From a physical point of view, these local sources act like a thermal capacitor placed in

parallel to the thermal model of the LPS25HB and they can give a contribution to the local

temperature that is different from the environmental one.

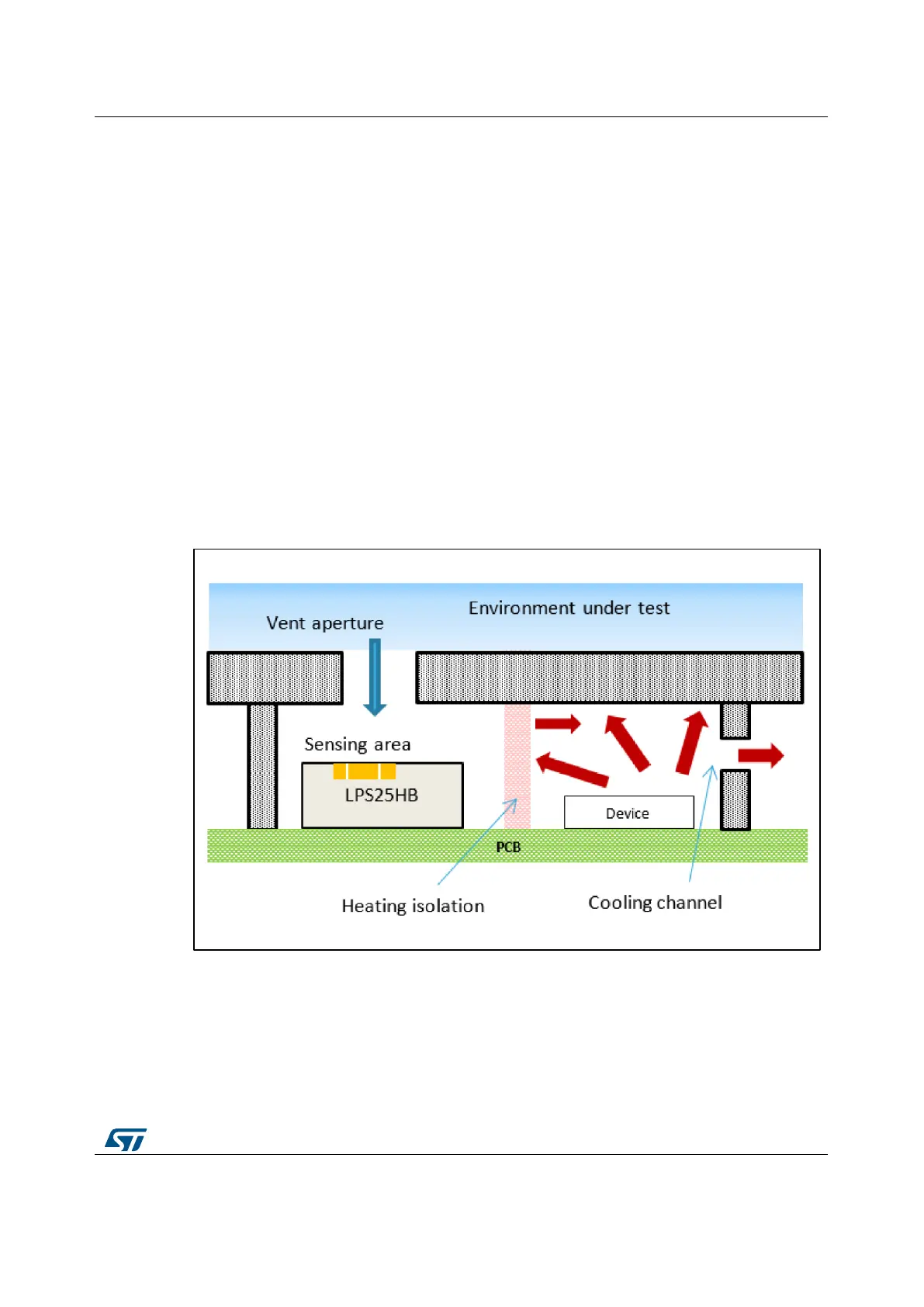

Depending on the heat sources location and the heating mechanism propagation, we can

distinguish the propagation related to different mechanisms as described below.

Heating convection

Local thermal sources around the sensor can modify the pressure and temperature

measurement by heating radiation.

Typical sources are as follows:

other sensors and devices like close the pressure sensor

power management devices

processors and microcontrollers

LCD displays that, in particular provide a significant temperature gradient between the

environment and the dead volume inside the system

Therefore the sensor has to be placed at the correct distance from these sources, and to

guarantee the appropriate isolation, it is recommended to adopt inside the embodiment,

heating isolation structures as described in Figure 4: "Heating isolation implemented for

protecting the sensor". It also suggested, according to the specific layout to implement as

well vent aperture close the heat source, acting as cooling channels.

Figure 4: Heating isolation implemented for protecting the sensor

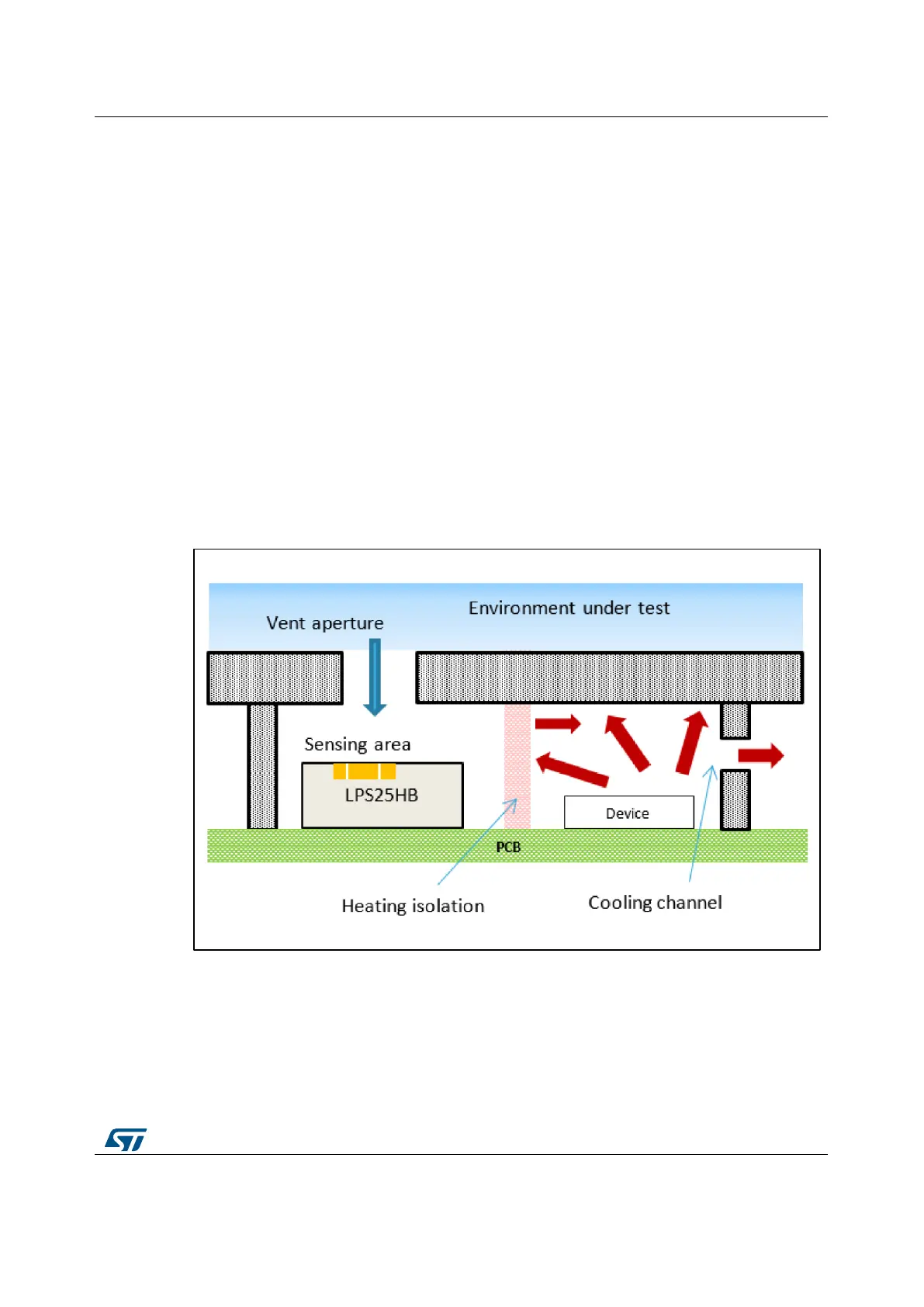

Looking at a section of the sensor housing, Figure 5: "Top view of the sensor housing: on

the left a correct design with the heat isolation, on the right a wrong design" shows a good

design with the heating isolation structure on the left; the heat source is far from the sensor

and a thermal protection structure is placed in the middle. On the right, a wrong design is

described, determining the sensor heating because of the heat radiation coming from the

component nearby.

Loading...

Loading...