www.stiebel-eltron.com WPF | WPF cool | 27

INSTALLATION

Installation

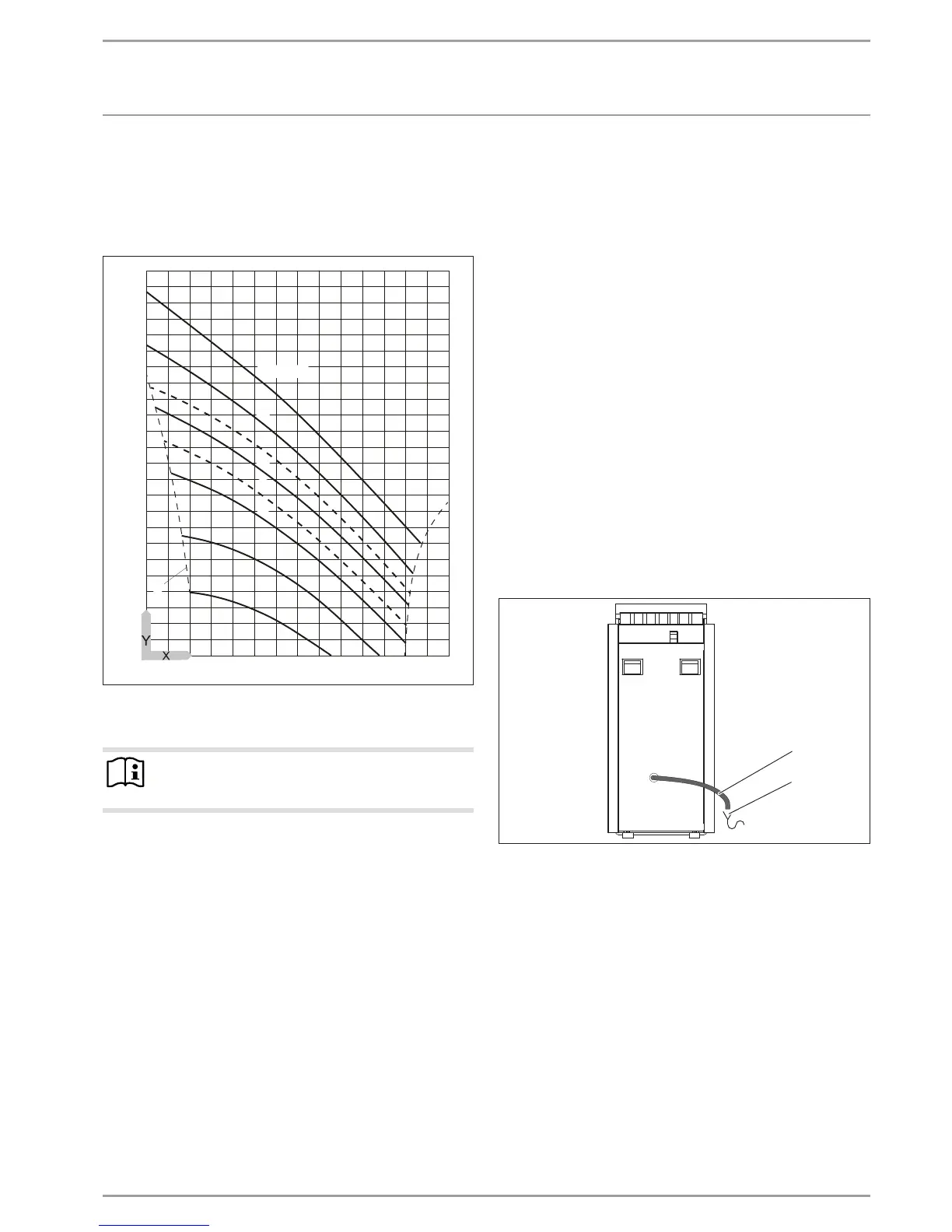

Check the brine concentration:

Determine the density of the ethylene glycol/water mixture,

e.g. with a hydrometer.

Using the actual density and temperature, you can check the actual

concentration in the diagram.

1,10

1,09

1,08

1,07

1,06

1,04

1,03

1,02

1,01

1,00

0,99

0,98

-20 0 20 40 60 80 100

50 Vol.-%

0

1,05

40

33

30

25

20

10

A

26�03�01�1914

X Temperature [°C]

Y Density [g/cm³]

A Frost protection [°C]

Note

The quoted details refer to ethylene glycol (see "Speci-

fication").

Thermally insulate all brine pipes with diffusion-proof material.

The integral pressure expansion vessel is opened and sealed at

the factory. The pre-charge pressure of the expansion vessel on

the brine side should be checked and adjusted, if required. For

this, the system fill pressure must be higher than the pre-charge

pressure plus max. brine pump pressure differential.

For geothermal probes, the expansion vessel is suitable for a fill

volume of up to 600l.

11.5 Heating water connection

The heating system to which the heat pump is connected must be

installed by a qualified contractor in accordance with the water

installation diagrams that are part of the technical guides.

Thoroughly flush the pipework before connecting the heat

pump. Foreign bodies, such as rust, sand and sealant, can

impair the operational reliability of the heat pump. We rec-

ommend installing our filter assembly in the heating return

(see chapter "Accessories").

To facilitate an easy connection to the heating system, the appli-

ance is supplied with plug-in connectors (see chapter "Fitting the

push-fit connector").

Connect the heating system to the "heating flow" and "heat-

ing return" connections. Check for tightness.

Ensure the correct connection of the heating flow and return.

When sizing the heating circuit, observe the maximum avail-

able external pressure differential (see chapter "Specification

/ Data table").

Provide thermal insulation in accordance with applicable

regulations.

At the factory, the pressure expansion vessel on the heating side

is sealed in the open position at the cap valve.

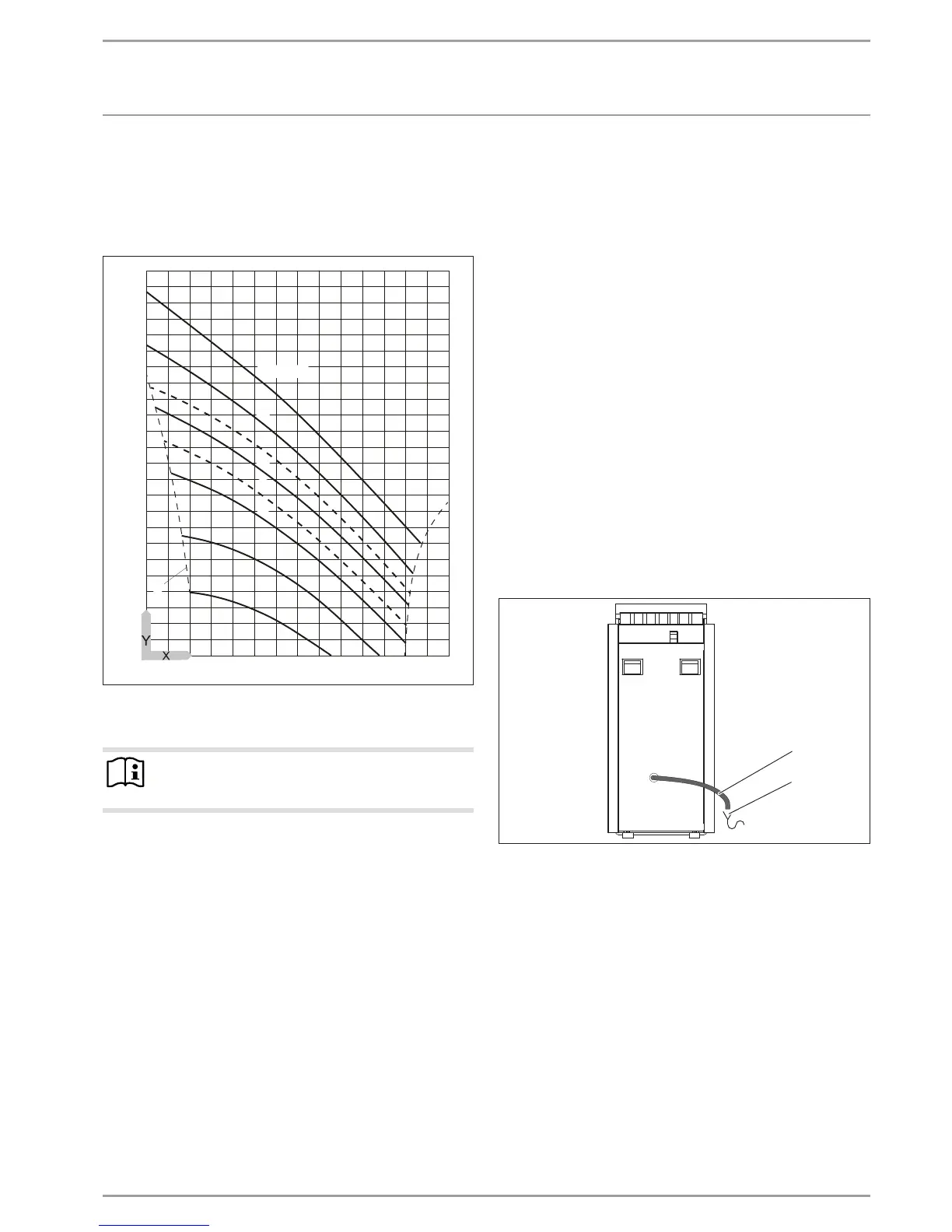

Safety valve

26�03�01�1855

1

2

1 Drain

2 Discharge outlet

Size the discharge outlet so that water can drain off unim-

peded when the safety valve is fully opened.

Ensure that the safety valve drain is open to the outside.

Install the safety valve drain with a constant fall to the dis-

charge outlet. When installing the drain, never kink the pipe.

Loading...

Loading...