3 — Component Identification

19

Operator Manual

AMSCO® 5000 Series

10057344_H

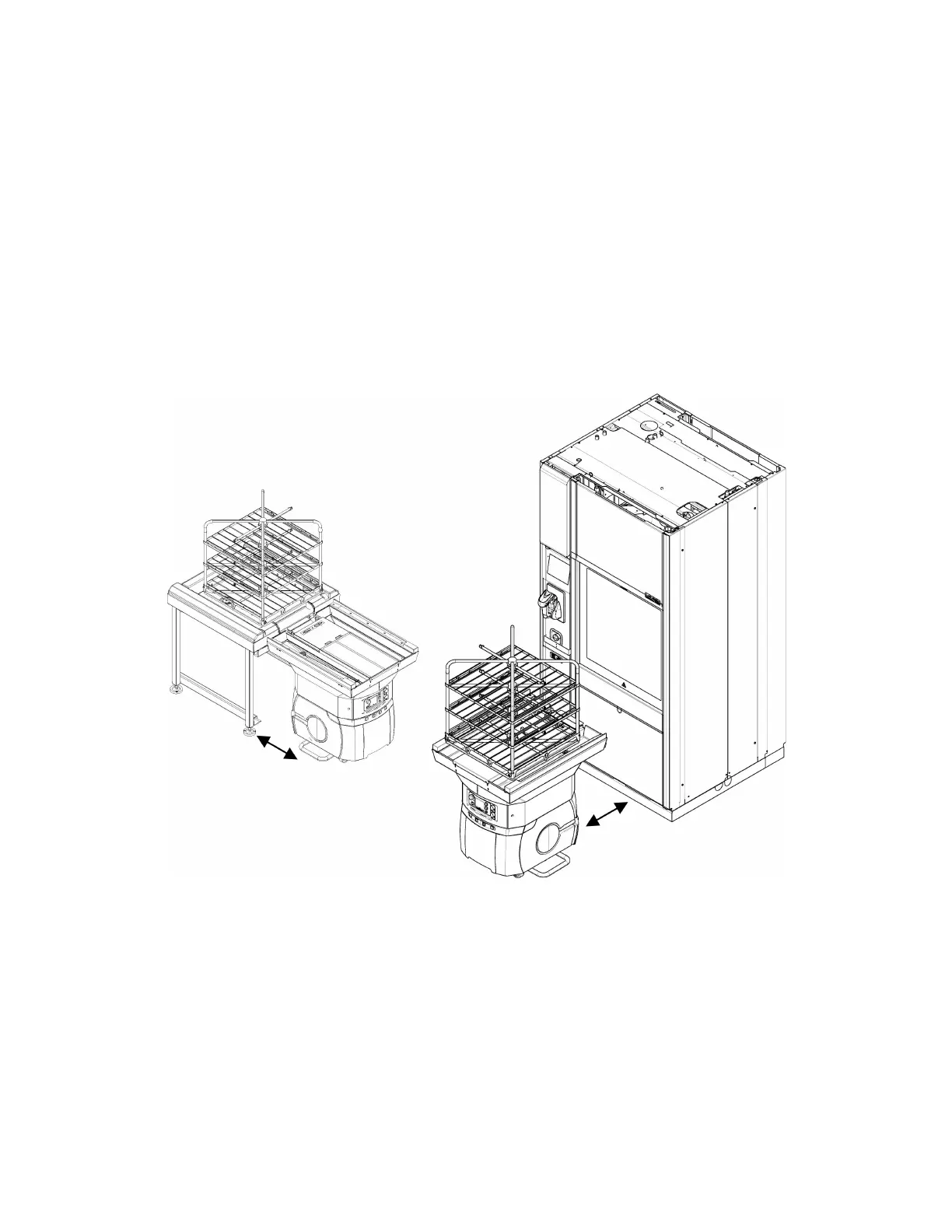

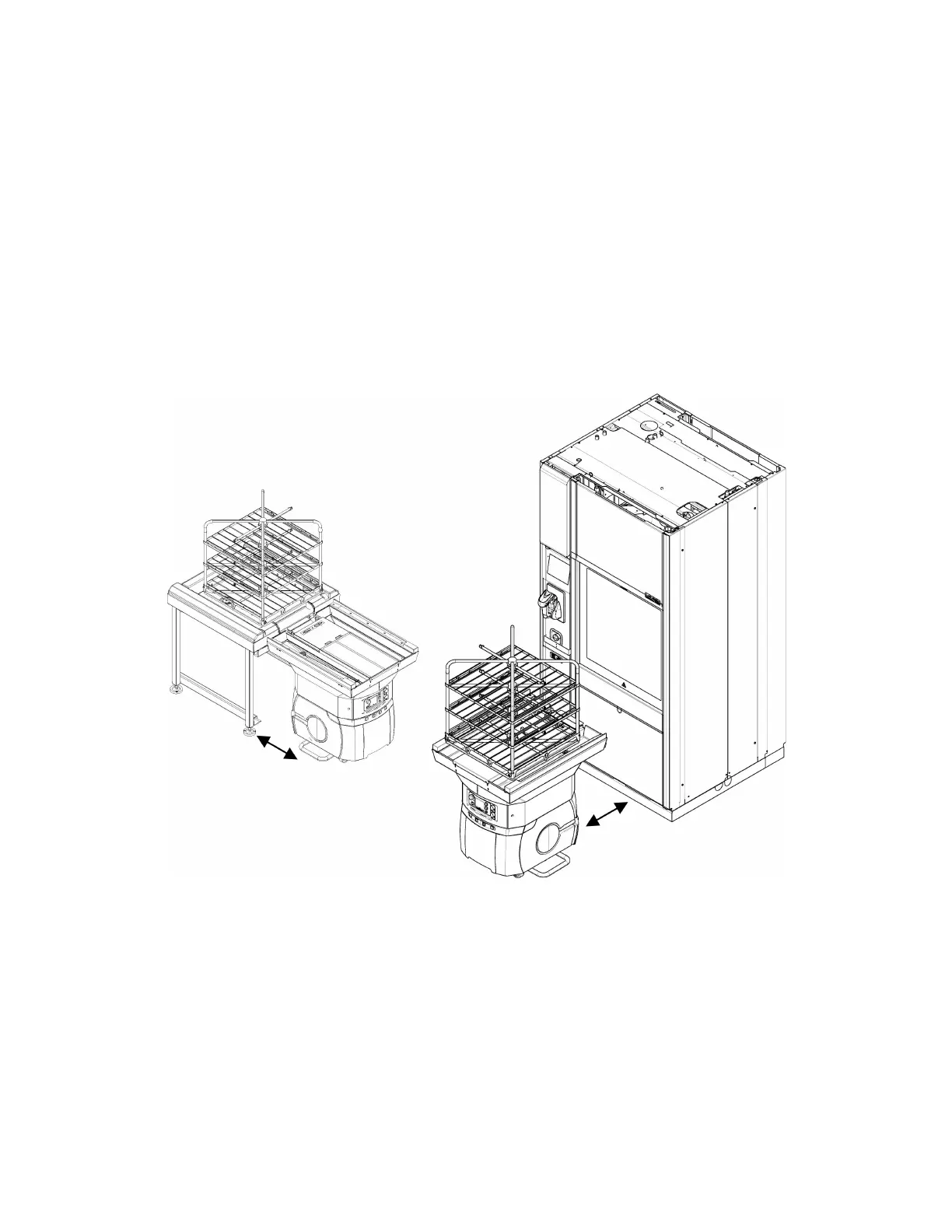

3.6 ATLAS Workflow Automation Vehicle System

See Figure Figure 3-1.

The ATLAS WAV System is an advanced, dynamic system used to automate washer/disinfector loading/unloading

process, washer selection, load prioritization and cycle selection. The System is designed to link multiple, compatible

single-chamber washers into a group that reduces staff movement by expanding the automation path – picking up or

delivering accessories.

This System enables hands-free handling of accessories used in the reprocessing of surgical instruments and other

similar/related items found in healthcare central sterilization services departments.

The ATLAS Workflow Automation Vehicle quietly loads and unloads washer/disinfector accessories and transports

these accessories from or to the ATLAS WAV Rack Workstations.

The accessories validated for use with this equipment can interface with the ATLAS WAV System.

Refer to the ATLAS WAV System Operator Manual for more detailed information about the System and transportation

procedure.

Figure 3-1. ATLAS Workflow Automation Vehicle

3.7 Chemicals and Cycles

Maximizing the efficiency and the life of the washer/disinfector is predicated on the type of water and the cleaning

chemistries used. The corrosive effects of water (deionized, soft and hard water) and contaminants found in water

(such as hardness cations, corrosive anions, metals, etc.) can shorten the useful life of both instrumentation and

equipment. Hard water can result in scale formation as well, which can deposit on both equipment and

instrumentation. It is also important for the cleaning chemistries utilized to have low and controlled foam to maintain

the pressure in the washer/disinfector for adequate impingement and effective rinsing.

Loading...

Loading...