G

B

16

residualcurrentdevice(R.C.D.)atthesocketoutlet.

Note: If the mains cable requires replacing it must be replaced with an

identicaloneandfittedbyaqualifiedperson.

START-UP AND USE

4

•Check for correspondence between the compressor plate data with the

actual specifications of the electrical system.Avariation of ± 10% with

respectoftheratedvalueisallowed.

•Inserttheplugofthepowercableinasuitablesocket(fig. 6)checkingthat

the button of the pressure switch located on the compressor is in the OFF

«O»position.

•Check the oil level by meansoftheoil dipstick (figures 7a- 7b), and if

necessarytopup.

•Atthispoint,thecompressorisreadyforuse.

•Operating on the switch of thepressureswitch (fig. 1), the compressor

starts,pumpingairintothereceiverthroughthedeliverypipe.

•When the upper calibration value (set by the manufacturer) has been

reached,thecompressorstops,ventingtheexcessairpresentinthehead

andinthedeliverypipethroughavalvelocatedunderthepressureswitch.

This facilitates subsequent restart due to the absence of pressure in the

head.Whenairisused,thecompressorrestartsautomaticallywhenthe

lowercalibrationvalueisreached(2barbetweenupperandlower).

•Thepressureinthereceivercanbecheckedonthegaugeprovided(fig. 8).

•The compressor continues to operate according to this automatic cycle

untiltheswitchofthepressureswitchisturned.

•Always wait at least 10 seconds from when the compressor has been

switchedoffbeforerestartingthis.

•All compressors are fitted with a pressure reducer. Operating on the

knobwiththetapopen(turningitinaclockwisedirectiontoincreasethe

pressure and in a counterclockwise direction to reduce this, fig. 9a),air

pressurecanberegulatedsoastooptimizeuseofpneumatictools.After

settingthe value required,thering-nutunderneathmust be tightenedto

fastentheknob(fig. 9b).

•Thevaluesetcanbecheckedonthegauge.

•Please check that the air consumption and the maximum working

pressure of the pneumatic tool to be used are compatible with the

pressure set on the pressure regulator and with the amount of air

supplied by the compressor.

•Always pull out the plug and drain the receiver once you have completed

yourwork(figures 10-11).

MAINTENANCE

5

•BEFORE CARRYING OUT ANY OPERATION, ALWAYS PULL OUT THE

PLUG AND DRAIN THE RECEIVER COMPLETELY (figures 10-11).

•Checkthatallscrews(inparticularthoseoftheheadoftheunit)aretightly

drawnup(torque10Nm=1.02Kgm).

Thecontrolmustbeperformedbeforethefirststart-upofthecompressor

and subsequently before the first intensive use in order to restore the

correctclosingtorquevaluemodifiedasaresultofheatexpansion.

•After loosening any safety screws, clean the intake filter according to

the type of working environment and at least every 100 hours (figure

12).Ifnecessary,replacethefilterelement(cloggingofthefilterreduces

compressorperformanceandaninefficientfiltercausesincreasedwear).

•Replace the oil after the first 100 hours of operation and every 300 hours

subsequently(figures 13a-13b-13c).Remembertochecktheoillevelat

regularintervals.

Use SAE 40.(For cold climates, SAE 20 is recommended). Never mix

differentgradeoils.Iftheoilchangescolor(whitish=presenceofwater;

dark=overheated),itisgoodpracticetoreplacetheoilimmediately.

•Periodically(orafterworkingwiththecompressorformorethananhour),

drainthe condensate that forms insidethe receiver (fig. 11)due to the

humidityintheair.Thisprotectsthereceiverfromcorrosionanddoesnot

restrictitscapacity.

•Spent oil (lubricated models) and condensate MUST BE DISPOSED

OF in accordance with environmental protection regulations and current

legislation.

The compressor must be disposed in conformity with the methods

provided for by local regulations.

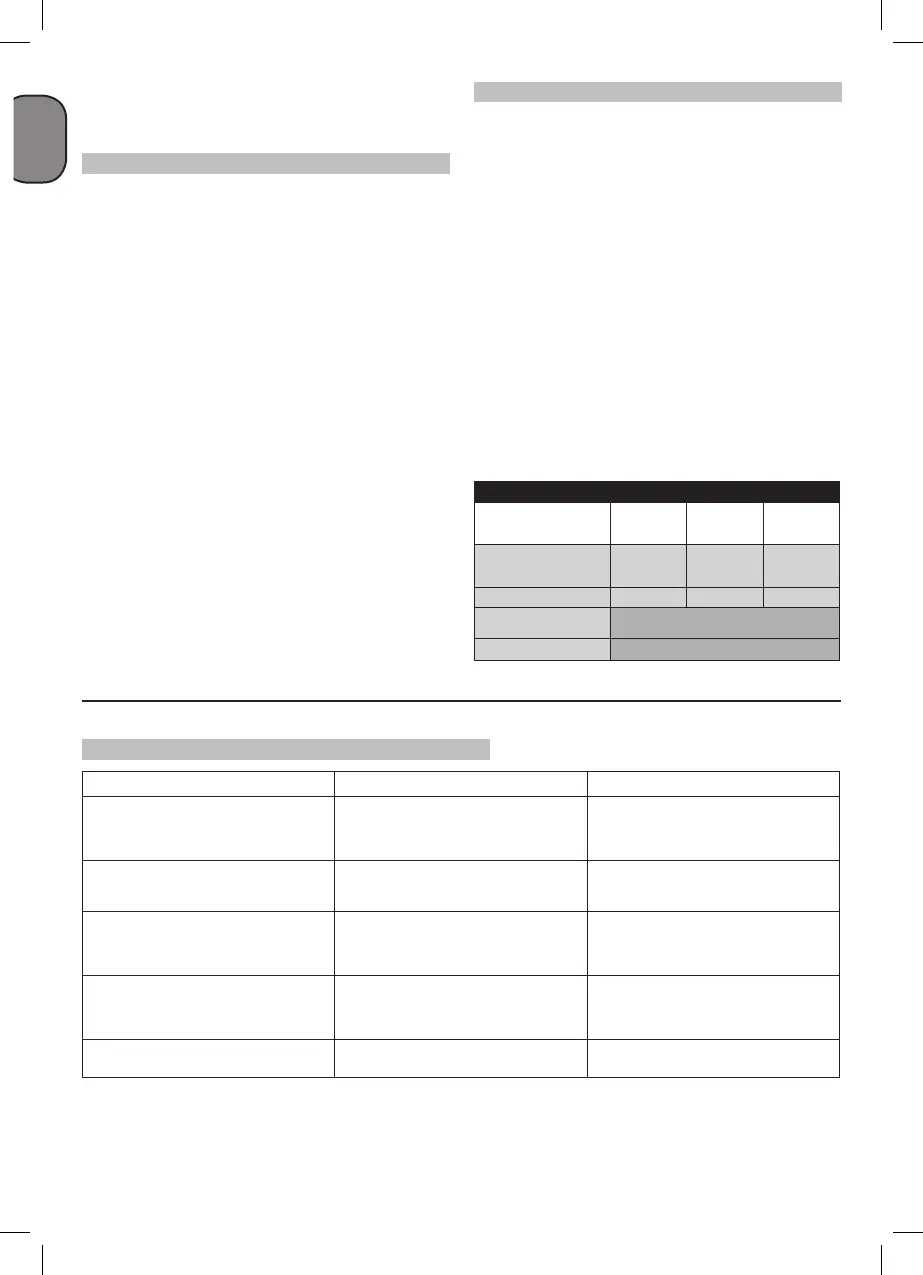

TABLE 1 – MAINTENANCE

FUNCTION

AFTER THE

FIRST 100

HOURS

EVERY 100

HOURS

EVERY 300

HOURS

Cleaning of intake filter and/

or substitution of filtering

element

●

Change of oil

● ●

Tightening of head tension

rods

Atstart-upandafterthefirsthourofwork

Draining tank condensate Periodically and at the end of work

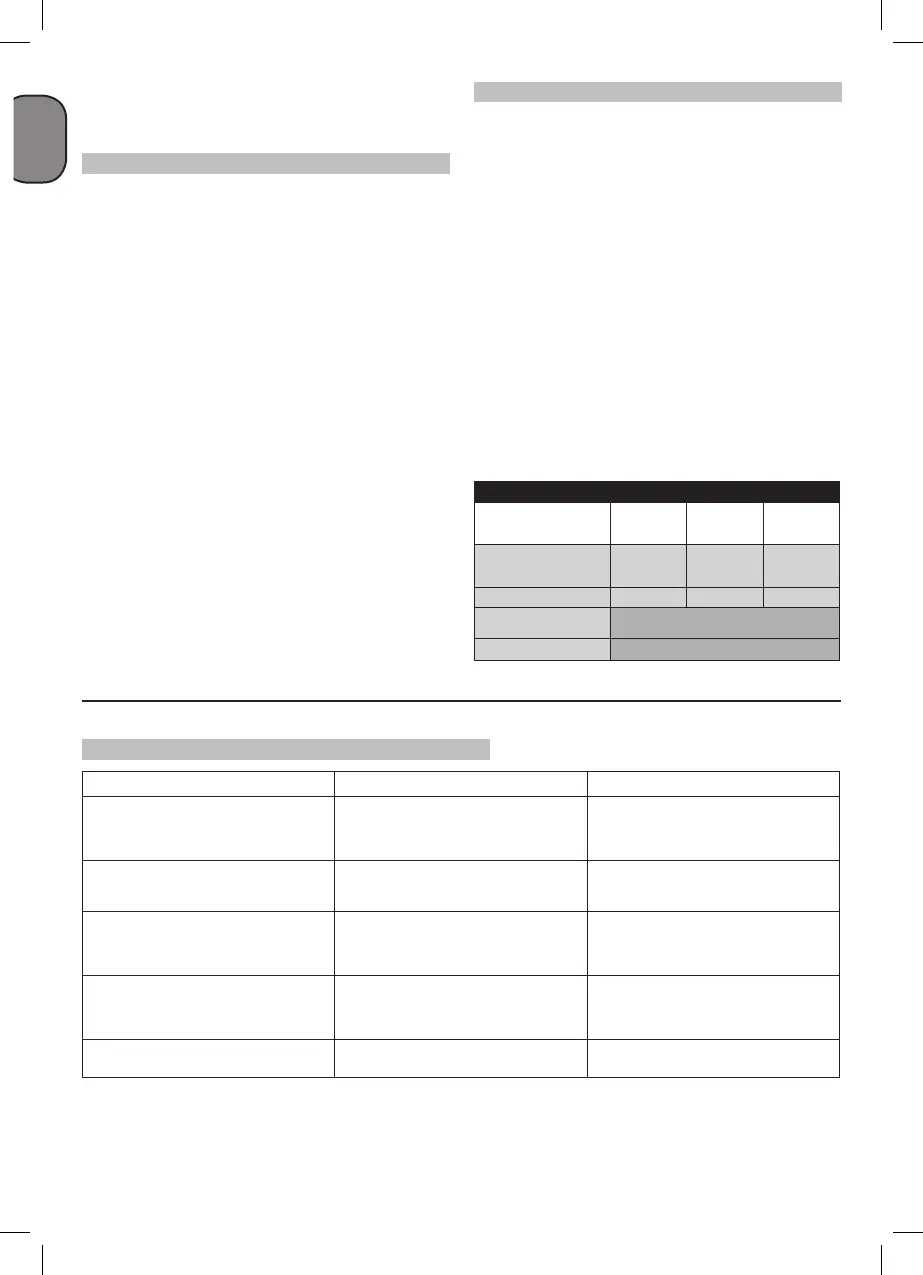

POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

6

FAULT CAUSE REMEDY

Leakage of air from the valve of the pressure

switchwiththecompressoroff.

Check valve that, due to wear or dirt on the seal,

doesnotperformitsfunctioncorrectly.

Unscrewthehexagonalheadofthecheck

valve, clean the valve seat and the special

rubberdisk(replaceifworn).Reassembleand

tightencarefully(gures14a-14b).

Reductionofperformance.Frequentstart-up.

Lowpressurevalues.

Excessiveperformancerequest,checkforany

leaksfromthecouplingsand/orpipes.Intake

ltermaybeclogged.

Replacethesealsofthetting,cleanorreplace

thelter.

The compressor stops and restarts

automaticallyafterafewminutes.

Tripping of the thermal cutout due to

overheatingofthemotor.

Cleantheairductsintheconveyor.Ventilate

theworkarea.Resetthethermalcutout.On

lubricated type models, check oil level and

quality.

After a few attempts to restart, the compressor

stops.

Tripping of the thermal cutout due to

overheatingofthemotor(removalofthe

plug with the compressor running, low power

voltage).

Activatetheon/offswitch.Ventilatethework

area.Waitafewminutes.Thecompressorwill

restartindependently.Removeanypowercable

extensions.

The compressor does not stop and the safety

valveistripped.

Irregular functioning of the compressor or

breakageofthepressureswitch.

Remove the plug and contact the Service

Center.

AnyothertypeofoperationmustbecarriedoutbyauthorizedServiceCenters,requestingoriginalparts.Tamperingwiththemachinemayimpairitssafety

andinanycasemakethewarrantynullandvoid.

Warranty and repair.

Intheeventofdefectivegoodsorrequirementsforspareparts,kindlycontactthesalespointwhereyoumadeyourpurchase.

Loading...

Loading...