MB05 User Manual ◄ 19

METAL-TO-METAL CONTACT

Extreme caution should be used to avoid scratches or

gouges on the surface of the tool. These areas create a

stress concentration Metal-to-Metal Contact point, thus

weakening the tool.

Another form of metal-to-metal contact is galling, which

usually occurs from the lack of lubrication. Special care

should be taken to keep the tool shank lubricated every

two (2) to three (3) hours.

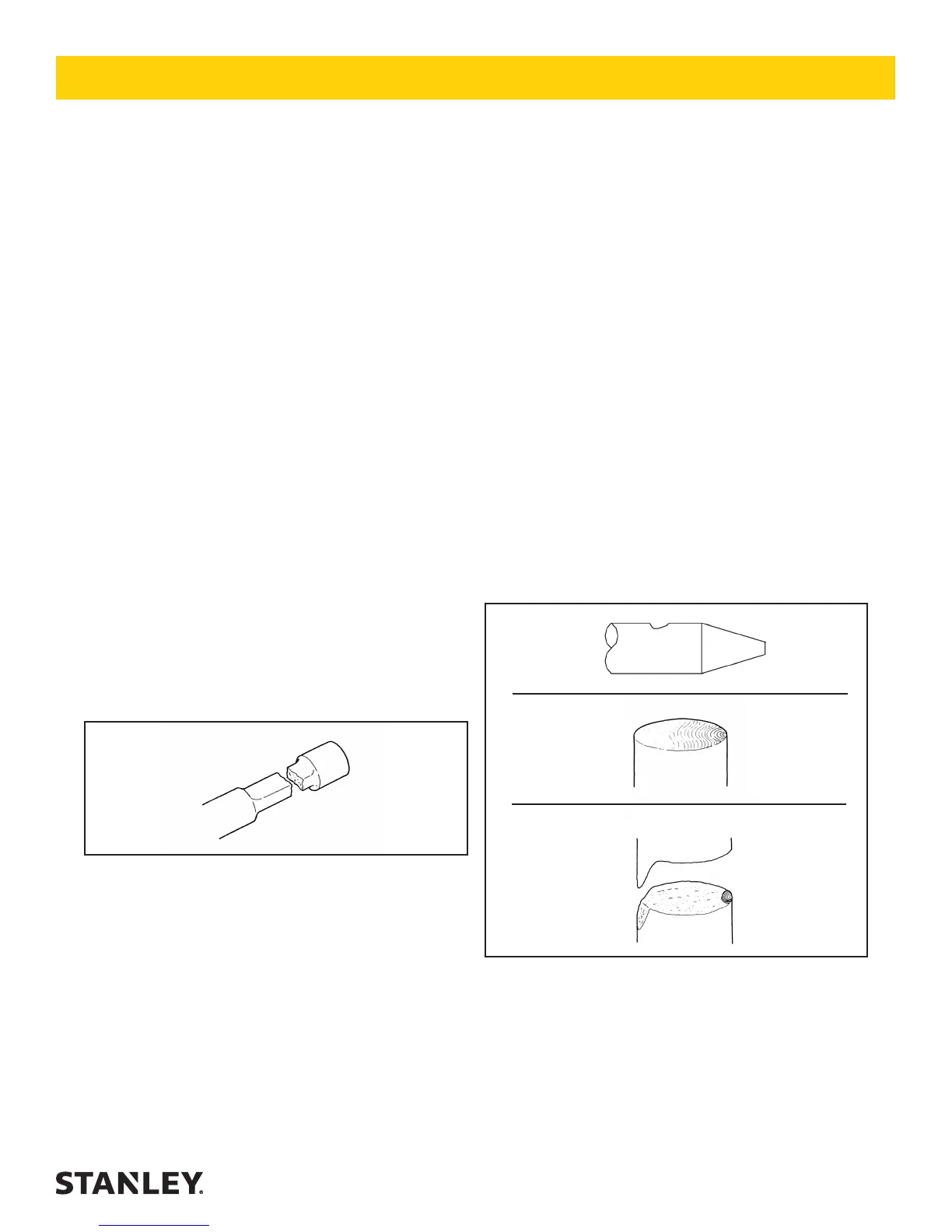

Steel failures that were caused by surface damage take

two main forms. The simplest form is caused by deep

scratches on working steel surface. The broken surface

has a shell pattern around the starting point of failure,

similar to the one in the fatigue failure. The other parts of

the broken surface are brittle. These failures work slowly

through the steel until it suddenly parts completely.

The second form of failure caused by surface damage

occurs when there are deep scratches on working steel

surface and there was also excessive bending stress.

The broken surface also shows the shell pattern, but the

other parts of the broken surface are brittle and usually

have a “lip” like that in a stress failure.

Tool bits are made and heat treated to specication.

Tool bits, however well made, are wear parts, and are

used in the most destructive applications. Even when

the hydraulic breaker is used properly, and the operator

is an experienced one, a tool bit may become damaged.

When a tool bit has been damaged, it is useful to de-

termine the cause immediately in order to prevent the

damage from occurring again.

All Stanley tool bits are machined and hardened for

maximum performance. Care must be taken to maintain

the tools original condition for optimum productivity and

life expectancy. It is not uncommon for an operator who

is unfamiliar with using a hammer to break a point. This

is part of the learning experience.

Listed below are several methods to determine tool fail-

ure and will quickly aid in warranty determination.

TOOL FAILURE NOT COVERED

UNDER WARRANTY

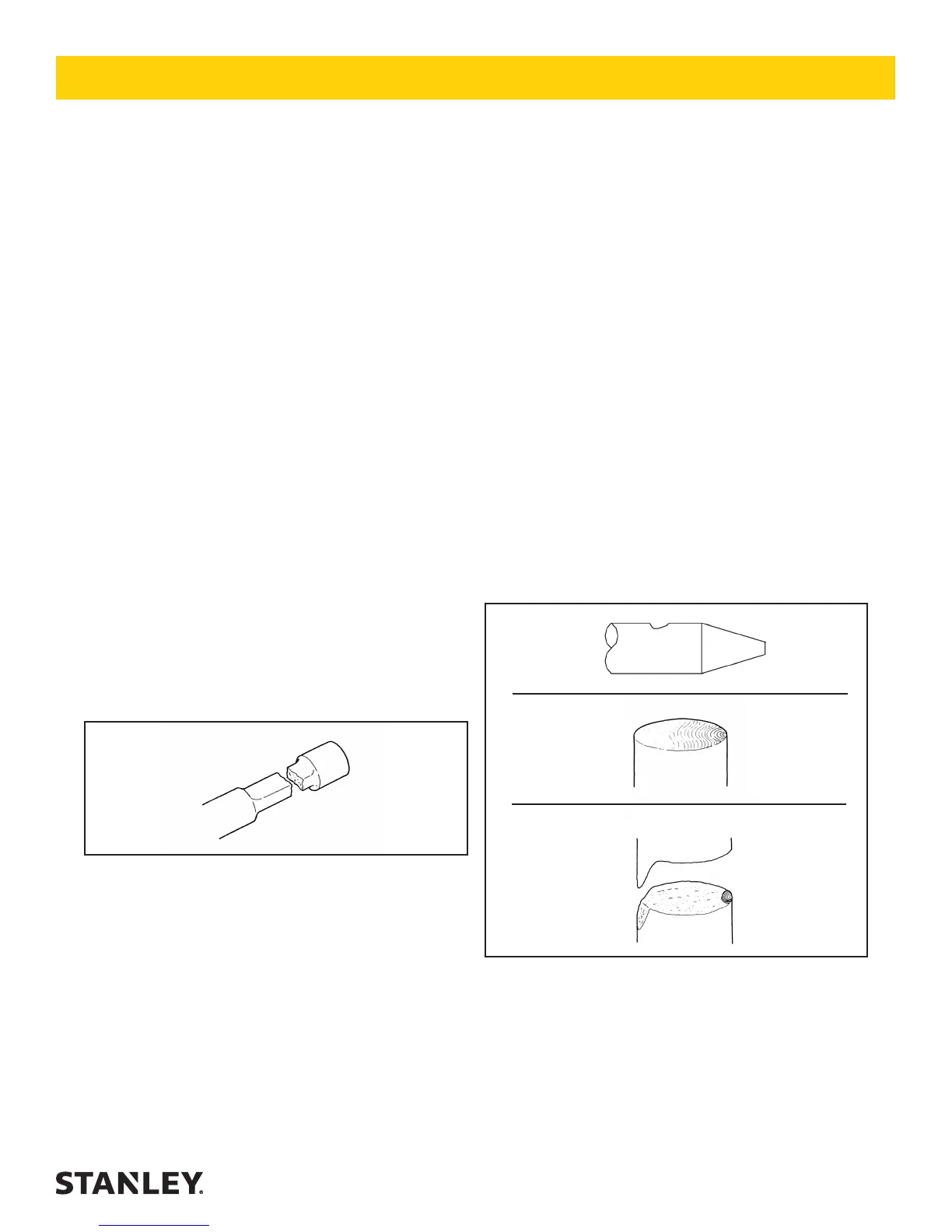

BLANK FIRING OR FREE RUNNING

This occurs when the tool is not in proper contact with

the work, thus causing the energy produced by the ham-

mer to be concentrated on the tool retainer(s) and the

retainer slot(s) on the tool itself. Caution should be used

to prevent the hammer from sliding off slanted surfaces

or when breaking through thin material.

The illustration below is typical of the kind of breakage

that occurs from excessive blank ring.

WORN-OUT FRONT BUSHING(S) OR

RETAINER PIN(S)

Worn-out front bushing(s) will cause the tool to become

misaligned inside the hammer. This misalignment will

cause uneven contact between the piston and tool, thus

causing stress to concentrate on one particular area of

the tool. This can also cause the tool to bind inside the

hammer. Call your dealer for acceptable wear allow-

ances.

Worn-out retainer pin(s) will cause uneven loading on

the pin(s) themselves, causing failure of the tool or re-

tainer pin(s). This will also cause excessive wear to the

front bushing(s).

PROPER CARE OF TOOL BITS

Loading...

Loading...