12 ► MB05 User Manual

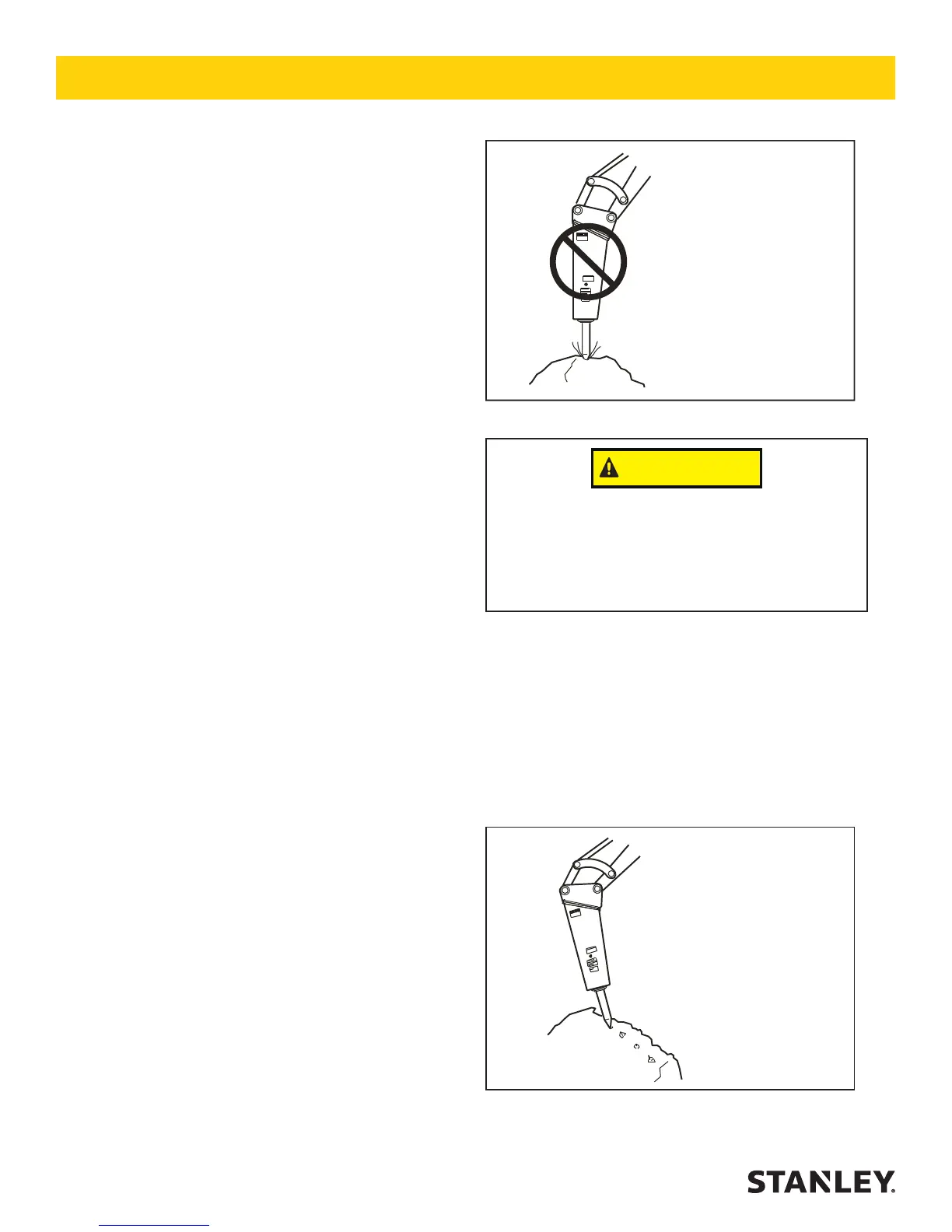

Use a “scoring” method of breaking when cracking

the material becomes difcult. This technique involves

striking the rock or concrete at several places along a

line where you want the crack to occur. Most materials

break sooner when struck several places along a line

than when struck repeatedly in one location. On each

line, the breaker tool should be continually repositioned.

Practice determines the best length of time to stay in

one spot. (15 – 20 seconds) and how far to move the

breaker tool.

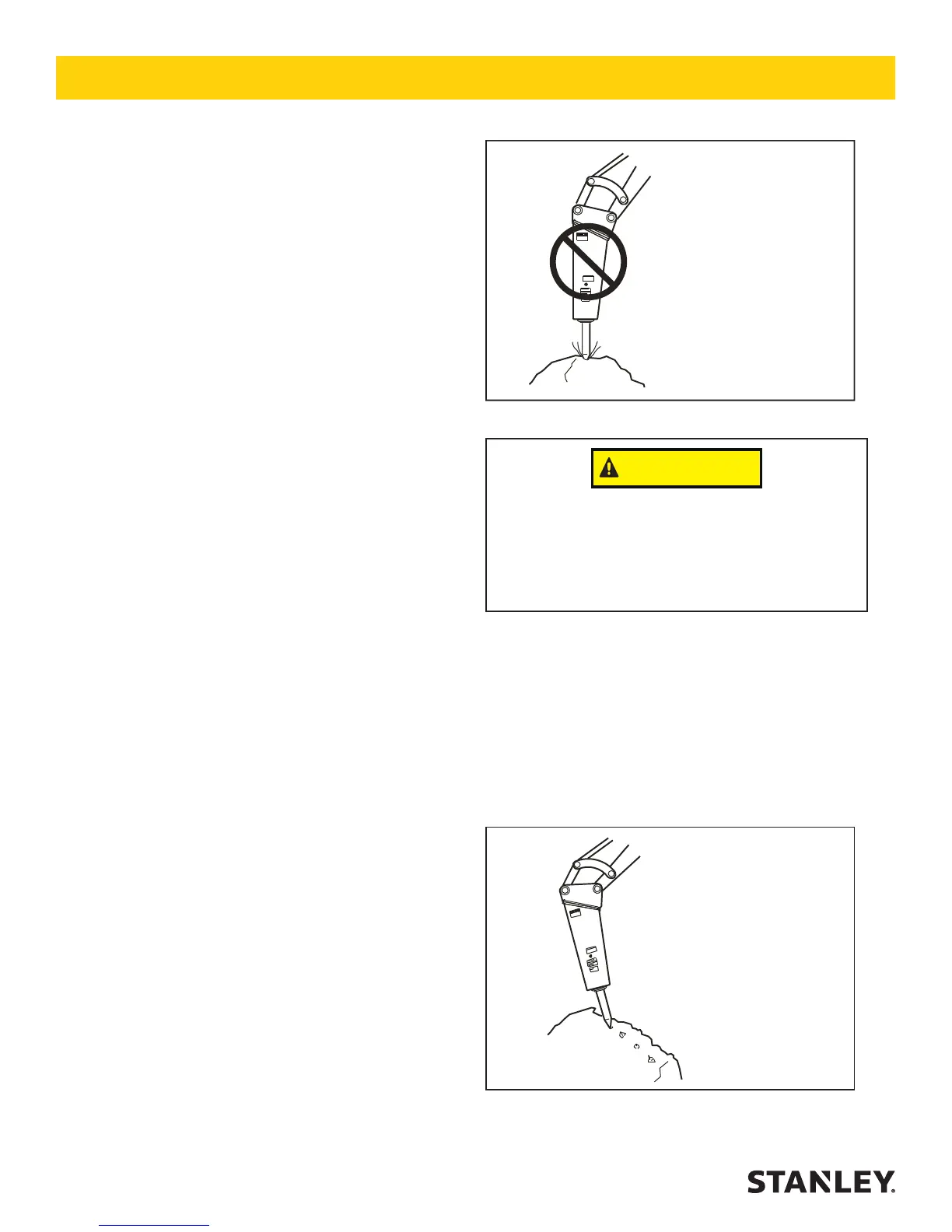

Do not break continuously

in one place.

15 – 20 seconds. If breakout does not occur within this

time, move the breaker to another position.

On at material such as concrete runways, starting to

break in the middle of the material may cause vibrations

to be transmitted throughout the breaker and excavator

because the material has no place to break to. Always

try to start at a point which will permit the material to

break out.

MAINTAIN DOWN PRESSURE

Maintaining hard contact with the surface of the material

to be broken in addition to maintaining adequate “down

force” is very important. Always keep “down pressure”

or “down force” on the point of the breaker by lifting the

wheels, tracks, or stabilizers slightly above the ground.

This method takes the “slack” out of the bracket and

boom pivots, and reduces the impact on the pivots in

the boom.

The operator needs to be constantly aware of the amount

of down pressure being applied and be able to adjust it

if necessary. Not enough down pressure results in low

production and accelerates wear and tear on the equip-

ment. Too much down pressure may cause the breaker

housing to violently crash into the broken material when

“break-through” occurs.

In any breaking job, the operator should make every ef-

fort to “follow” the breaker with “down pressure” as the

machine breaks farther into the material. The breaker

should be stopped as soon as “break-through” occurs or

if it is apparent that good solid blows are not occurring.

BREAKING

The operator should note the sound of the blow when

the breaker is running. With experience, the operator will

be able to tell the difference between a good solid blow

and a hollow sounding blow. A hollow blow means that

solid blows are not occurring and breaker should be re-

positioned.

Continuous tool penetration usually does not do much

good. If the material does not break with 3 – 6 inches of

tool penetration, it usually won’t break with full penetra-

tion. The time used for additional penetration could be

better used to strike blows in another place.

Many materials do not respond well to continued ham-

mering in one place. The breaker tool should be repo-

sitioned on the work each time the tool penetrates but

does not crack the material.

Continuous penetration in the same area for lengthy

periods will create excessive temperatures at the tip

of the tool bit resulting in loss of temper (hardness)

of the bit, mushrooming of the tip of the bit and may

lead to failure of the bit.

OPERATION

Loading...

Loading...