16 ► MB05 User Manual

DAILY MAINTENANCE CHECKS

Check for loose or missing fasteners. Tighten or replace

as needed.

Inspect tool retaining pins and pockets for wear.

Check for hydraulic leaks at all ttings and hoses. Re-

place any defective hoses.

Apply grease to the grease tting in the lower body each

morning. Grease as needed throughout the work day.

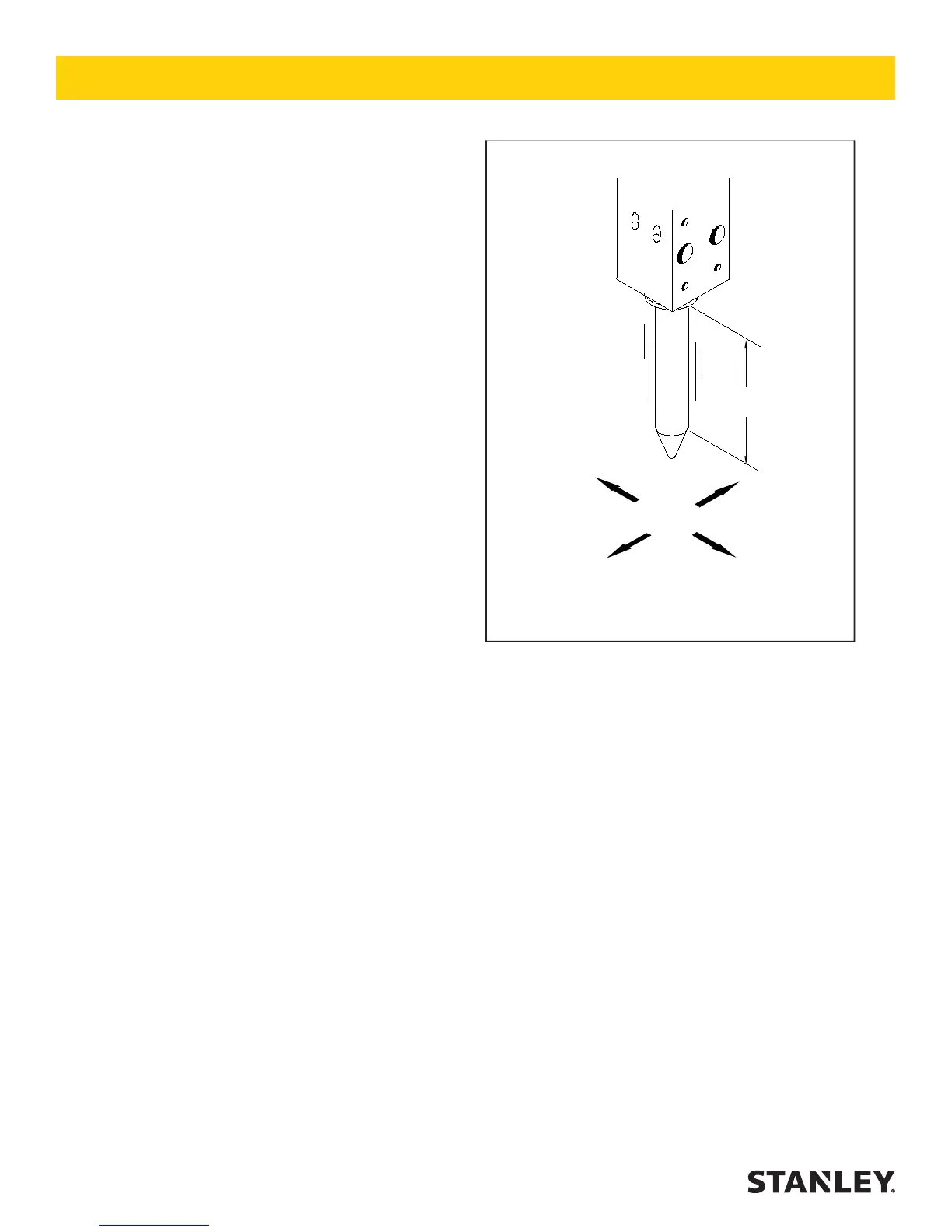

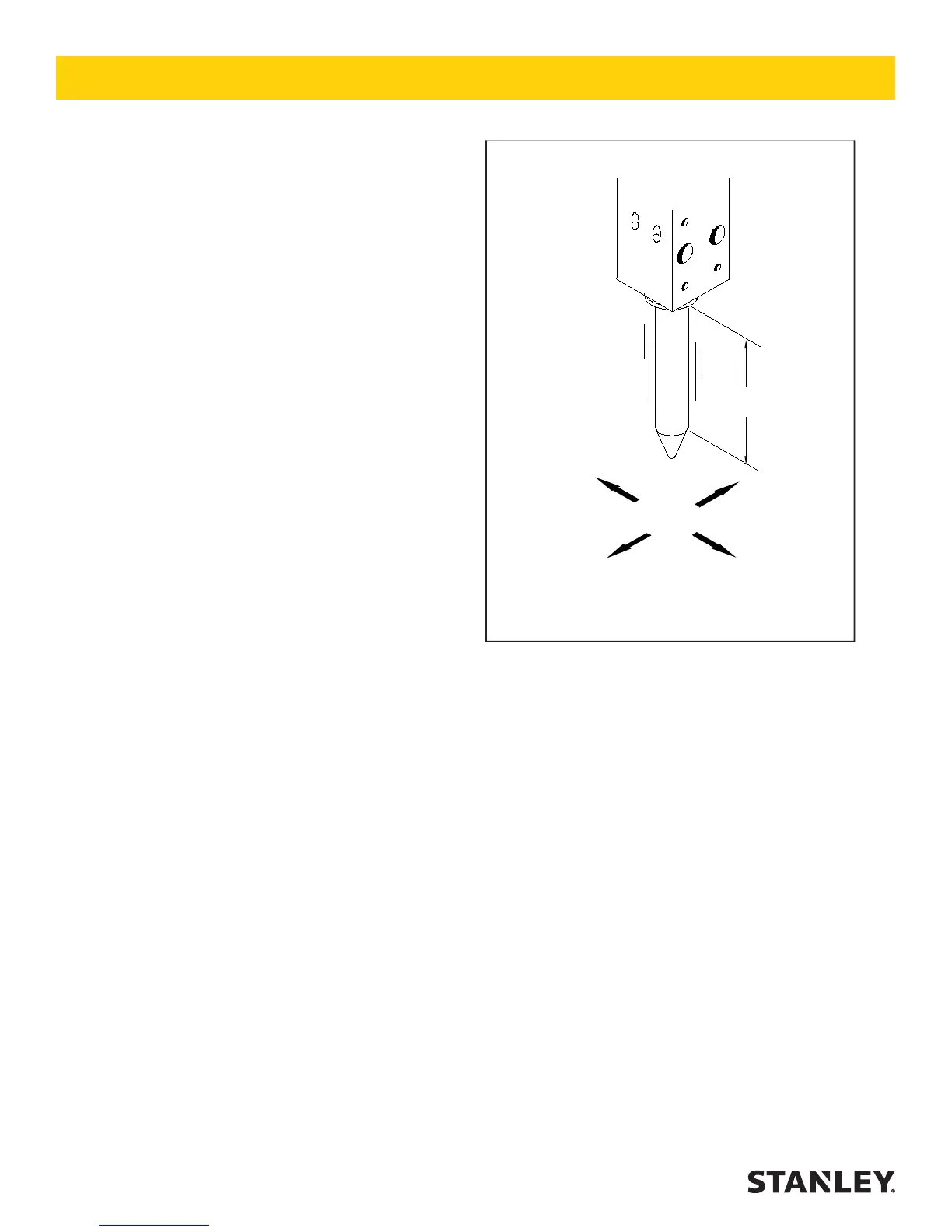

TOOL STOP AND LOWER BUSHING

Inspect the tool stop and lower bushing for excessive

galling and metal pickup on the tool bit. Also check for

cracks. If cracks are present, the part must be replaced.

The extent of wear of the tool stop and lower bushings

and the tool bit can be checked by moving a NEW tool

bit back and forth and measuring the gap between the

tool bit and the lower bushing. If the gap is more than

.250 in./6 mm, the upper bushing, lower bushing and

tool bit should be replaced. A gap in excess of .250 in./6

mm will cause damage to the piston. Do not just replace

the tool bit or the lower bushing individually as this will

result in premature wear of the replaced component. It is

recommended to replace ALL worn components.

Move the tool bit back and forth and measure the

gap between tool bit and lower bushing. (Use a new

tool bit.)

1/4 in. max.

18 inches

MAINTENANCE

Loading...

Loading...