34 |WPF | WPF cool www.stiebel-eltron.com

INSTALLATION

Commissioning

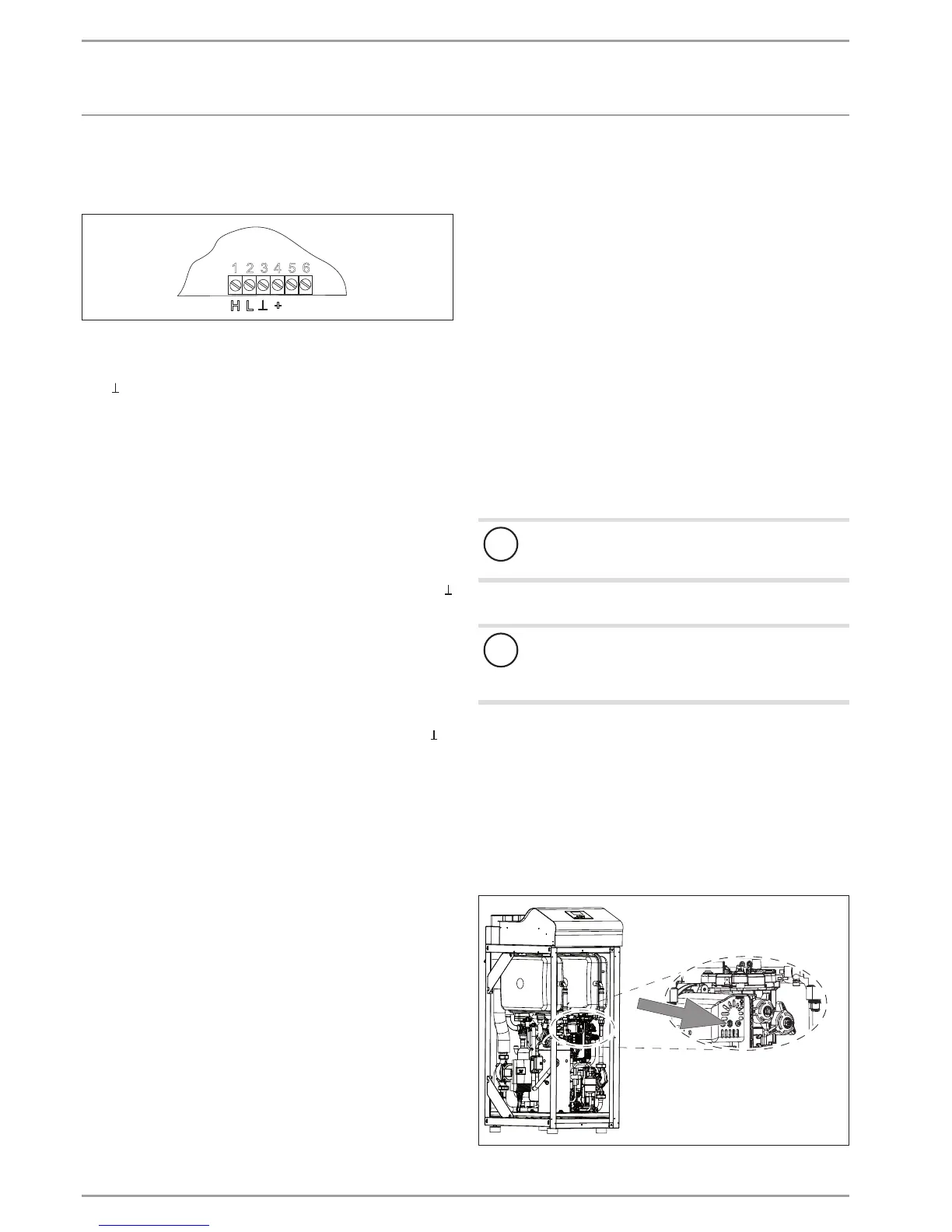

12.6 Remote control FEK

Connection array FEK

1

2

3

4

5

6

H

L

+

26�03�01�0094

The FEK remote control enables you to change the set room tem-

perature for heating circuit 1 or heating circuit 2 by ± 5 °C as well

as the operating mode. Connect the remote control to terminals

H, L, and + to terminal block X2 of the appliance.

Also observe the FEK operating instructions.

12.7 Uponor DEM WP module

When an Uponor DEM WP module is connected, the heating curve

is dynamically optimised for the heat demand of individual rooms.

This involves modifying the preset heating curve by up to 50%

of its initial value.

The Uponor DEM WP module is connected as an alternative to an

FE7 remote control. Operation with both devices is not possible.

Connect the Uponor DEM WP module to terminals Fernb.1 and

to terminal block X2 of the appliance.

Also observe the Uponor DEM WP module operating

instructions.

12.8 Internet Service Gateway ISG

The Internet Service Gateway ISG lets you operate the heat pump

in your local home network and via the internet when on the go.

Connect the Internet-Service-Gateway to terminals H, L, and to

terminal block X2 of the appliance.

The ISG is not supplied with power via the heat pump.

Also observe the ISG operating instructions.

13. Commissioning

Only qualified contractors may carry out the adjustments on the

heat pump manager commissioning report, commission the ap-

pliance and instruct the owner in its use.

Commissioning should be carried out in accordance with these

operating and installation instructions. Our customer service can

assist with commissioning, which is a chargeable service.

Where this appliance is intended for commercial use, the rules of

the relevant Health & Safety at Work Act may be applicable for

commissioning. For further details, check your local authorising

body.

13.1 Checks before commissioning

Before commissioning check the points detailed below.

13.1.1 Heating system

- Have you filled the heating system to the correct pressure?

- Have you closed the quick-action air vent valve of the multi

function assembly (MFG) again after venting?

!

Material losses

Observe the maximum system temperature in underfloor

heating systems.

13.1.2 Heat source

!

Material losses

Never use the heat pump to dry the screed by means of

the underfloor heating system (see chapter „Menu struc-

ture/ Menu PROGRAMS/ HEAT-UP PROGRAM“).

13.1.3 Temperature sensor

- Have you correctly positioned and connected the outside

temperature sensor and the return temperature sensor (in

conjunction with a buffer cylinder)?

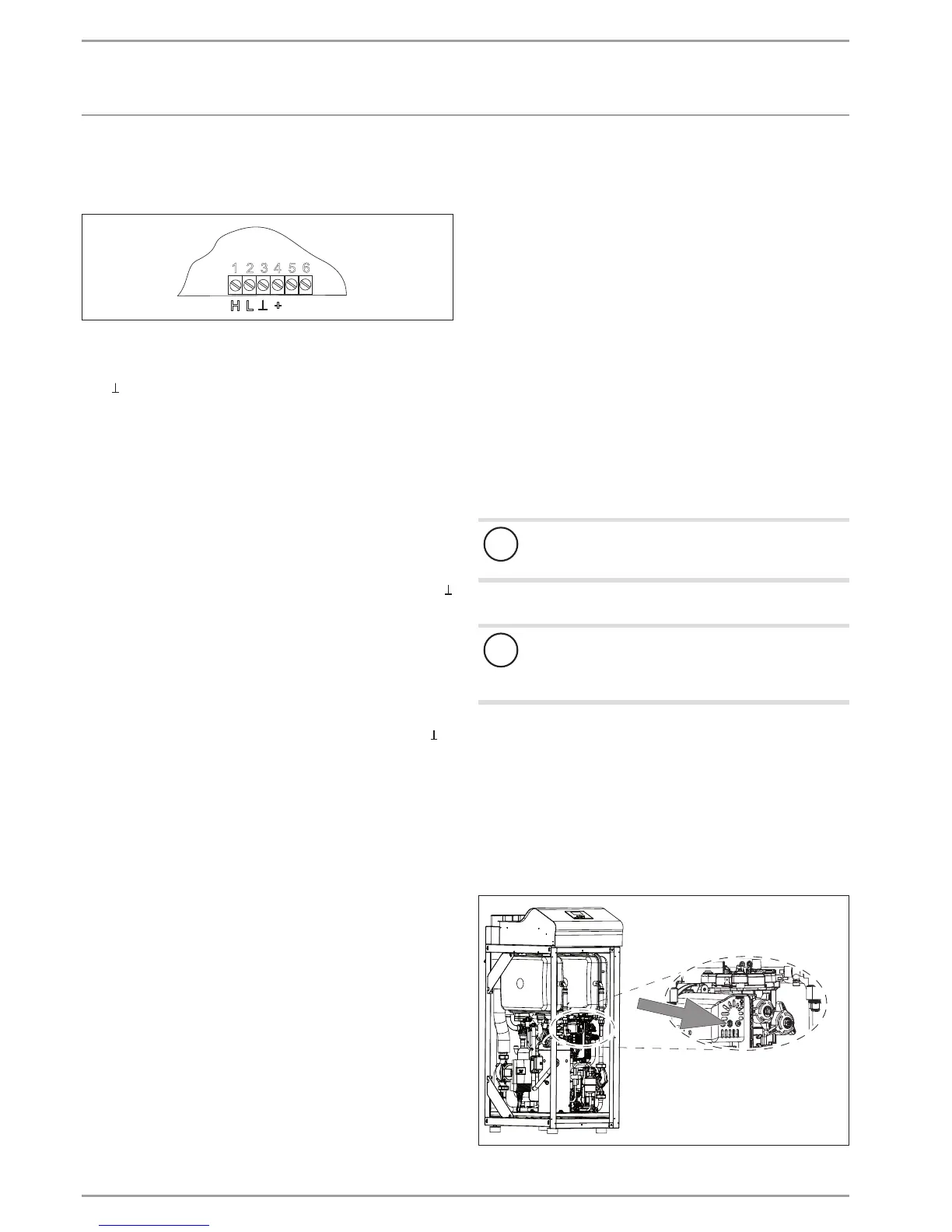

13.1.4 High limit safety cut-out

At ambient temperatures below -15 °C the high limit safety cut-out

of the multi function assembly may respond.

Check if the high limit safety cut-out has responded.

D0000036150

1 Electric emergency/booster heater

2 High limit safety cut-out reset button

Loading...

Loading...