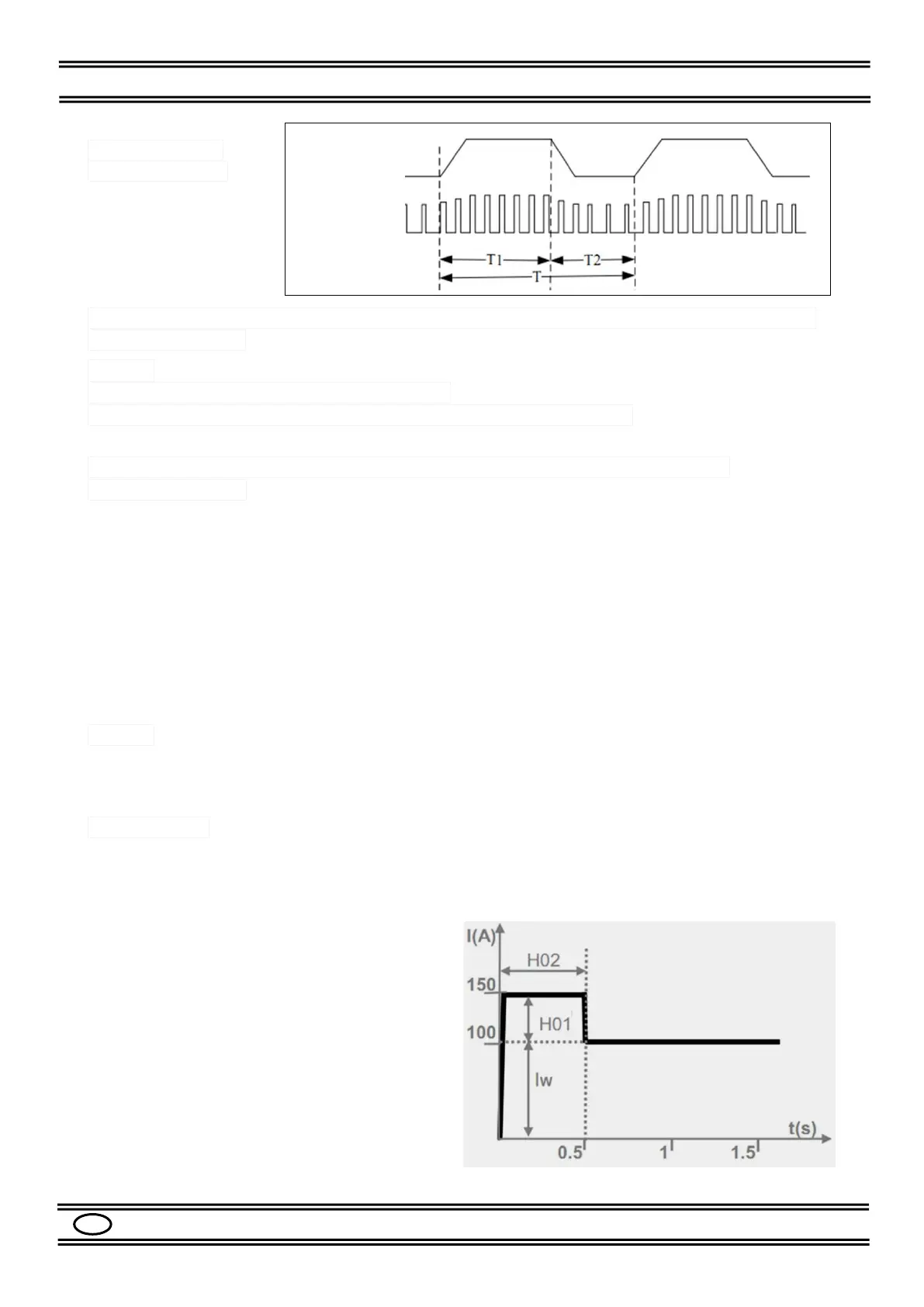

Waveform of the

Double pulsation

Fig. 10

In Fig. 10 "T" indicates the double pulse frequency (P11), "T1" the high pulse value and "T2"

the low pulse value.

P12 - Arc length correction of the high pulse group (in double pulsation)

To adjust the width of the “herringbone” bead.

Set high values for a wider bead and low values for a narrower bead.

P13 - Double pulse speed offset (in double pulsation)

To adjust the depth of the bead. Higher values correspond to greater depth of the

"herringbone" bead.

P14 - High Pulse Group Ratio (in double pulsation)

Set high value for greater proportion of the entire projection and groove of the “herringbone”

bead.

P17 - Initial current time (in 4-Times Special mode)

It is the time in which the initial current P05 remains, after this time the current will reach the

set value. With the OFF setting this function is not active.

P18 - Final current time (in 4-Times Special mode)

It is the time in which the final crater filling current P06 remains, after this time the current will

go to 0. With the OFF setting this function is not active.

P19 - Standard mode selection (not synergic)

OFF = synergic mode;

ON = standard mode, in this mode the two knobs (20) and (21) allow you to adjust the

CURRENT and VOLTAGE values independently (no longer synergistic).

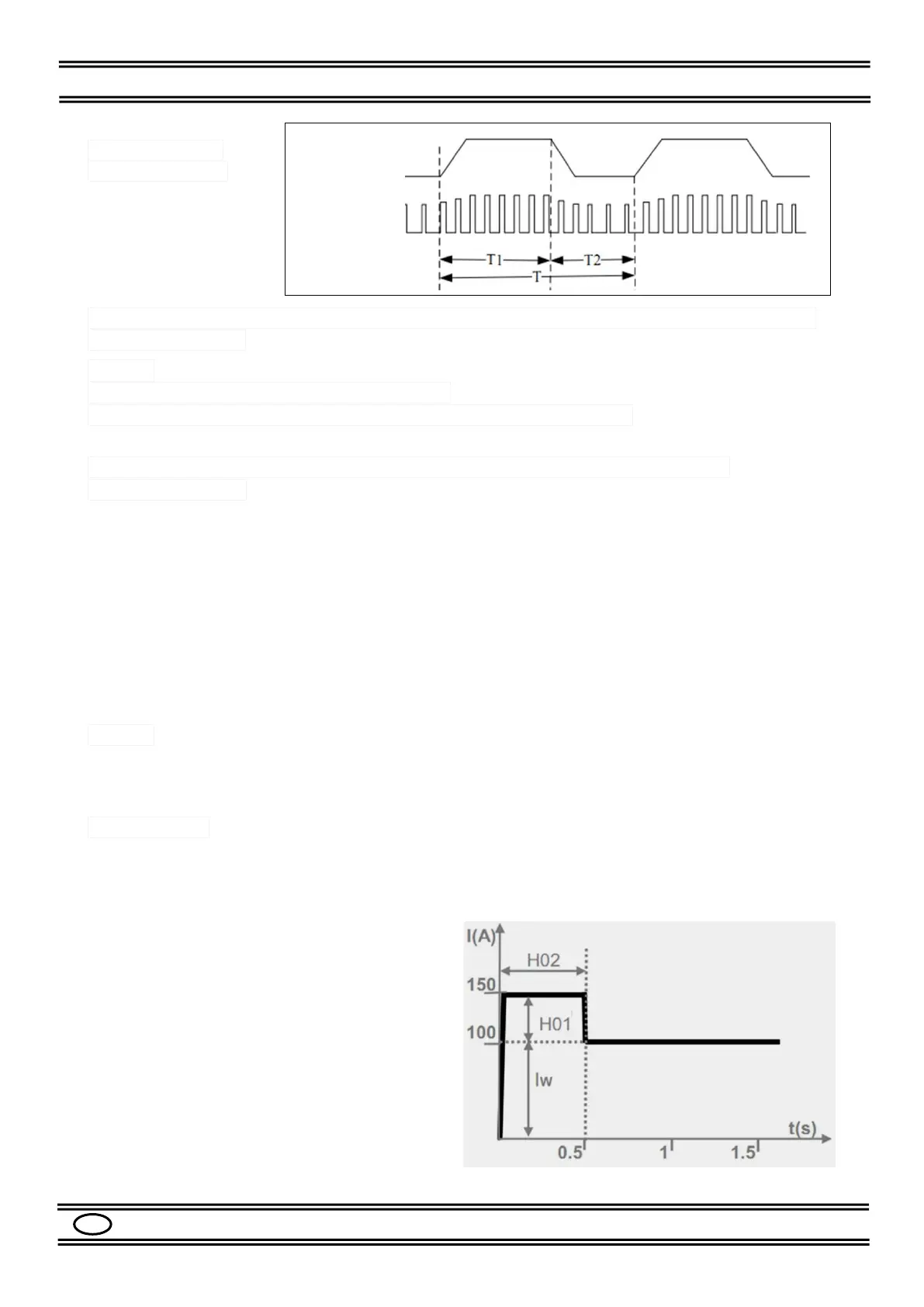

H01, H02 - HOT START (only in MMA mode)

This function provides the following benefits:

- Improves the ignition, even when using electrodes with poor ignition properties

- Improve the fusion of the base metal in the start-up, which means fewer defects at the cold

start of welding.

- Prevents most of slag inclusions.

Refer to the figure on the side.

During the HOT START time, indicated

with “H02”, the welding current can be

increased. This value, "H01", can be

adjusted from 1 to 100% more than the

current of welding set.

In the example in the figure, the set current

is 100A. By setting a current of HOT START

(H01) of 50%, and a time (H02) of 0.5 s, an

initial current of 100A + (50% of 100A) = 150A

for 0.5 s.

Loading...

Loading...