CAUTION

Welding beads, scale and other impurities in the piping

Damage to the pump!

▷ Free the piping from any impurities.

▷ If necessary, install a filter.

▷ Comply with the instructions set out in (⇨ Section 7.2.2.2 Page 38) .

3. Check that the inside of the pump is free from any foreign objects. Remove any

foreign objects.

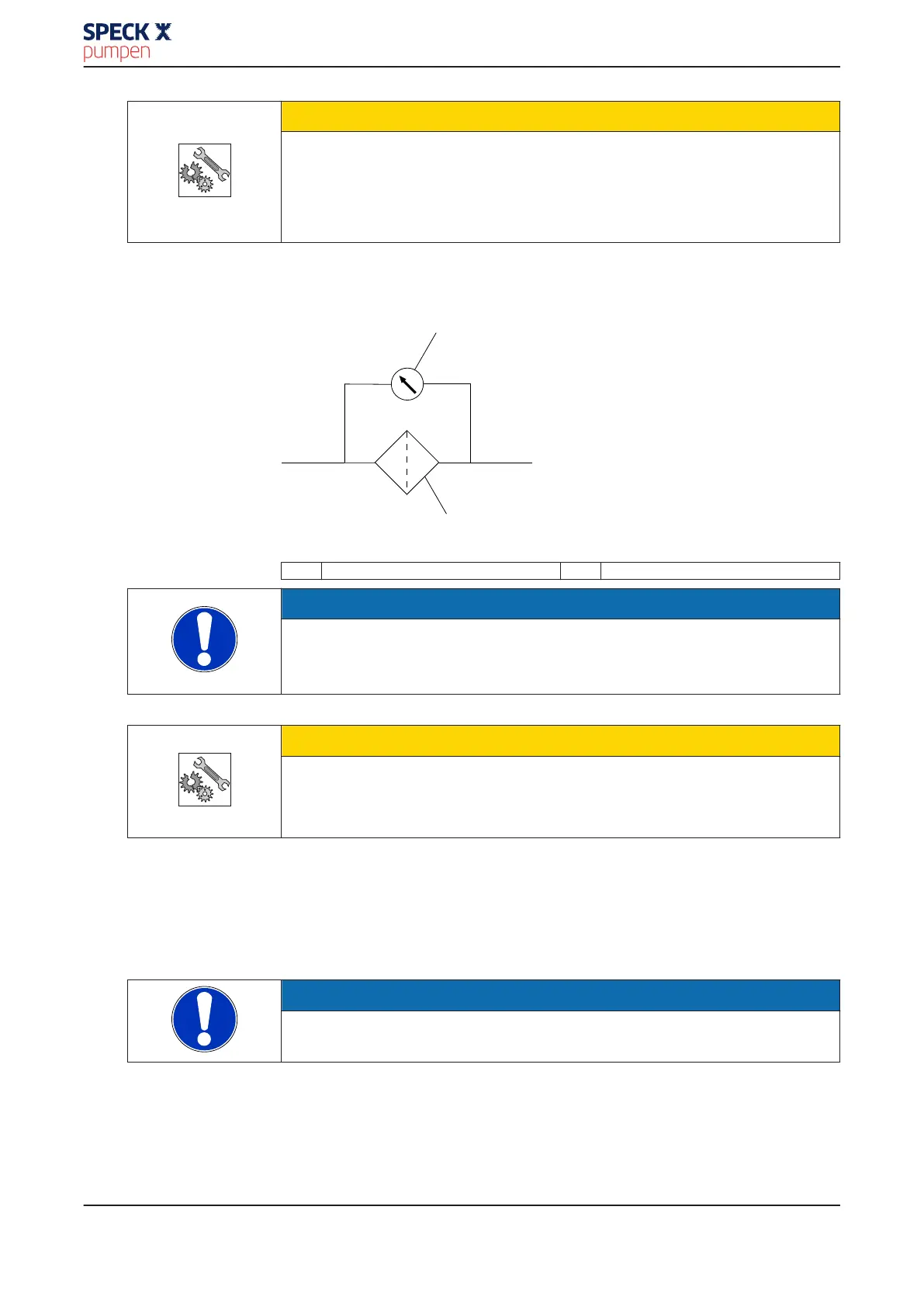

4. If required, install a filter in the piping (see drawing: Filter in the piping).

Fig. 6:

Filter in the piping

1

Differential pressure gauge 2 Filter

NOTE

Use a filter with laid-in wire mesh of 0.5 mm x 0.25 mm (mesh size x wire diameter)

made of corrosion-resistant material.

Use a filter with a filter area three times the cross-section of the piping.

Conical filters have proved suitable.

5. Connect the pump nozzles to the piping.

CAUTION

Aggressive flushing and pickling agents

Damage to the pump!

▷ Match the cleaning operation mode and duration for flushing and pickling

service to the casing and seal materials used.

5.4.2 Permissible forces and moments at the pump nozzles

No piping-induced forces and moments (from warped pipelines or thermal

expansion, for example) must act on the pump.

5.4.3 Vacuum balance line

NOTE

Where fluid has to be pumped out of a vessel under vacuum, installing a vacuum

balance line is recommended.

The following rules apply to vacuum balance lines:

▪ Minimum nominal line diameter 25 mm.

▪ The line extends above the highest permissible fluid level in the vessel.

5 Installation at Site

24 of 58

Normblock

Loading...

Loading...