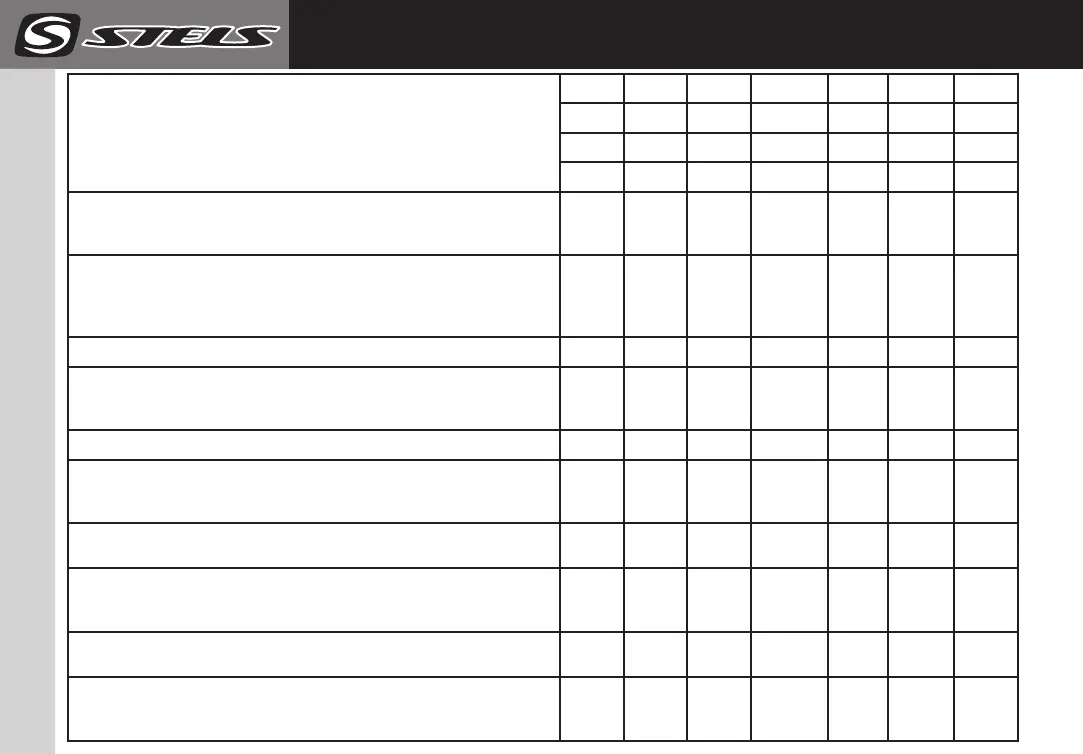

74

650/800/850 GUEPARD

MAINTENANCE

PERFORMED OPERATIONS

OPERATIONAL KM

OPERATING HOURS, HOUR

SERVICE LIFE, MONTHS

М1 М2 М3 М4

М5 М6 М7

300 1200 2400 3600 4800 6000 7200

20 75 150 225 300 375 450

2612 18 24 30 36

4.2. Check the transmission gear lever proper locking and

smoothness. Lubricate the articulated joint (Use multi-purpose

lithium-based grease for lubrication)

** ****

4.3. Check the steering wheel position, the steering system

play, adjust, lubricate, replace worn components, if necessary

(Use multi-purpose lithium-based grease for lubrication)

** ****

5. BRAKES

5.1. Check the braking mechanism operation and the brake

linings wear. Replace the brake linings in case of wear limit

(The lining residual thickness is at least 1 mm)

*******

6. ELECTRIC EQUIPMENT

6.1. Check the electronic engine control unit operation. With

the “Check the Engine” indicator flashing on, detect and

correct the fault. (For EFI system)

* **

6.2. Check the generator operation, replace worn components,

if necessary.

* **

6.3. Check the condition of accumulator battery (batteries),

clean and lubricate the terminals, charge the battery, if necessary

(Use accumulator terminal grease for lubrication).

*******

6.4. Check the lighting devices and alarms, if necessary, to adjust

the light of the headlights

*******

6.5. Check the condition of all electric circuit connections,

replace worn components, if necessary

**

manufacture website : stelsoffroad.com

MAINTENANCE

650/800/850 GUEPARD

75

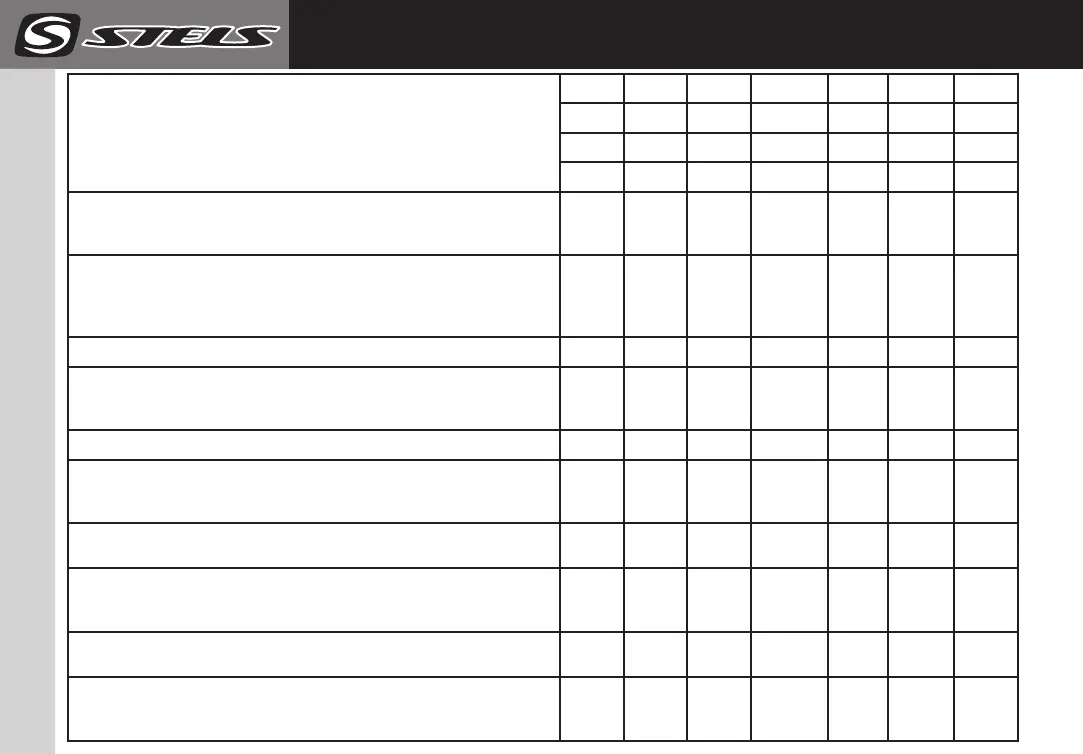

ATTENTION:

In case of a critical driving situation causing the vehicle overload or accidental mechanical effect (hidden

obstacle impact), the driver should stop the vehicle, perform a visual inspection, make sure that there are no

signs of damage or other unwanted consequences, and continue driving upon correcting the detected faults.

NOTE:

The air filter filtering element should be replaced more frequently when operated in humid or dusty

conditions. Brake hydraulic drive maintenance:

- perform regular checks and, if necessary, correct the brake fluid level.

- replace the brake drive hoses in case of fractures and damages.

.

Lubrication recommendations:

- inspect and lubricate timely all the elements in the periods indicated in this table.

- components that are not indicated in the table, should be lubricated during general lubrication period.

.

Recommended lubrication greases:

:

Lubricated assemblies Lubrication Lubrication method

1.

Engine

Engine oils 10W-40 SF

Add the required amount

by a dipstick.

2. Brakes Brake fluid DOT-4

Maintain the required level

Maintain the required level

4. Suspension lever pins Lubricate, if necessary.

5. Steering column Multi-purpose lithium-based greaseLubricate, if necessary.

6. Hub bearing Lubricate, if necessary.

7. Brake drive center guide Lubricate, if necessary.

3.

Front and rear gear boxes Transmission gear oil

SAE75W90 API GL-5

Multi-purpose lithium-based grease

Multi-purpose lithium-based grease

Multi-purpose lithium-based grease

manufacture website : stelsoffroad.com

Loading...

Loading...