Page22 of 22

Date: 12.08.2020

1: Speed log performance may be eected by growth, shell, etc on sensor head.

Sensors may need carefully cleaned for growth to regain performance.

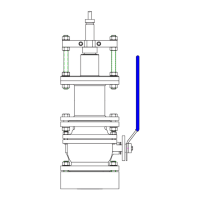

2: Sea valves consist of moving mechanical parts.

Greasing of mechanical parts may be considered to ensure operation and avoid corrosion.

Sea valves installed in wet areas (ballast tank etc) should be regularly inspected and greased.

3: Dry docking.

Gaskets and o-rings may be considered to be replaced during dry docking period.

Inspection of sea valve operation should be considered before a dry docking period to have any spare parts

available at dry docking.

4: O-rings are included with sensors and should be replaced when/if sensor is replaced.

Maintenance Tasks for inactive sensors

(If the system is to be o / and the vessel static for over 6 months (cold water), 3 months warm water).

When closing the vessel.

• Turn o unit at power, both Display and transceiver.

• Mark the alignment of the sensor on the gate valve and sensor ange/pole.

• Lift the sensor into the gate valve and close the valve.

• Grease the valves external moving parts

When restarting

• Heat the areas containing display, to allow condensation to evaporate.

• Lift and inspect the sensor head (or send diver). Carefully clean away growth.

• Redeploy the sensor taking care with alignment.

• Start the system.

• On rst test, check alignment (Head Err in the calibration screen).

Dry docking in temperatures below freezing point

If vessel is to be dry docked in temperatures below freezing point water remained inside sea valve may cause

damage to sea valve or sensor/transducer.

13. MAINTENANCE

SKIPPER Electronics AS

SB-100-XX Operation and Installation Manual

Loading...

Loading...