Chapter 8 – Prestart Inspection

S1930E/S1932E/S2632E – 1360460 25

Caution

Not all hydraulic uid is suitable to use in the hy-

draulic system. Some have poor lubricating char-

acteristics and may increase component wear. Only

use hydraulic uid as recommended.

3. If necessary, add uid of the proper type.

Note

Refer to Chapter 2 for the proper type and grade of

hydraulic uid to use. The need to regularly add uid

indicates a leak that should be corrected.

4. Replace the cap making sure it is tightly in place.

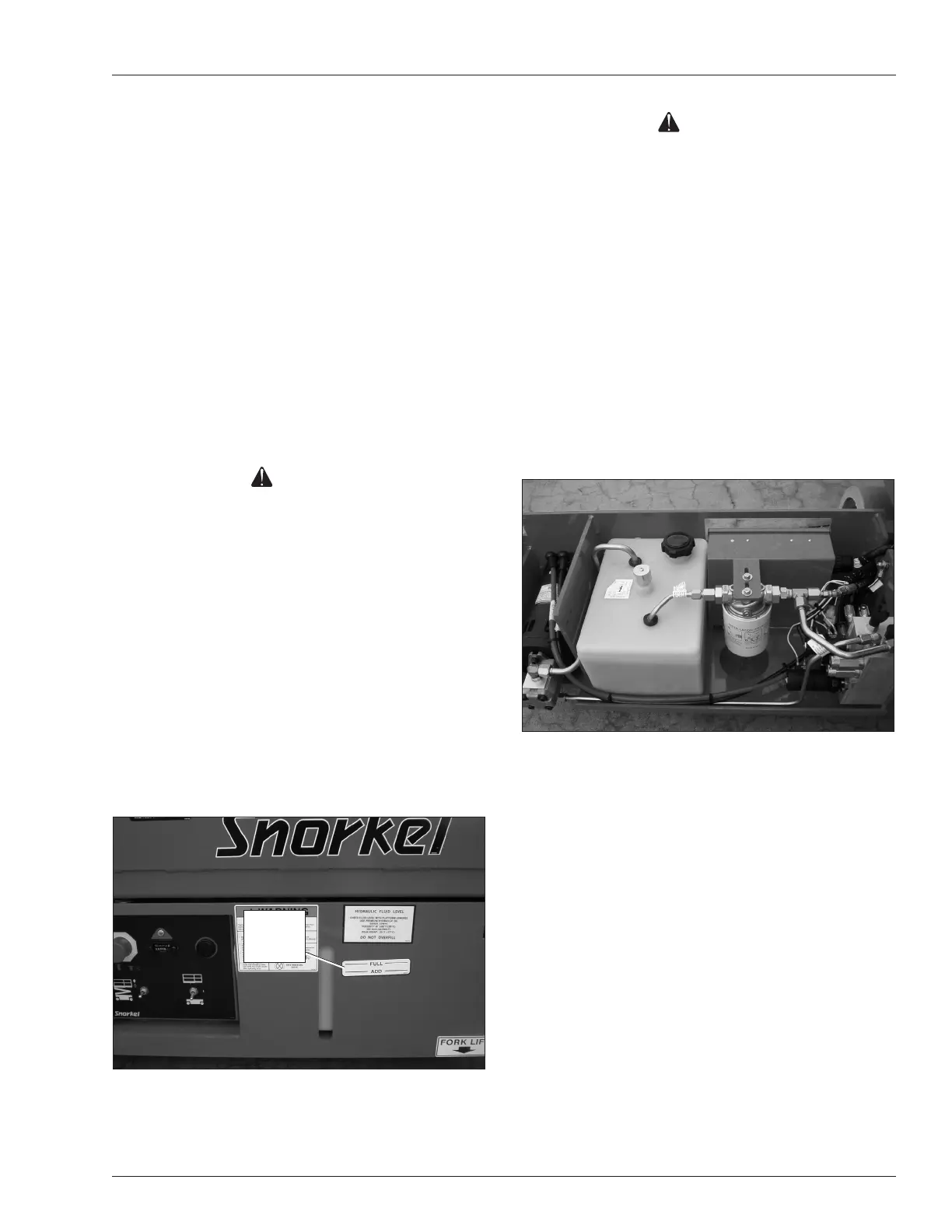

Hoses, Tubes, and Fittings

To inspect the hoses, tubes and ttings:

1. Inspect all hydraulic hoses, tubes, and ttings for

wear, leakage, or damage (refer to Figure 8.7).

Figure 8.7 – Hoses, Tubes, and Fittings

2. Make sure the hoses are properly routed to avoid

sharp edges, kinking, and scufng.

3. Inspect the tubes for dents or other damage that may

restrict uid ow.

4. Make sure all hoses and tubes are held rmly in their

support brackets.

5. Check under the chassis for uid that has leaked. Hy-

draulic uid leaks are easily visible on the ground.

Free-Wheeling Valve

The free-wheeling valve is located on the hydraulic mani-

fold in the hydraulic tray. Check the free-wheeling valve

to make sure it is fully closed (clockwise).

3. Using the lower controls completely lower the plat-

form.

Cables and Wiring Harness

To inspect the cables and wiring harness:

1. Visually inspect all cables and wiring for wear and/or

physical damage such as loose connections, broken

wires, and frayed insulation.

2. Check the wiring in areas where a change in routing

direction may cause them to become pinched.

3. Make sure the cables and wires are properly routed

to avoid sharp edges, pinching, and scufng.

Hydraulic System

Hydraulic power is supplied from a single stage hydraulic

pump with a 4.25 horsepower DC electric motor.

Danger

Hydraulic uid escaping under pressure can have

enough force to inject uid into the esh. Serious

infection or reaction will result if medical treatment is

not given immediately. In case of injury by escaping

hydraulic uid, seek medical attention at once.

The hydraulic reservoir, pump, lter, and control valve

are located in the hydraulic tray on the right side of the

chassis.

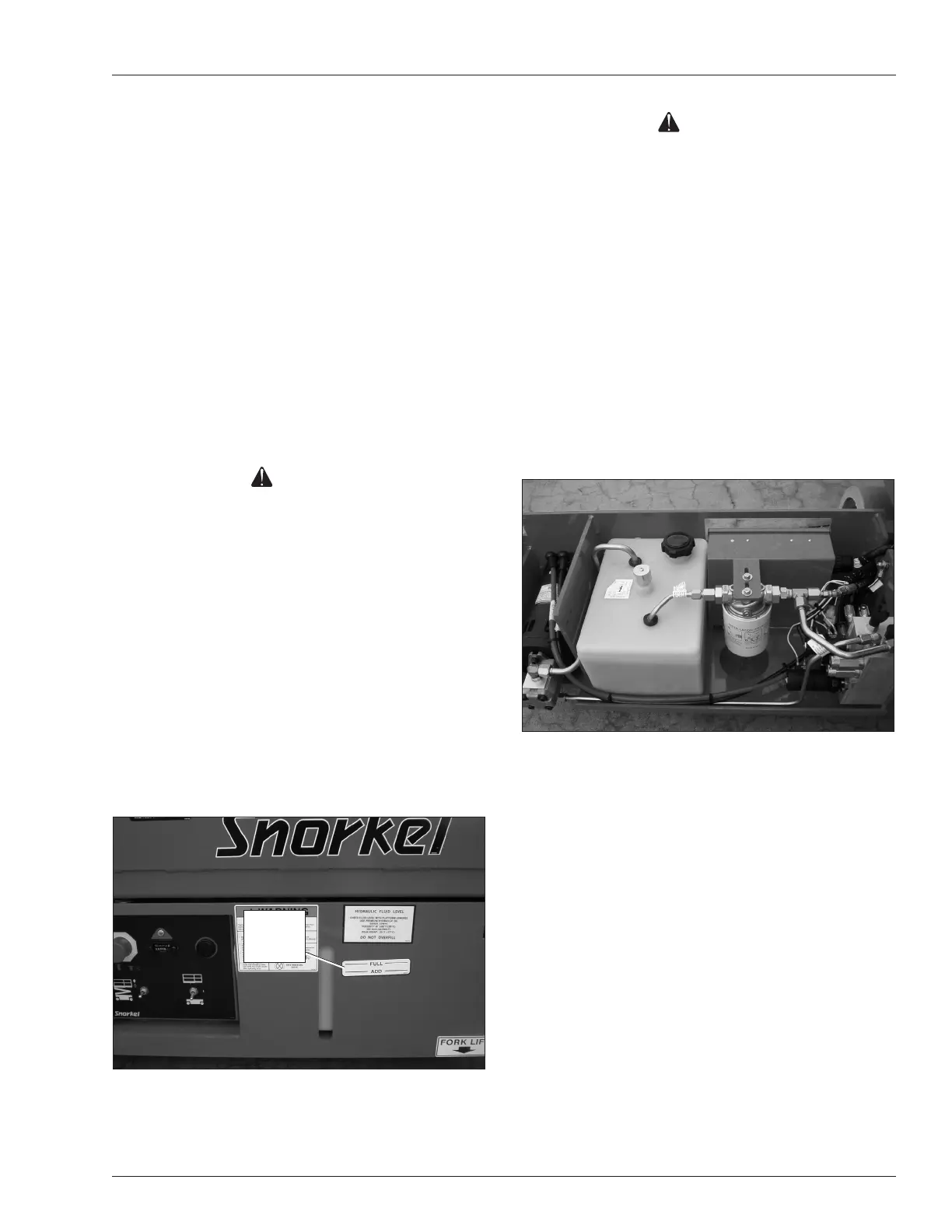

Fluid Level

To inspect the uid level:

1. Make sure the aerial platform is fully stowed on a

level surface.

2. The uid level must be between the add and full

marks (refer to Figure 8.6).

Figure 8.6 – Hydraulic Tray

Fluid

Level

Indicator

Loading...

Loading...