9.2 Crystal oscillator

Use the application note: Oscillator design guide for STM8S, STM8A and STM32 microcontrollers (AN2867), for

further guidance on how to layout and route crystal oscillator circuits.

9.3 Power supply decoupling

An adequate power decoupling for STM32H723/33, STM32H725/35 and STM32H730 microcontrollers is

necessary to prevent excessive power and ground bounce noise. Refer to Section 2 Power supplies.

The following recommendations shall be followed:

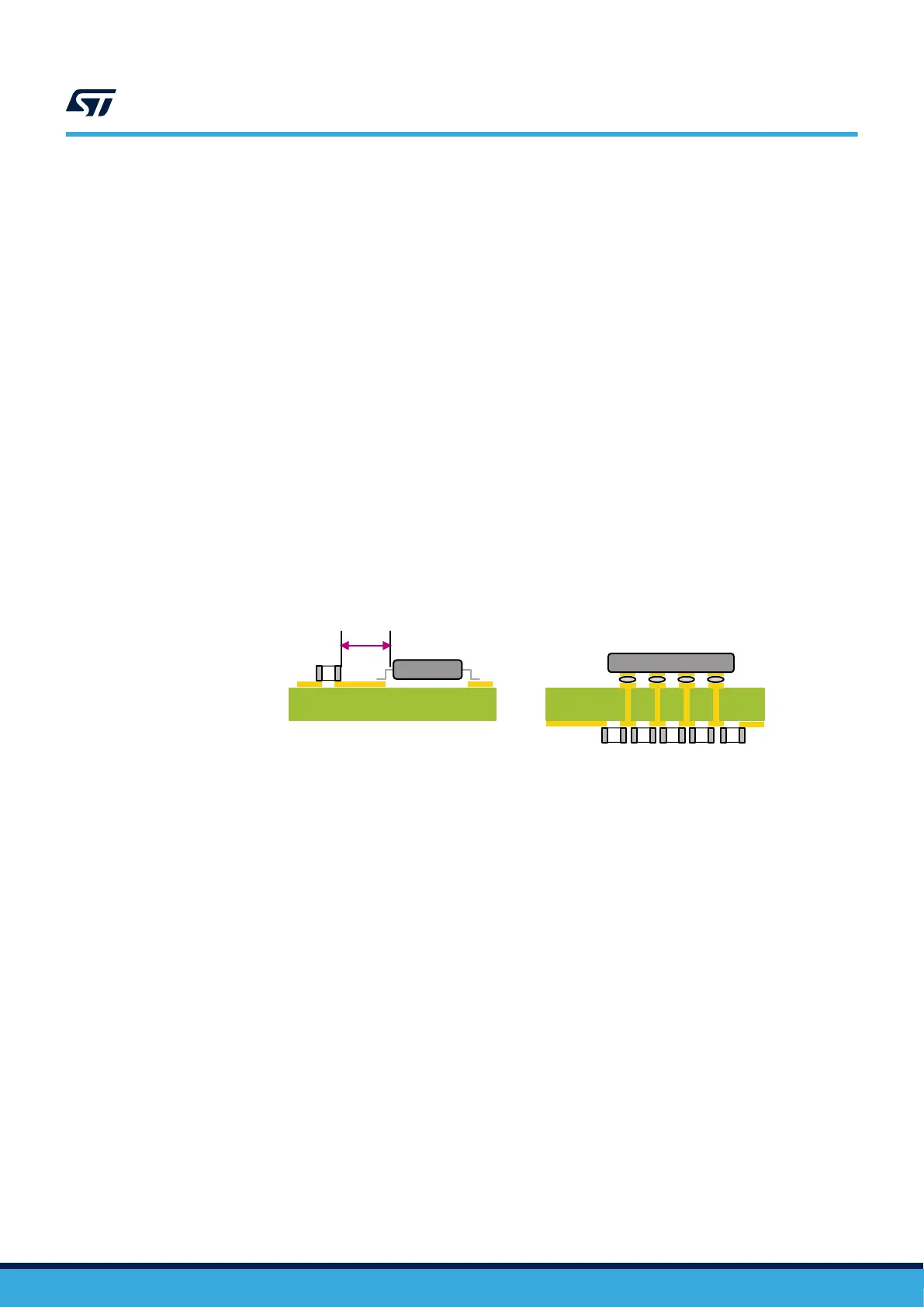

• Place the decoupling capacitors as close as possible to the power and ground pins of the MCU. For BGA

packages, it is recommended to place the decoupling capacitors on the opposing side of the PCB (see

Figure 19. Decoupling capacitor placement depending on package type).

• Add the recommended decoupling capacitors to as many V

DD

/V

SS

pairs as possible.

• Connect the decoupling capacitor pad to the power and ground plane with a wide and short trace/via. This

reduces the series inductance, maximizes the current flow and minimizes the transient voltage drops from

the power plane and in turn reduces the ground bounce occurrence.

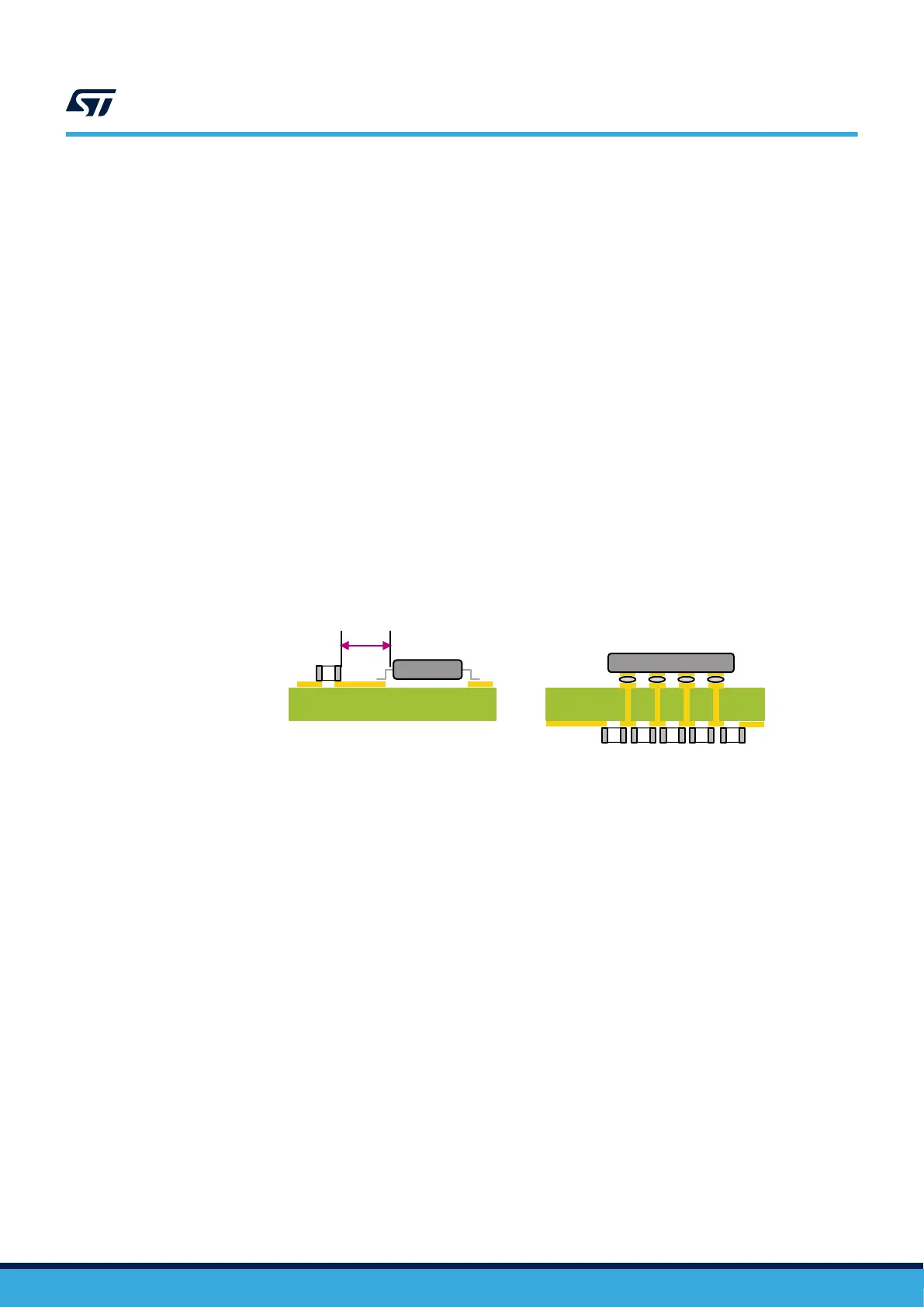

Figure 20. Example of decoupling capacitor placed underneath shows an example of decoupling capacitor

placement underneath STM32H723/33, STM32H725/35 and STM32H730 microcontroller, closer to the pins and

with less vias.

Figure 19. Decoupling capacitor placement depending on package type

PCB PCB

Decoupling

capacitor

Decoupling capacitor and STM32

MCU on the same side of the

package (all packages except BGA)

Distance to

be minimized

STM32

Decoupling capacitor and STM32

MCU on the opposite sides of the

package (BGA package )

STM32

Decoupling

capacitor

AN5419

Crystal oscillator

AN5419 - Rev 2

page 35/50

Loading...

Loading...