Chapter 7 – Prestart Inspection

A46JRT – 0260996 35

• If the power was off, push the reset button to

restore power.

• If the power was on, repair or replace the recep-

tacle.

Level Sensor

Use the following procedure to test the level sensor:

Danger

The aerial platform can tip over if it becomes unsta-

ble. Death or serious injury will result from a tip-over

accident. Do not drive an elevated aerial platform on

soft, uneven, or sloping surfaces. Do not drive the

machine on grades that exceed 25 percent.

1. With the machine in the stowed position, drive on

a grade that is between 5 and 10 degrees. Stop to

ensure the brakes engage.

2. Extend the tip boom about 2′ (60 cm).

3. Verify that the tilt alarm sounds and the tilt warning light

on the lower and upper control panels are illuminated.

Warning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury could result from such accidents. Do not alter,

disable, or override any safety device.

4. If the alarm does not sound and the warning lights

do not illuminate, remove the machine from service

until the problem is corrected.

5. Retract the tip boom and drive the machine to a

smooth, flat, level surface.

Drive Motion Alarm

The machine is equipped with a drive motion alarm.

• Operate the machine functions to ensure that the

alarm sounds to warn personnel in the area that the

aerial platform is in motion.

All Motion Alarm

The machine may be equipped with an all motion alarm.

• Operate machine functions to ensure that the alarm

sounds to warn personnel in the area that the aerial

platform is in motion.

Sandblast Protection Kit

The optional sandblast protection kit protects the cylinders

from abrasion while sandblasting or from paint overspray.

Rubber covers protect each cylinder rod as it extends

and retracts. The covers prevent sand and paint from

damaging the cylinder seals and rod.

Electrical Power Outlet

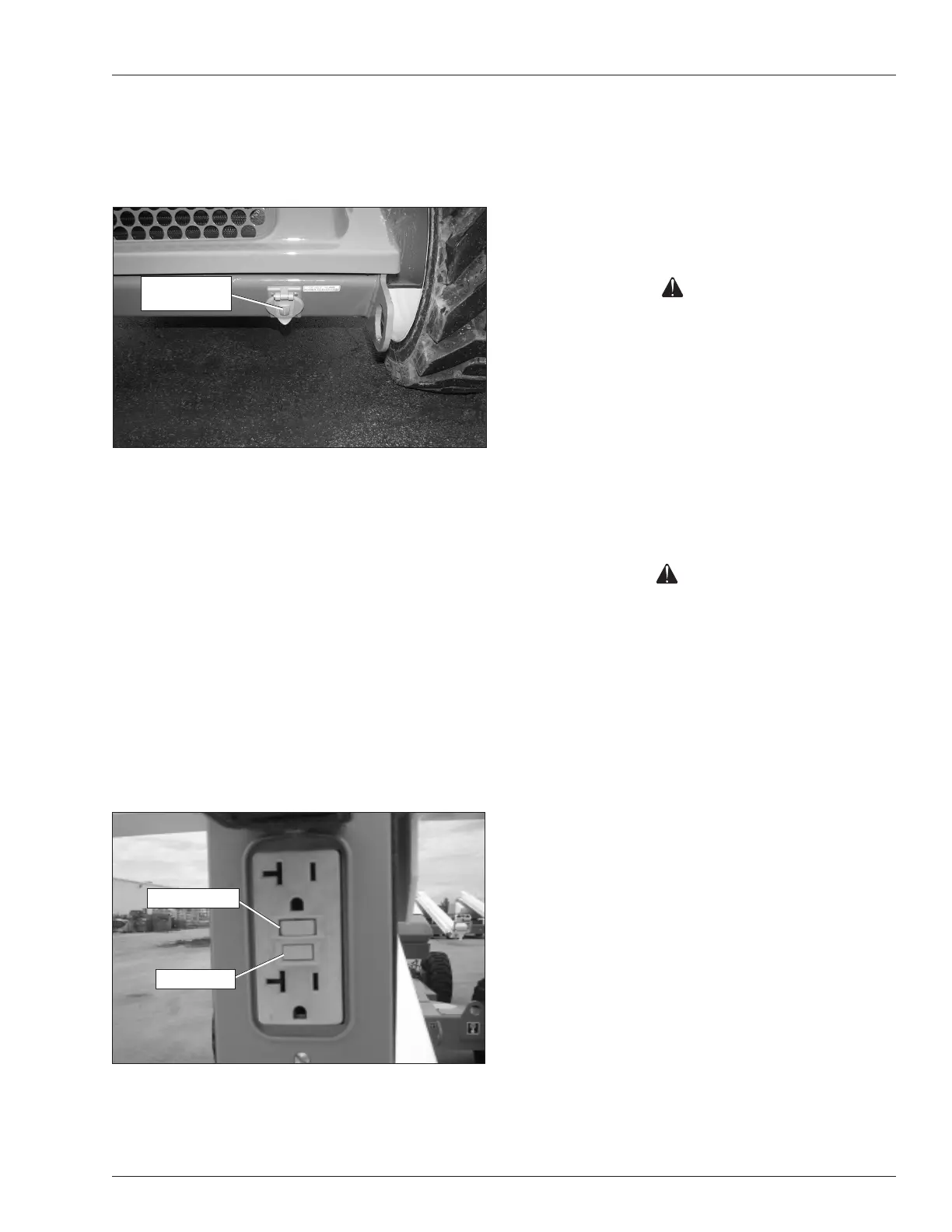

Connect a source of 110 volt AC power to the power-in-

put connector on the right side of the chassis (refer to

Figure 7.15).

Figure 7.15 – Power-Input Connector

Some machines may have an electrical outlet at the

platform, but no power-input connector on the chassis. In

that case, power is supplied by an optional AC generator.

An external power source is not required.

With the engine running, place the AC generator switch

in the generator position to provide electrical power to the

electrical outlet at the platform and to the outlet on the

end of the generator housing.

Plug an electrical tool into the receptacle at the platform

and at the generator and try to operate the tool to verify

proper operation of the outlet.

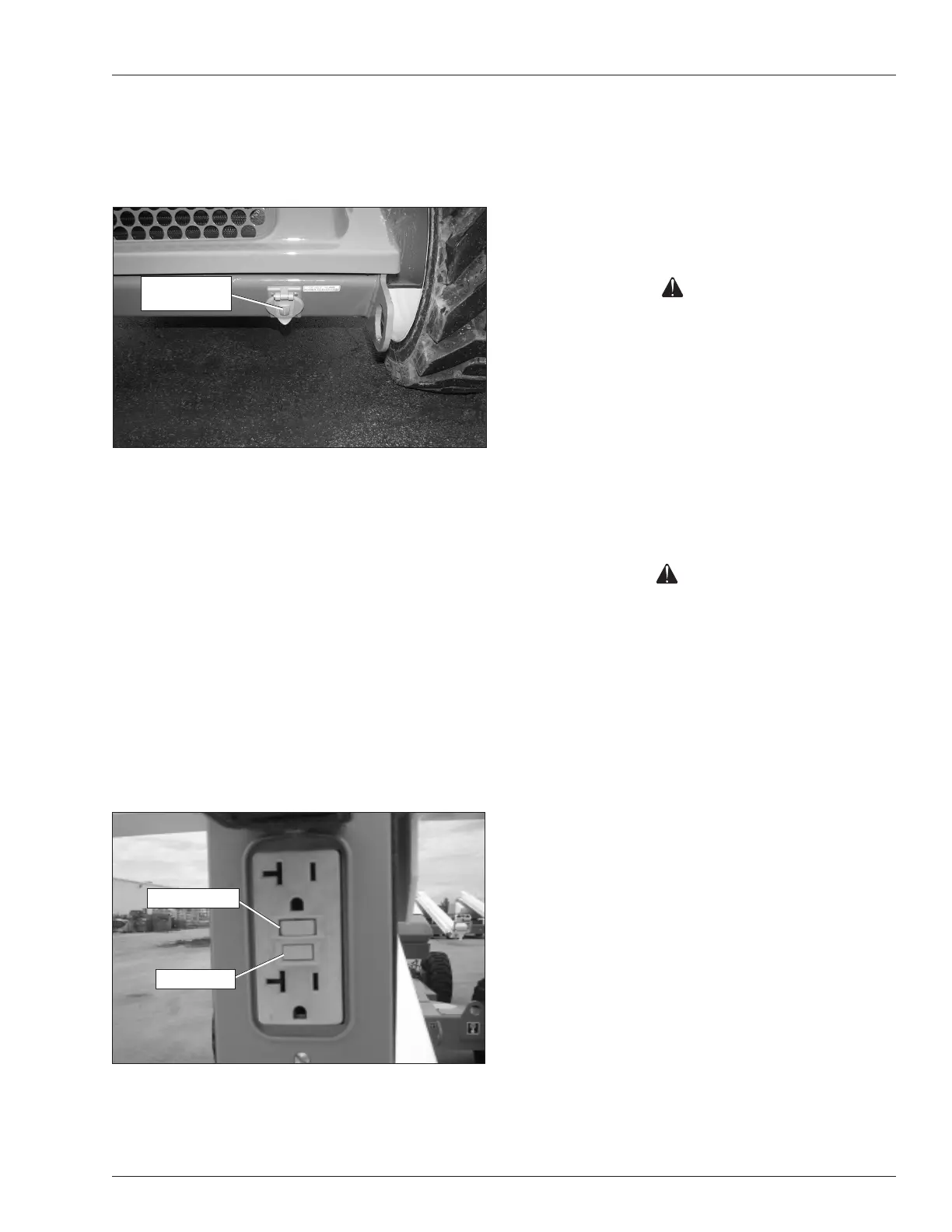

The outlet is equipped with a ground fault circuit interrupter

(GFCI). Use the following procedure to test the GFCI.

1. Push the test button (refer to Figure 7.16).

Figure 7.16 – Electrical Power Outlet

2. Plug an electrical tool into the outlet and verify the

power is off.

Power-Input

Connector

Test Button

Reset Button

Loading...

Loading...