S1930E/S1932E/S2632E – 1360460 49

Chapter 12 – Troubleshooting

The troubleshooting chart may be used to locate and

eliminate situations where machine operation may be

interrupted. If the problem cannot be corrected with the

action listed, stow the machine and remove it from ser-

vice. Repairs must be made by qualied maintenance

personnel.

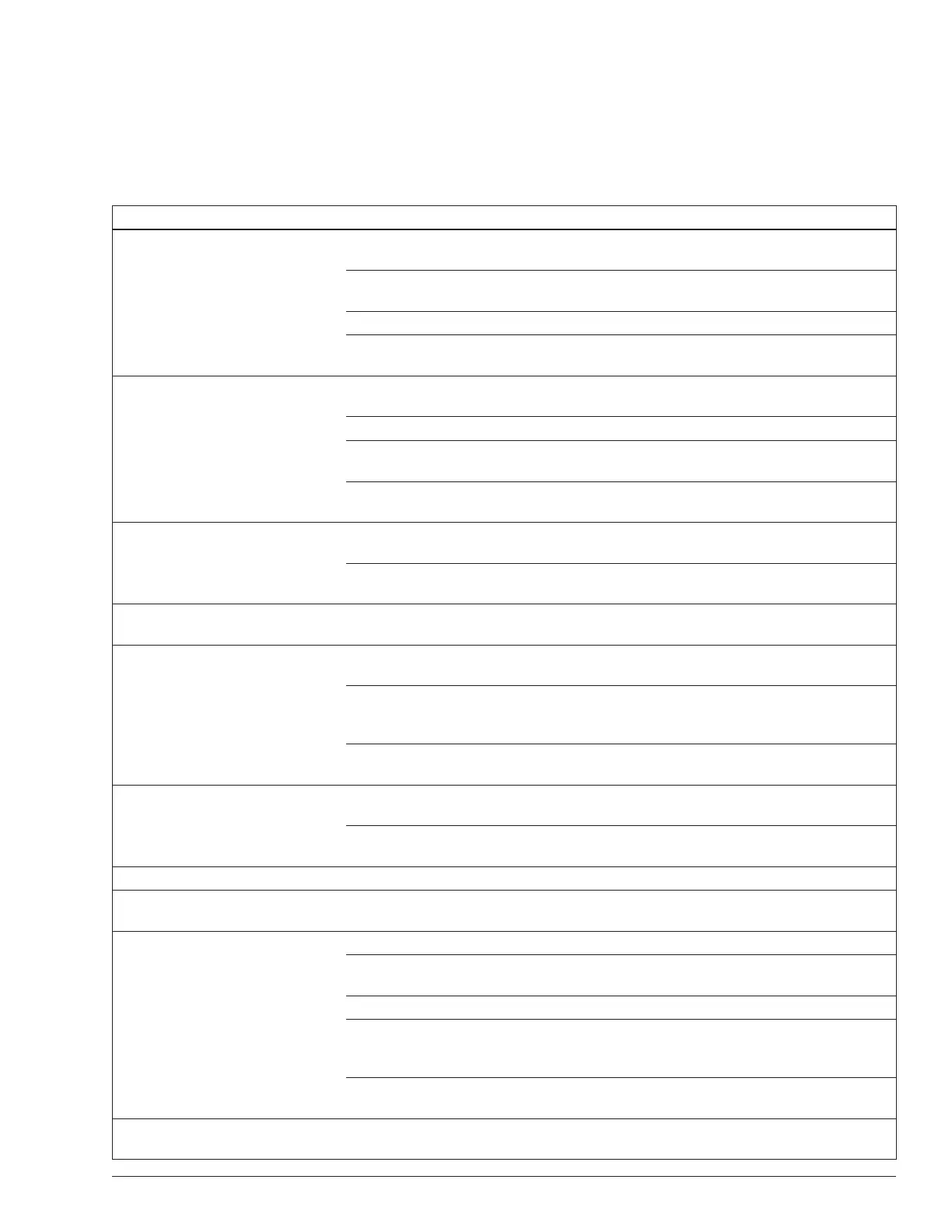

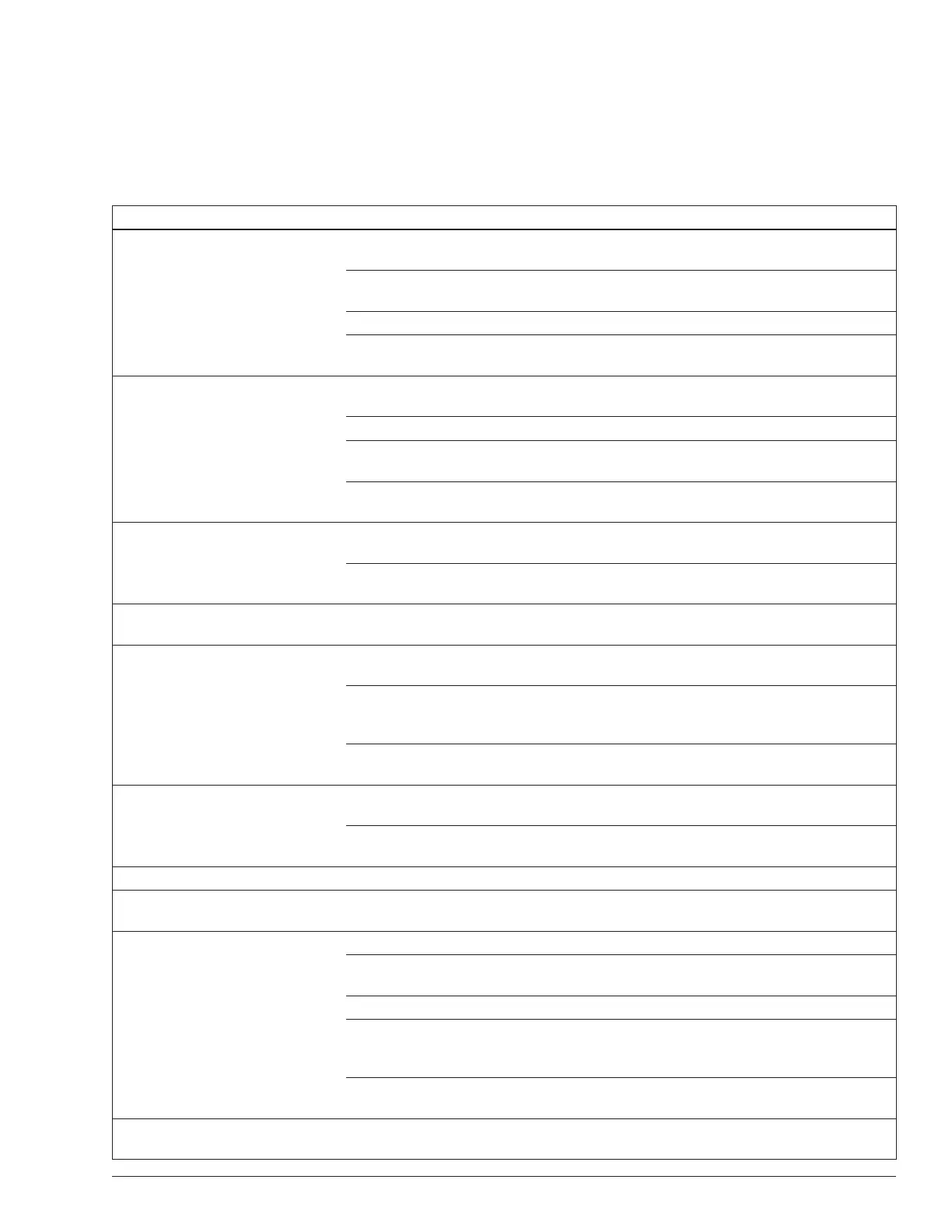

Troubleshooting Chart

Symptom Possible Cause Corrective Action

All functions stop working. Motor or pump failure. Manually stow the machine using the

emergency lowering knob.

Low uid level in reservoir. Check hydraulic uid level. Add correct

type of uid if necessary.

Batteries discharged. Recharge batteries.

Electrical system malfunction. Stow the machine and do not operate until

repairs are made.

Platform will not raise or lower

from lower controls.

Control selector switch is in the upper

control position.

Place the switch in the lower control

position.

Battery disconnect is turned off. Place the switch in the on position.

Emergency stop button is pushed

inward to the off position.

Pull the emergency stop button outward

to the on position.

Emergency lowering lever is not prop-

erly disengaged.

Make sure the lever returns to the normal

operating position.

Platform will not raise or lower

from upper controls.

Drive/lift selector is in the drive posi-

tion.

Place switch in the lift position.

Emergency lowering lever not prop-

erly disengaged.

Make sure the lever returns to the normal

operating position.

Platform will not raise and alarm

is sounding.

Machine is not on a level surface. Lower the platform and drive to a level

surface.

Platform will not raise, or raises

slower than normal.

Emergency lowering lever/handle not

properly disengaged.

Make sure the lever/handle returns to the

normal operating position.

Platform capacity has been ex-

ceeded.

Remove load from platform. Refer to

platform capacity placard for maximum

capacity.

Low battery charge. Check the battery charge indicator and

recharge the batteries if necessary.

Platform drifts down. Emergency lowering lever not prop-

erly disengaged.

Make sure the lever returns to the normal

operating position.

Hydraulic system malfunction. Stow the machine and do not operate until

repairs are made.

Platform will not lower. Safety prop in place. Stow the safety prop.

Platform will not extend. Latch pin still in place. Remove the latch pin before extending

the platform.

Drive functions don’t work.

Drive/lift selector is in the lift position.

Place the switch in the drive position.

Machine is not on a level surface or

too steep a grade.

Lower the platform and drive to a level

surface.

Free-wheeling valve is open. Fully close the free-wheeling valve.

Load capacity exceeded. Remove load from platform. Refer to

platform capacity placard for maximum

capacity.

Low hydraulic system pressure. Stow the machine and do not operate until

repairs are made.

Machine will not climb a 25 per-

cent grade – S2632E only.

Drive range selector is not in the low

(turtle) position.

Place the switch in the low (turtle) posi-

tion.

Loading...

Loading...