.

1.

Change to a lightweight material.

2.

The machine needs lubrication.

2.

Applying lubrication oil.

The motor has over-current or under-voltage

1.

The motor power supply is not a proper voltage.

1.

Check the voltage of the motor

The motor has not function

1.

Main switch 'Off' and 'On' again

1.

Check the motor connector and wire condition.

2. Replace new ES DD motor

E1

E2

2.

Replug the motor connector.

3.

Replace new ES DD motor.

E3

E4

The signal of the motor hall is wrong

For control system.

High Speed Flat Bed Interlock Sewing Machine | Instruction Manual and Parts List

19

Loading...

Loading...