T6800 Rev B Operator Manual Component Identification

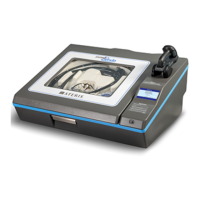

SYSTEM 1 endo Liquid Chemical Sterilant Processing System

4-6

Other control touch pads include:

• The CHANGE VALUES and SAVE VALUES touch pads are used in the

Change Values procedure (see Section 9). Press the CHANGE VALUES

touch pad to access the Change Values routines and move sequentially

through each Change Values selection. Press SAVE VALUES touch pad

to save all changes at any point in the procedure and advance to the end

of the Change Values procedure.

NOTE: Pressing the SAVE VALUES touch pad at any point of the Change

Values procedure will provide a printout of the current settings,

including any changes made.

• The LEFT ARROW (<) and RIGHT ARROW (>) touch pads are pressed

in the Change Values procedure to change “NO” to “YES” (or “YES” to

“NO”), or to move to the beginning (HOME [<]) or end (END [>]) of a line.

• The ENTER touch pad is used to accept data on the display window (if

options are enabled).

• The PAPER FEED touch pad is used to manually advance the printer

paper, such as when a new roll of paper is loaded into the printer. Press

this touch pad once to feed out paper from the roll stored inside the control

panel. Press and hold this touch pad for continuous paper feed.

The control panel also includes touch pads lettered A-Z and numbered

0-9, arranged similar to a telephone keypad. These touch pads are used in

the Change Values procedure for selections and for inputting information,

such as Operator or Procedure ID numbers.

Printer

The printer for the SYSTEM 1 endo

Processor is an impact-type printer with a takeup

motor. The ink-on-paper impact printer records all cycle data on 2-1/4" (57 mm)

wide single-ply paper. Refer to Section 9 for instructions on changing the printer

paper or ink cartridge.

Printouts

Printouts record useful information about each cycle the Processor runs.

Printouts include key cycle data:

• date

• time the cycle was started

• Operator ID number of the person starting the cycle*

• various inputted ID numbers*

• space for manually recording any remarks about the cycle

• starting time of load exposure to the liquid chemical sterilization process

• cycle temperature

• concentration (units of conductivity of use dilution)

• exposure time

• fill time

• inlet temperature

• remaining life of the MaxLife water filter

• Operator ID number of the person unloading the Processor

Loading...

Loading...