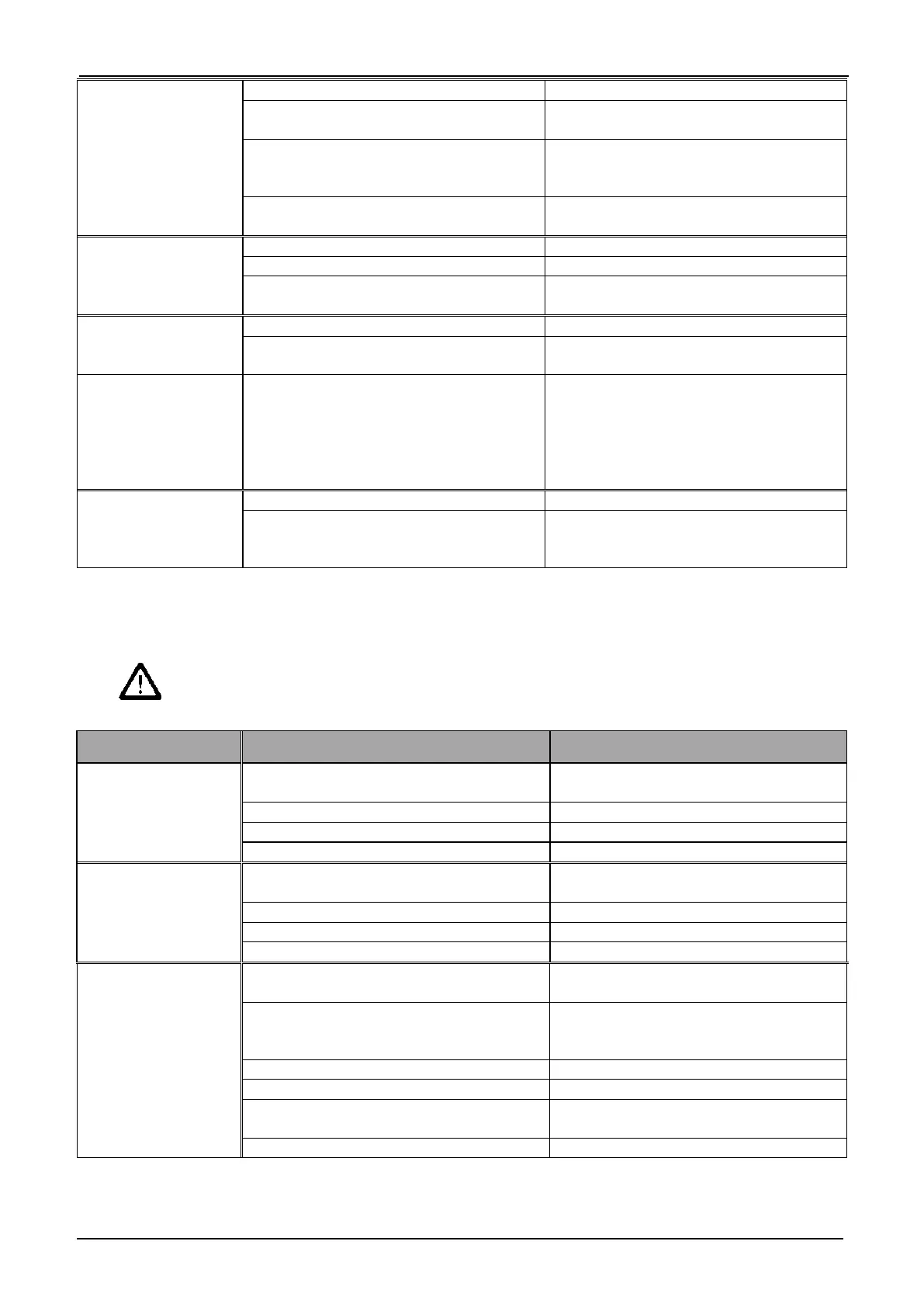

Mandrel is broken or

damaged. Nut is broken

or damaged.

Mandrel lifespan is over.

In stroke control mode, nut is fastened twice

Do not operate with nut that been fasten

once.

Fastened nut stroke and force value are over

than setting.

Set the stroke or force to appropriate value.

Use force reverse to release nut. If mandrel is

damaged change to new.

Nut is fastened in incline position.

Operate by correct way. If mandrel is

damaged change to new.

Not enough fastening

stroke.

Incorrect setting value of stroke or force

Resetting stroke or force appropriate value.

Tool control part is broken.

Reset to factory mode. If not solve, contact a

local service center.

Incorrect setting value of stroke or force

Resetting stroke or force appropriate value.

Tool control part is broken.

Reset to factory mode. If not solve, contact a

local service center.

Appropriate stroke

cannot be adjusted.

Incorrect setting value of stroke or force

If stroke and force mode is ON, switch OFF

force mode, and try again. If the this operate

correctly, force setting is not appropriate. If

cannot adjust, contact a local service center.

Force mode only stroke is no stable compare

to stroke mode.

At full charge, the

number of nuts

fastened is too low than

firstly used.

Nut tools components. Ball screw and thrust

bearing are damaged.

Contact a local service center.

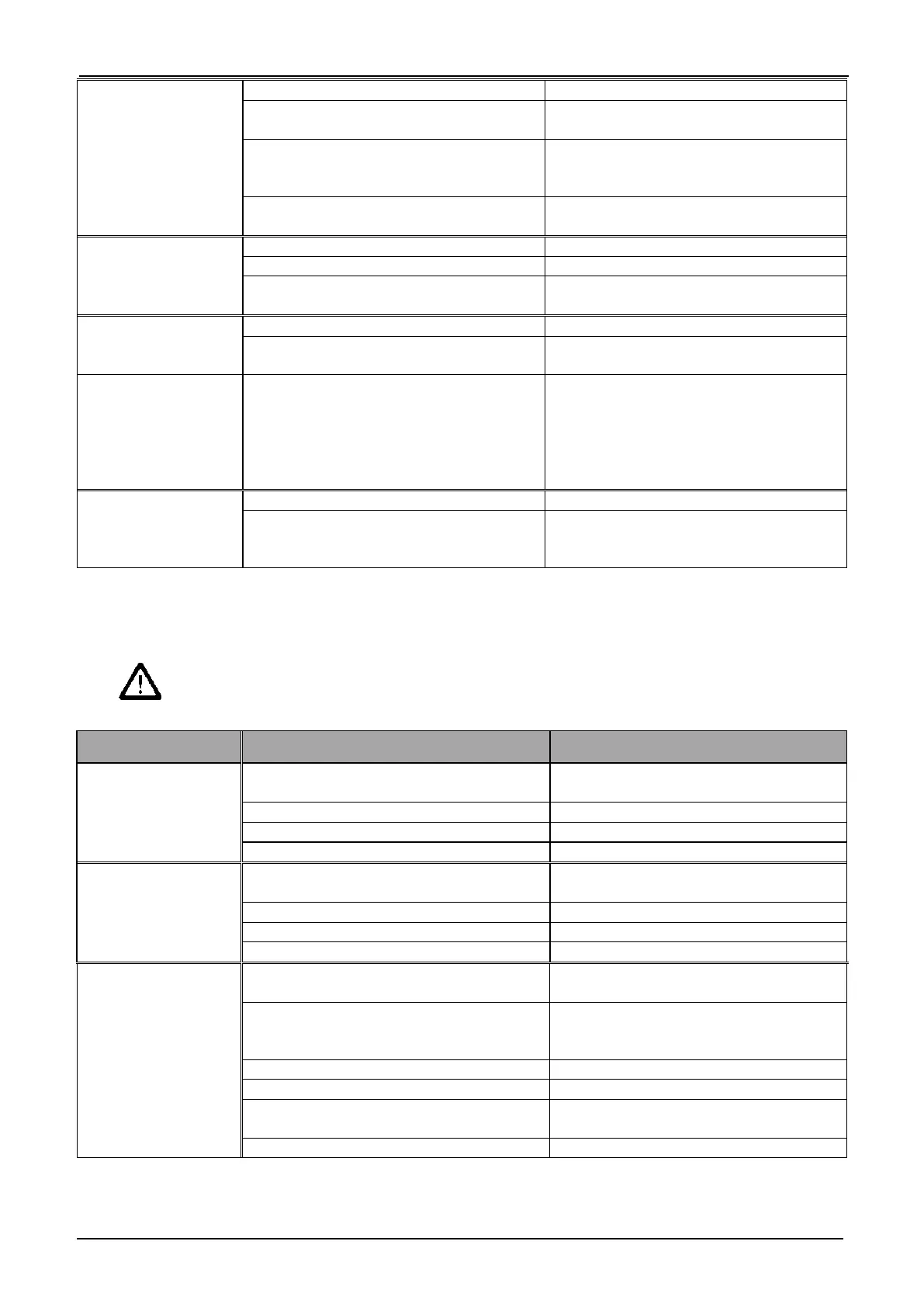

TROUBLESHOOTING (Touch Screen)

WARNING: Read touch screen manual to further understand the troubleshooting of

smart screen.

1. Battery is not fully attached.

Remove battery and re-insert. Reset tool to

home.

2. Battery is not fully charged.

3. Battery is malfunction.

4. Trigger module malfunction.

Contact a local service centre.

Screen freezes at

Stanley Engineered

Fastening Logo

Remove battery and reinsert. Press trigger

to turn ON.

2. Smart screen malfunction.

Contact a local service centre.

3. Trigger module malfunction.

Contact a local service centre.

4. Setting data are broken.

Restore to factory setting.

Tool do not function

when mandrel was

push

1. Screen is not home screen (Counter screen).

Get screen to home scrren. Touch “Back

home” icon to be back home.

2. Screen malfunction, freezing or all white .

Remove battery and reinsert. Press trigger

to turn ON. Or set the tool to default. If not

solve, contact a local service centre.

3. Alarm message is shown with beep sound.

Reset alarm refering to the related pages.

4. Setting data are broken.

Restore to factory setting.

5. Radio communication error.

Restore to factory setting. If not slove,

contact local service centre.

6. If tool is already operating

Continue with fastening or enforced spin off

Loading...

Loading...