8 Trouble-shooting

WARNING

Improper work to remedy faults

Risk of injury!

▷ For any work to remedy faults observe the relevant information in this manual

or in the relevant accessory manufacturer's product literature.

If problems occur that are not described in the following table, consultation with the

customer service is required.

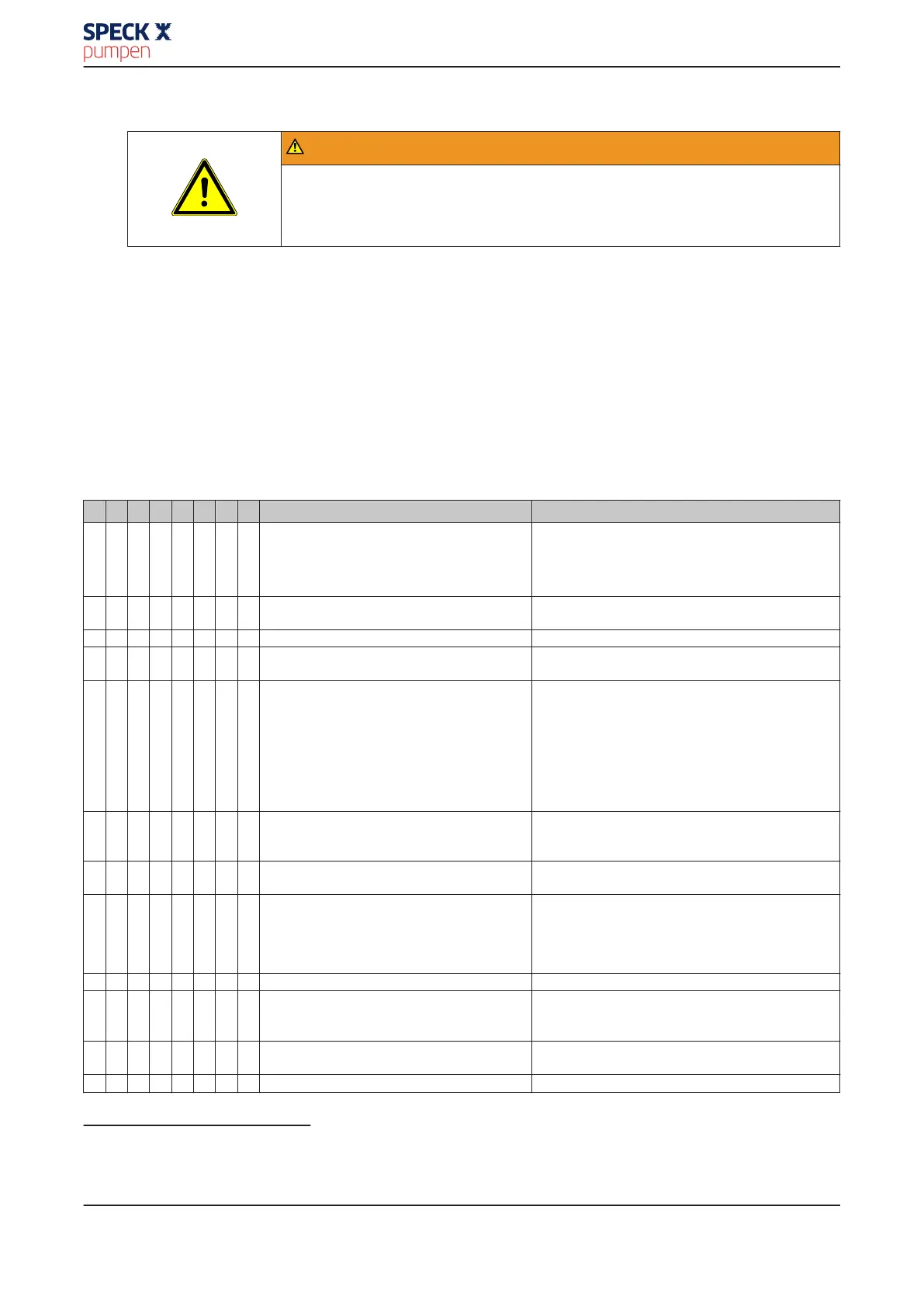

Pump delivers insufficient flow rate

Motor is overloaded

Excessive discharge pressure

Increased bearing temperature

Leakage at the pump

Excessive leakage at the shaft seal

Vibrations during pump operation

Impermissible temperature increase in the pump

Table 19: Trouble-shooting

A B C D E F G H Possible cause

Remedy

5)

✘ - - - - - - - Pump delivers against an excessively

high pressure.

Re-adjust to duty point.

Check system for impurities.

Fit a larger impeller.

6)

Increase the speed (turbine, I.C. engine).

✘ - - - - - ✘ ✘ Pump or piping are not completely

vented or primed.

Vent and/or prime.

✘ - - - - - - - Supply line or impeller clogged Remove deposits in the pump and/or piping.

✘ - - - - - - - Formation of air pockets in the piping Alter piping layout.

Fit vent valve.

✘ - - - - - ✘ ✘ Suction lift is too high/NPSHavailable

(positive suction head) is too low.

Check/alter fluid level.

Install pump at a lower level.

Fully open the shut-off element in the suction

line.

Change suction line, if the friction losses in

the suction line are too high.

Check any strainers installed/suction opening.

Observe permissible speed of pressure fall.

✘ - - - - - - - Air intake at the shaft seal Supply external barrier fluid, if necessary, or

increase barrier fluid pressure.

Replace shaft seal.

✘ - - - - - - - Wrong direction of rotation Check the electrical connection of the motor

and the control system, if any.

✘ - - - - - - - Speed is too low.

- Operation with frequency inverter

- Operation without frequency inverter

- Increase voltage/frequency at the FI in the

permissible range.

- Check voltage.

✘ - - - - - ✘ - Wear of internal components Replace worn components by new ones.

- ✘ - - - - ✘ - Pump back pressure is lower than

specified in the purchase order.

Re-adjust to duty point.

In the case of persistent overloading, turn

down impeller.

6)

- ✘ - - - - - - Density or viscosity of fluid handled

higher than stated in purchase order

Contact the manufacturer.

- - - - - ✘ - - Use of unsuitable shaft seal materials

Change the material combination.

6)

A

B

C

D

E

F

G

H

5)

Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

6)

Contact the manufacturer.

8 Trouble-shooting

Normblock

47 of 58

Loading...

Loading...