9.

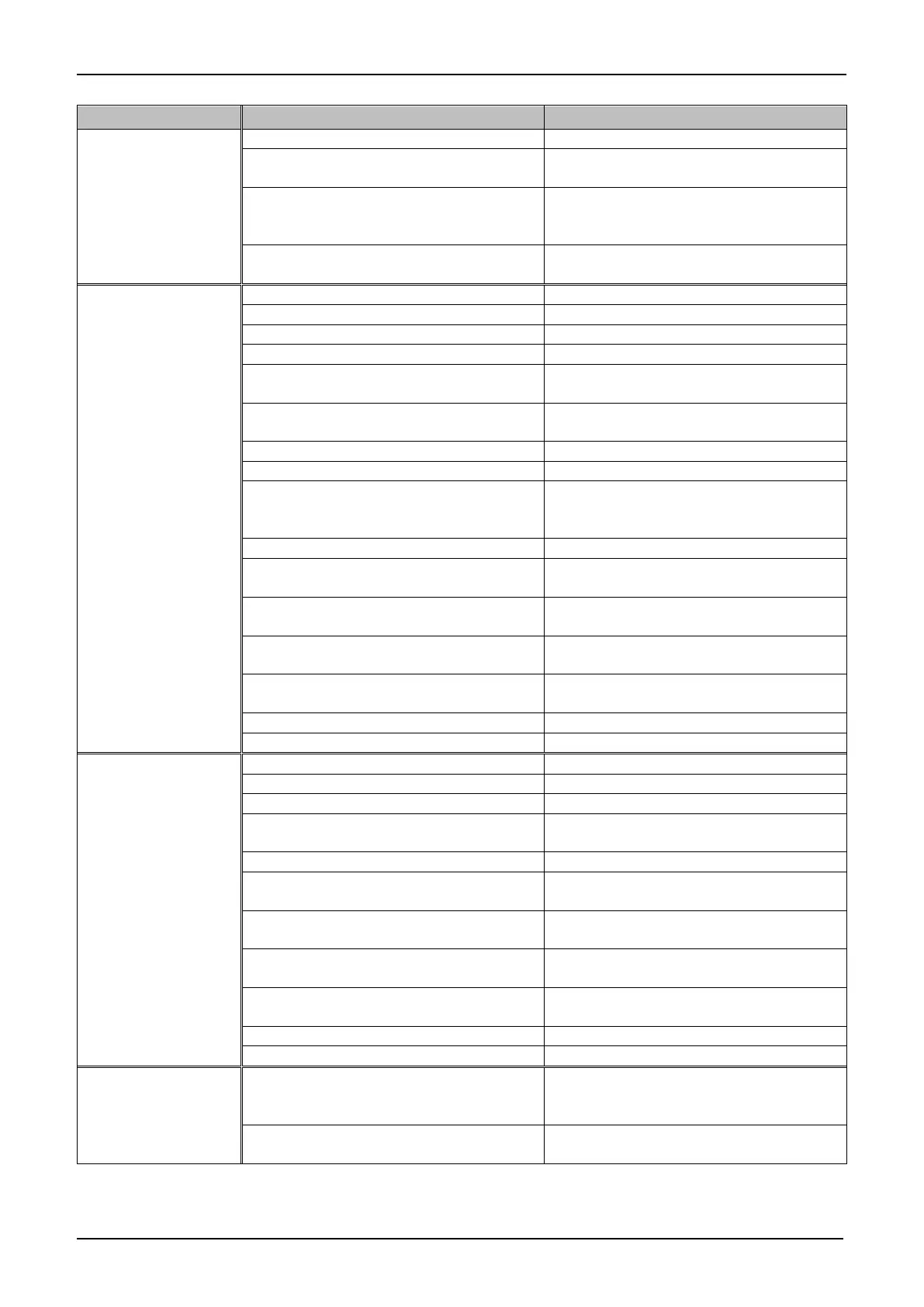

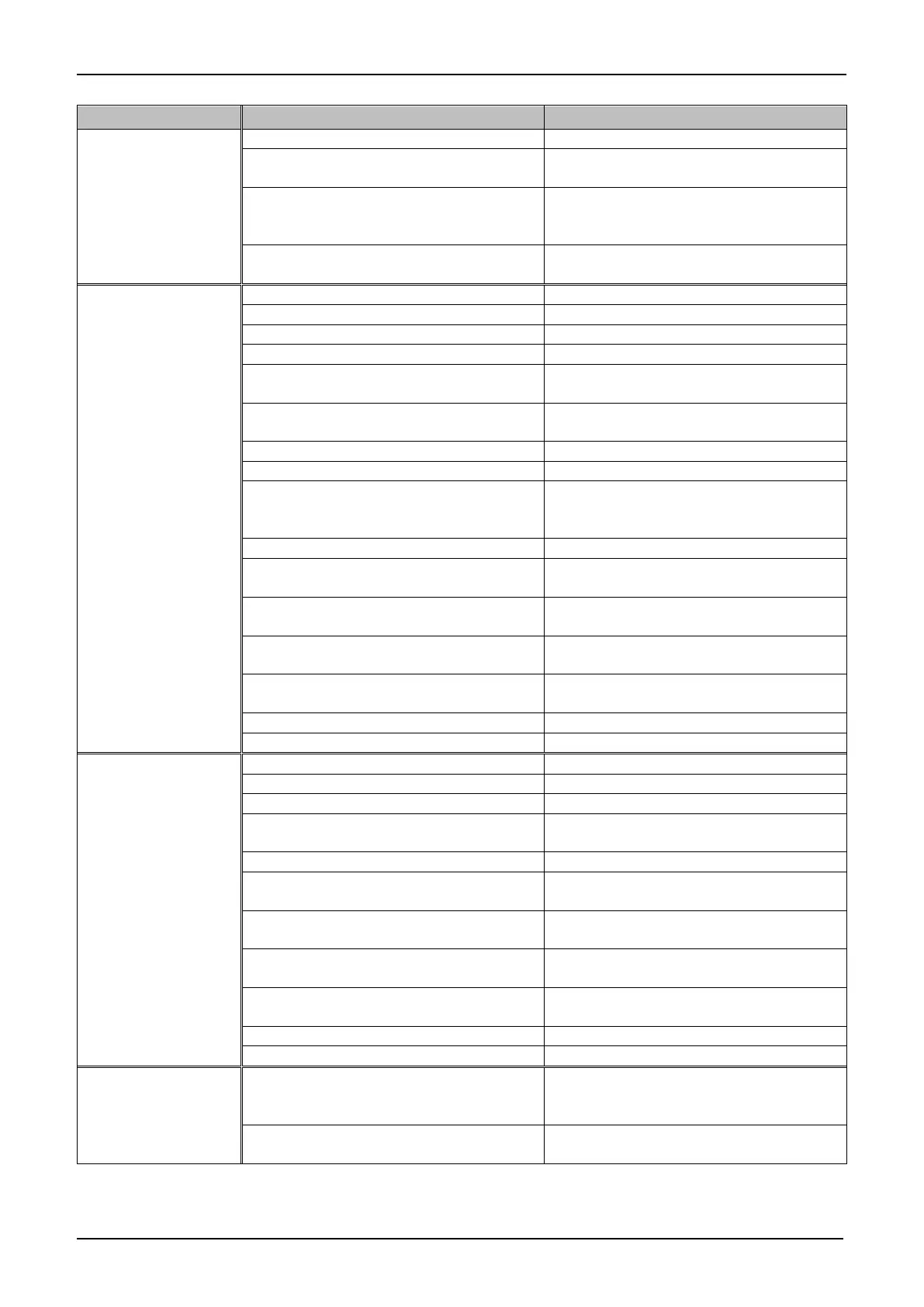

TROUBLESHOOTING (Tool)

Tool does not operate

when trigger is pulled.

Battery is not fully charged.

Battery is not set correctly.

Remove battery and reinsert. Reset tool to

home.

Battery pack has reached operating

temperature limit through continuous use or

defect.

Remove battery and allow it to cool. Mount

battery and reset tool to home. If defect,

replace battery.

Poor electrical connection due to dirty

battery or tool.

Keep the tool and battery clean.

Nut cannot be set up on

nosepiece or mandrel

do not rotate.

Wrong size of nosepiece or mandrel.

Change to appropriate part.

Pull the trigger to switch ON.

Mandrel thread is damaged.

Mandrel offset is too long.

Set the mandrel offset same with nut edge or

longer not more than 0.5mm

Attach the nut on mandrel by push it in with

tool.

To attach the pop nut, follow the procedure

by pressing it against the mandrel by hand.

Contact a local service center.

Rotation part lubrication is inadequate.

Already does not set up action.

Nut set up action in continuous is not

allowed. Do force reverse rotation or pull

trigger for mock stroke.

Change part or contact a local service center

Tool control part is broken.

Reset to factory mode. If not solve, contact a

local service center.

Reset the alarm. If not solve, contact a local

service center.

Take off battery and reinsert. If not solve,

contact a local service center.

Screen counter display is not showing.

Touch TOP icon and get back to counter

display.

Take off battery and reinsert. Switch ON tool.

Nut could not be

fastened. No stroke or

even trigger is pulled,

tool do not operate.

Incorrect setting value of stroke or force

Set the appropriate stroke or force.

Insert the nut, then pull the trigger

Tool or battery temperature is too high.

Cool down the tool or battery before

operating.

Tool control part is broken.

Reset to factory mode. If not solve, contact a

local service center.

Reset the alarm. If not solve, contact a local

service center.

Take off battery and reinsert. If do not solve,

contact a local service center.

Screen counter display is not showing.

Touch TOP icon and get back to counter

display.

Take off battery and reinsert. Switch ON tool.

Nut does not come off

from mandrel.

Excessive fastening stroke damages pop nut

screws

Set the fastening stroke or fastening load to

an appropriate value. When removing, use

forced reversal.

After fastened, tool cannot withdraw from

work.

During withdrawal, gently pull the nut.

Loading...

Loading...