5Operation 5

Crane Precautions

1. Movement of the control levers should be

slow and smooth to meter oil flow for safe

operation. Avoid jerky and sudden

movements.

2. The crane controls should be clearly marked

with decals. If these are missing or

illegible,replace immediately. (See Chapter

5: Decals)

3. Lift load slightly off the ground to check the

safety of the cargo. Do not use stability to

determine the safety. Consult the capacity

charts and strictly adhere to them.

4. Be constantly aware of the boom position

when operating the controls.

5. The boom tip should be centered directly

over the load before making the lift to

avoid swinging.

6. Do not drag loads with the crane.

7. Do not attempt to lift fixed loads.

8. Do not load boom in a sideways direction.

9. Know the weight of the rigging and load to

avoid overloading the crane.

10. Do not extend or rotate a load over

anyone.

11. Wear protective gear such as hard hat,

safety glasses, steel-toed boots, and gloves.

12. Maintain a minimum of 5 full wraps of wire

rope on the winch drum at all times.

Hook Precautions

1. Hooks are designed and manufactured to

lift specific loads. The specified rated load of

a hook applies to loads held unifor

mly in

direct tension and does not take into

account shock loads, hook tip loading, side

loading, bending, torsional, or related loads.

2. Do not attempt to lift a load that is larger

than the load rating of the hook.

3. Never use a hook’s yield point as an

indicator of its capacity.

4. Do not use a hook to lift personnel.

5. Know the rated load of the hook in use.

6. Never weld attachments to a finished hook

in field applications. This will alter and

destroy the design properties of the hook

material.

7. Keep fingers, hands, body, and loose

clothing from between the hook and the

load.

8. Avoid shock loading.

9. Inspect the hook regularly for excessive wear

and maintain it in safe operating condition.

Manual Operation

If the remote control malfunctions, follow

these steps to operate the crane manually:

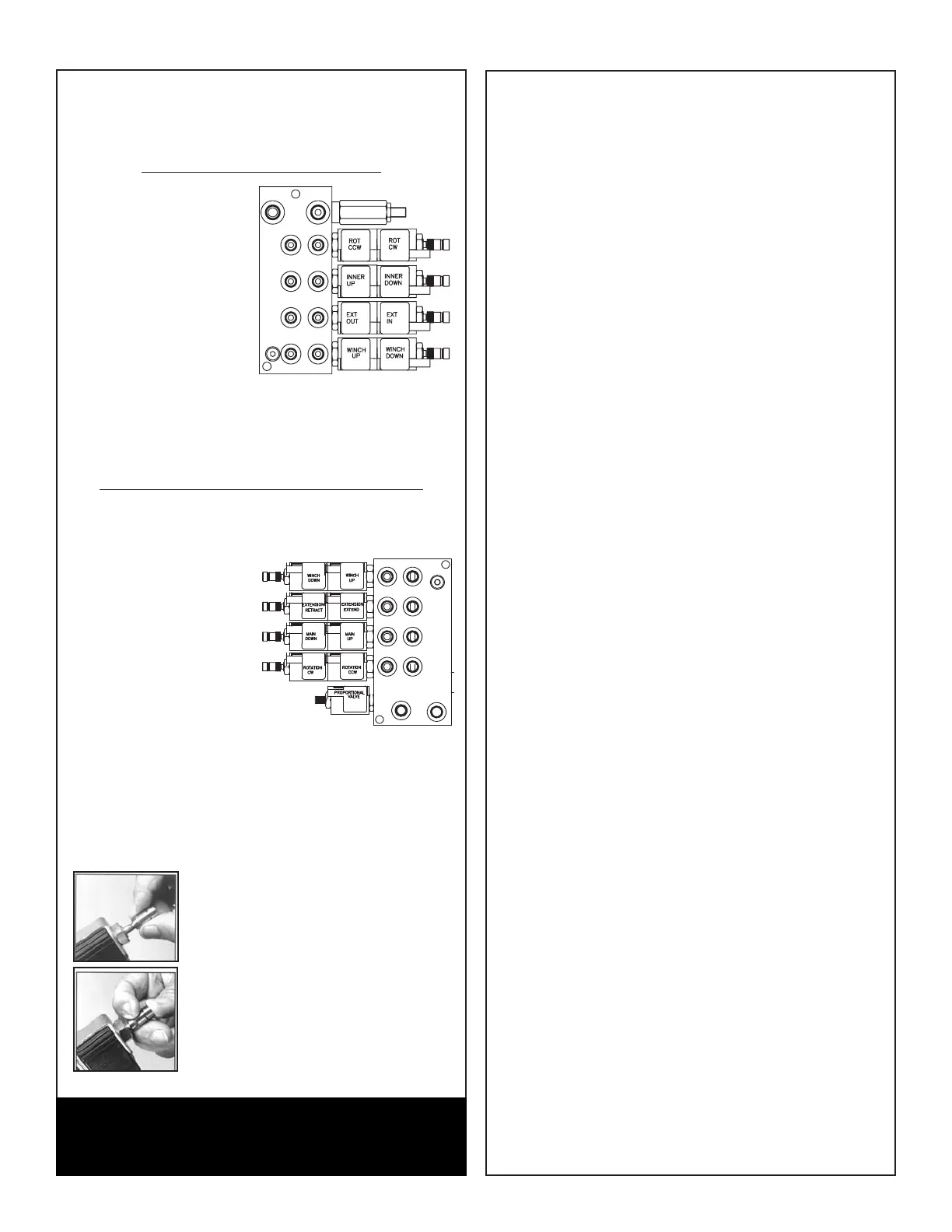

Standard 4420 Manual Override

1. Operate Solenoids.

Slide the knurled

sleeve out and then

push or pull to

operate, as shown

below. Be sure the

sleeve is in the center,

locked, position before

returning to remote

operation. Note: 12V

Power Units must push

the manual override button to allow oil to flow to

the valve banks.

2. Have unit serviced immediately to restore remote

control functionality.

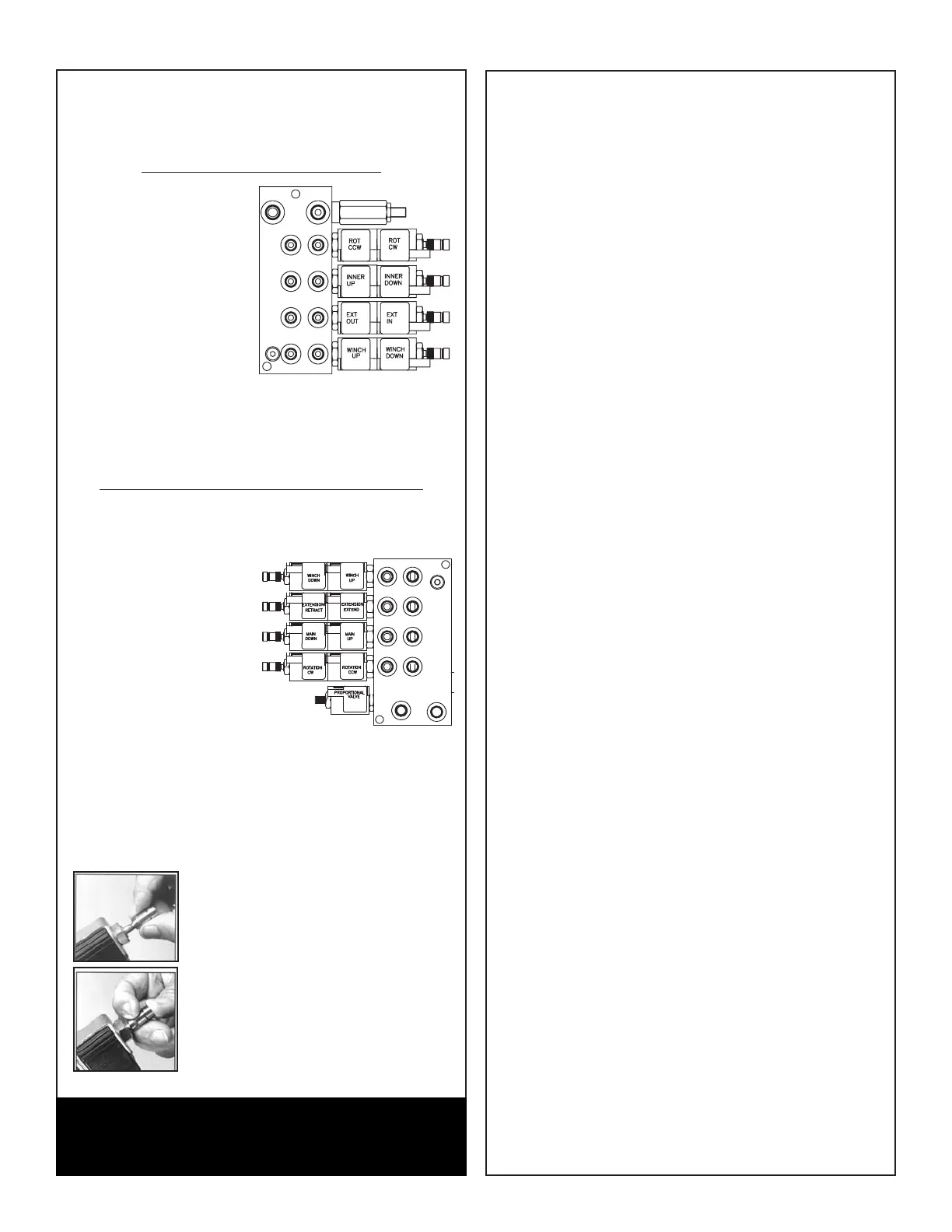

Proportional Version 4420 Manual Override

1. Activate Flow Control.

Turn the override screw on flow control counter-

clockwise.Full adjustment is between three and

fiveturns.

2. Operate Solenoids.

Slide the knurled

sleeveout and then

push or pull to

operate, asshown

below. Be sur

e the

sleeve is in thecenter,

locked, position before

returning toremote

operation.

3. Deactivate flow control. Turn the overridescrew

clockwise until stopped. Fulladjustment is

between 3 and 5 turns.

4. Have unit serviced immediately to restoreremote

control functionality.

Manual Override Pull Function

The knurled sleeve is pulled all the way

out together with the knob to manually

override the pull solenoid function.

Manual Override Push Function

The knurled sleeve should first be pulled

to unlatch the ball latching mechanism

and then, while holding the sleeve

back, the override knob should be

pushed all the way in to override the

push solenoid.

WARNING

Failure to return the valve bank manual overrides to the

neutral position can result in unexpected crane

movement.

Loading...

Loading...