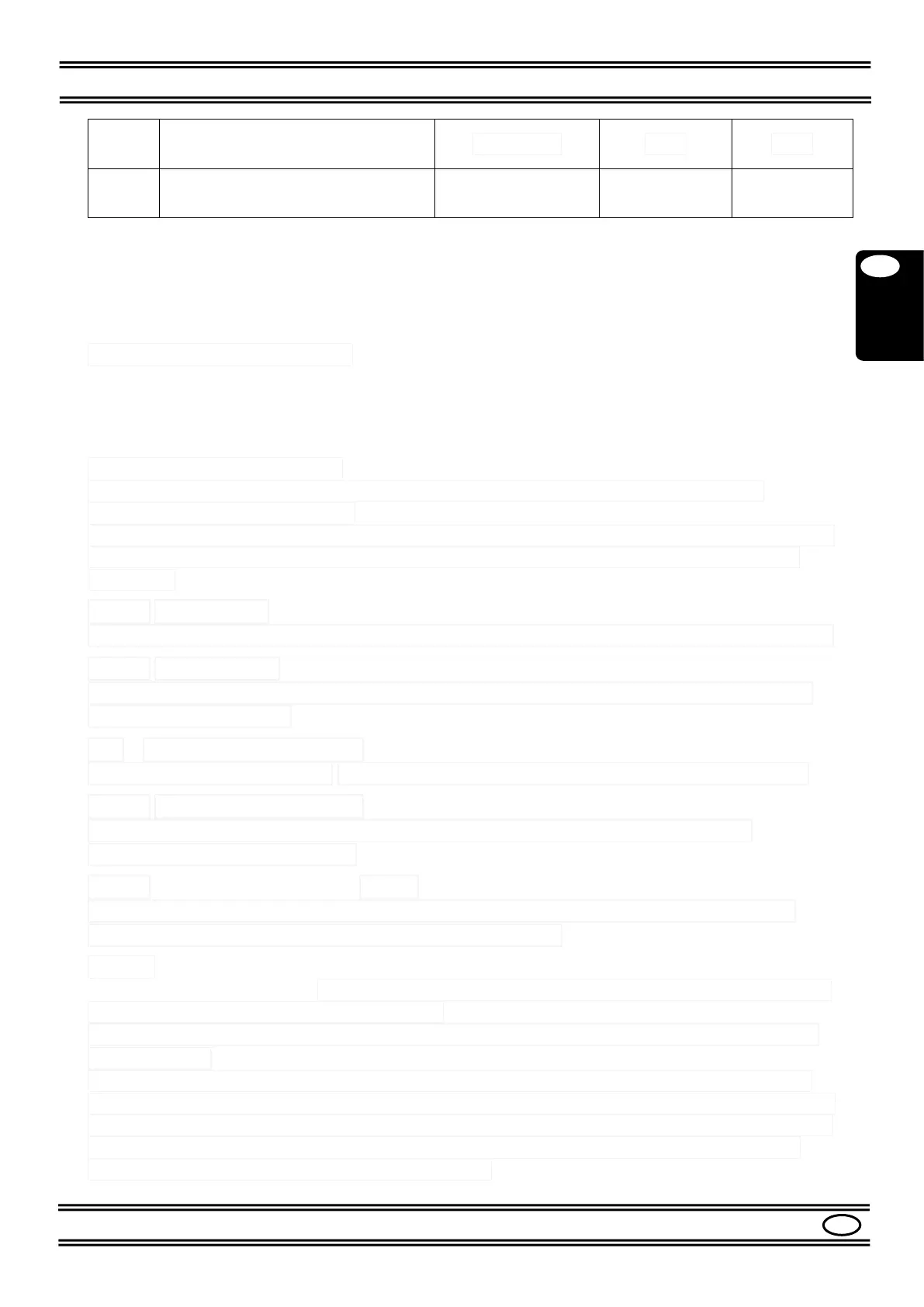

Table 4: SUBMENU parameters

(- - -) = parameter not available in this machine

Below is the detailed description of the parameters of Table 4.

P01 - Burn Back Time (BBT)

Adjust the BBT value so that the length of the wire exiting the socket does not stick to the

workpiece or to the torch.

A high value tends to make the wire stick to the contact tip, a low value tends to make the wire

stick to the workpiece.

P02 - Wire approach speed

It is the wire speed when the machine is in no load. Once the arc is ignited, the speed

automatically goes to the set one.

When the initial feed rate is too high, the wire will tap several times before igniting a stable arc;

if the feed speed is too slow, the initial arc will be too long, and the wire could melt into the

wire guide.

P03 - Pre-gas time

Time too long will cause a waste of time and gas. Time too short may cause triggering craters.

P04 - Post-gas time

Time too long will cause waste of time and gas; time too short may cause craters during the

filling period of the crater.

P05 - Initial period value (in 4-Times Special mode)

Set the variation in percentage between the initial parameters and the welding parameters.

P06 - Final period value (in 4-Times Special mode)

Set the variation in percentage between the final period parameters and the welding

parameters to properly fill craters.

P07 - Transition period value (in 4-Times Special mode)

During the special 4 times mode, set the transition time between the parameters. This will

eliminate the sharp variation between the three parameters.

P11 - Double pulse frequency

Double Pulsation Welding is obtained by modulating, at low frequency, the synergy between

two values called High Pulse and Low Pulse.

It is possible to adjust this frequency from OFF, single level of pulse, to dual-pulsed between

0.5 and 5.0 Hz.

Compared to single pulsed welding, double pulsed offers numerous advantages. The first is

that, without manually oscillating, the weld will automatically take the shape of a "herringbone".

Second, the depth and density of the welding seam will be adjustable with more precision, and

you will obtain optimal control of the heat input. Finally, you will get a colder weld pool with

lesser deformation of the workpiece at low currents.

Loading...

Loading...