www.stiebel-eltron.com WPF | WPF cool | 23

INSTALLATION

Safety

INSTALLATION

8. Safety

Only a qualified contractor should carry out installation, commis-

sioning, maintenance and repair of the appliance.

8.1 General safety instructions

We guarantee trouble-free function and operational reliability only

if original accessories and spare parts intended for the appliance

are used.

8.2 Instructions, standards and regulations

Note

Observe all applicable national and regional regulations

and instructions.

9. Appliance description

9.1 Mode of operation

The heat exchanger on the heat source side (evaporator) extracts

natural heat from the heat source. Any energy extracted is trans-

ferred, together with the energy drawn by the compressor drive,

to the heating water by a heat exchanger on the heating water

side (condenser). Subject to the heat load, the heating water is

heated up to + 65°C.

The electric emergency/booster heater starts if the high pressure

sensor or the hot gas limiter responds during DHW heating. In

addition it covers any residual heat demand, if the heating system

demand exceeds the heat pump output.

9.2 Special features of the WPF...cool

For cooling, the brine is pumped, via a further three-way valve

through a second heat exchanger, where the energy is extracted

from the heating water.

9.3 Standard delivery

The following are delivered with the appliance:

- 1 outside temperature sensor AFS2

- 1 immersion sensor TF6

- 6 push-fit connectors 28) mm

9.4 Accessories

- Brine charging unit WPSF

- Water softener fitting HZEA

- Filter assembly 22 mm (FS-WP 22)

- Filter assembly 28 mm (FS-WP 28)

- Remote control FE 7

- Remote control FEK

10. Preparations

Note

The appliance is designed for internal installation, except

in wet areas.

Never install the appliance directly below or next to

bedrooms.

Protect pipe transitions through walls and ceilings with an-

ti-vibration insulation.

The room in which the appliance is to be installed must meet the

following conditions:

- No risk from frost.

- The room must not be subject to a risk of explosions arising

from dust, gases or vapours.

- When installing the appliance in a boiler room together with

other heating equipment, ensure that the operation of other

heating equipment will not be impaired.

- The volume of the installation room should be at least

13.8m³.

- Load-bearing floor (for the weight of the internal unit, see

chapter “Specification / Data table”).

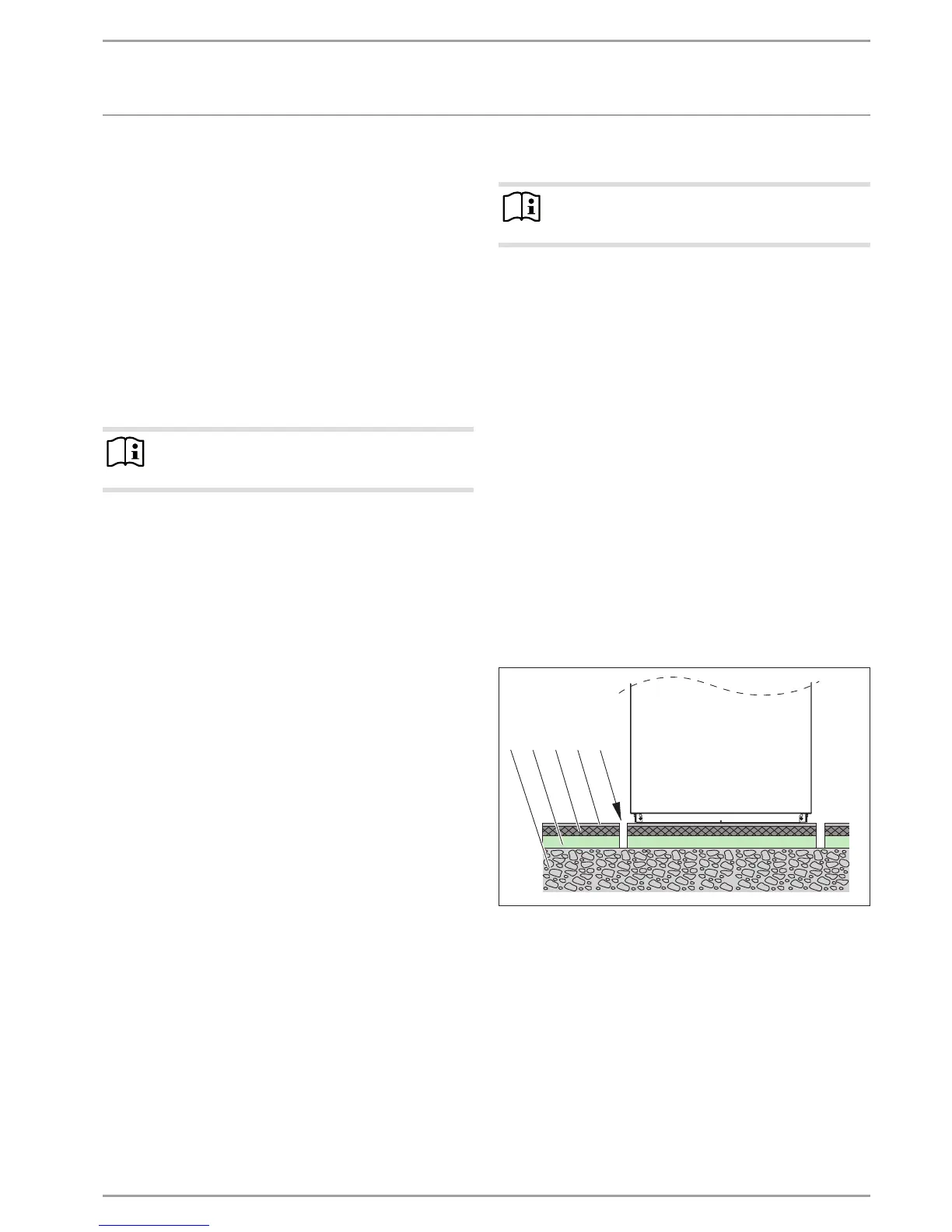

For installation on floating screeds, make provisions for quiet

heat pump operation.

Isolate the mounting surface around the heat pump by re-

cesses. After completing the installation, seal these recesses

with a water-impervious and sound insulating material, such

as silicone for example.

1 2 3 54

26�03�01�1466

1 Concrete base

2 Impact sound insulation

3 Floating screed

4 Floor covering

5 Recess

Loading...

Loading...