10 | WPF 20/27/40/52/66 WWW.STIEBEL-ELTRON.COM

Mixing ratio

The brine concentration varies when using a ground collector or

a geothermal probe as a heat source.

The mixing ratio can be found in the table below.

Ethylene glycol Water

Geothermal probe 25% 75%

Geothermal collector 33% 67%

After filling the system with brine and prior to commissioning.

open the fill & drain valve until brine runs out of it. No water must

remain in the pipe run to the fill & drain valve.

10.3.3 Check the brine concentration:

f Determine the density of the ethylene glycol/water mixture,

e.g. with a hydrometer.

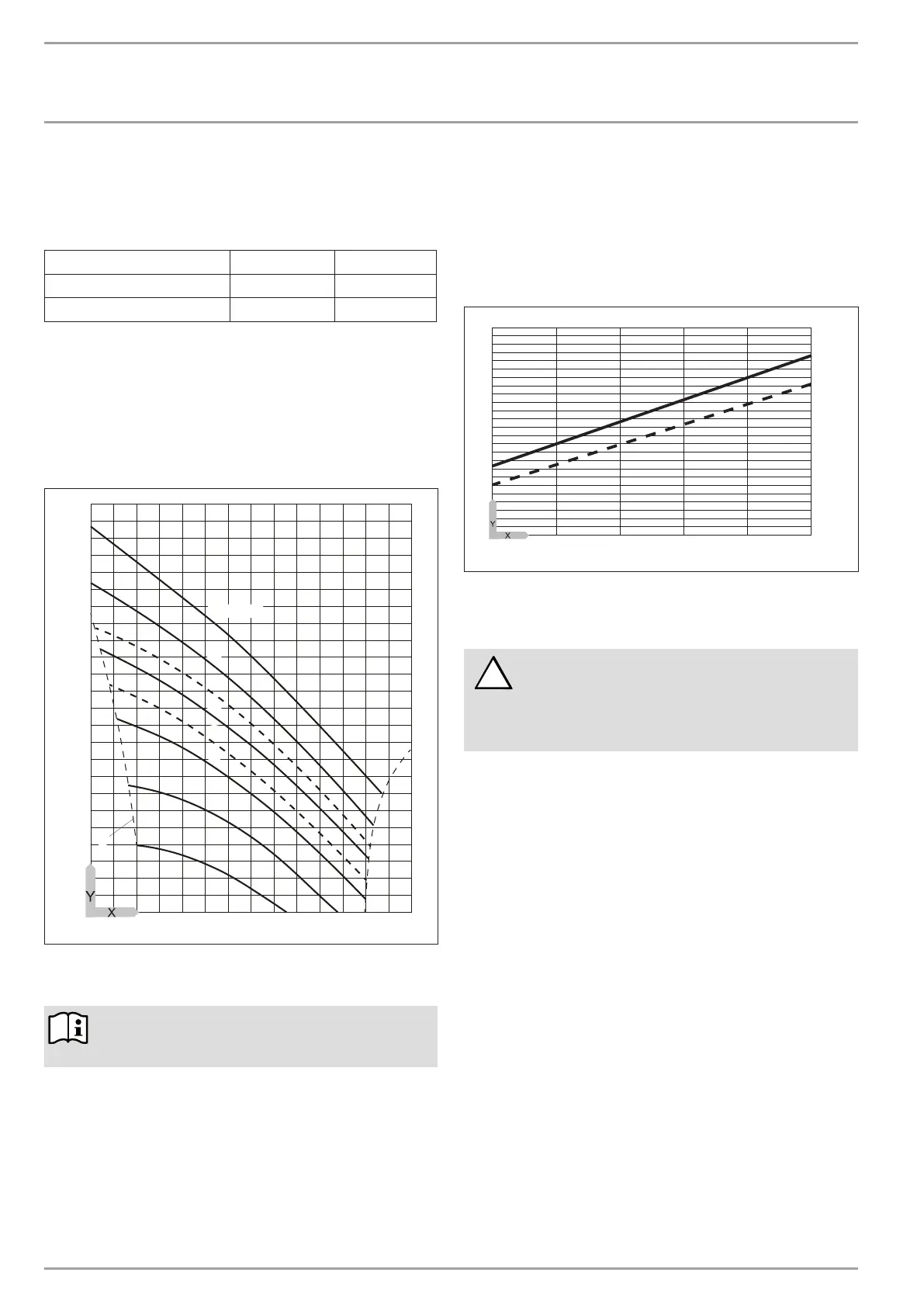

Using the actual density and temperature, you can check the actual

concentration in the diagram.

1,10

1,09

1,08

1,07

1,06

1,04

1,03

1,02

1,01

1,00

0,99

0,98

-20 0 20 40 60 80 100

50 Vol.-%

0

1,05

40

33

30

25

20

10

A

26�03�01�1914

X Temperature [°C]

Y Density [g/cm³]

A Frost protection [°C]

Note

The quoted details refer to ethylene glycol (see

"Specification").

10.3.4 Checking the flow rate (during heat pump

commissioning)

Check the flow and return temperatures of the heat source. For

this. determine the temperature differential by measuring the

temperature under the thermal insulation on both flow and return

pipes of the heat pump.

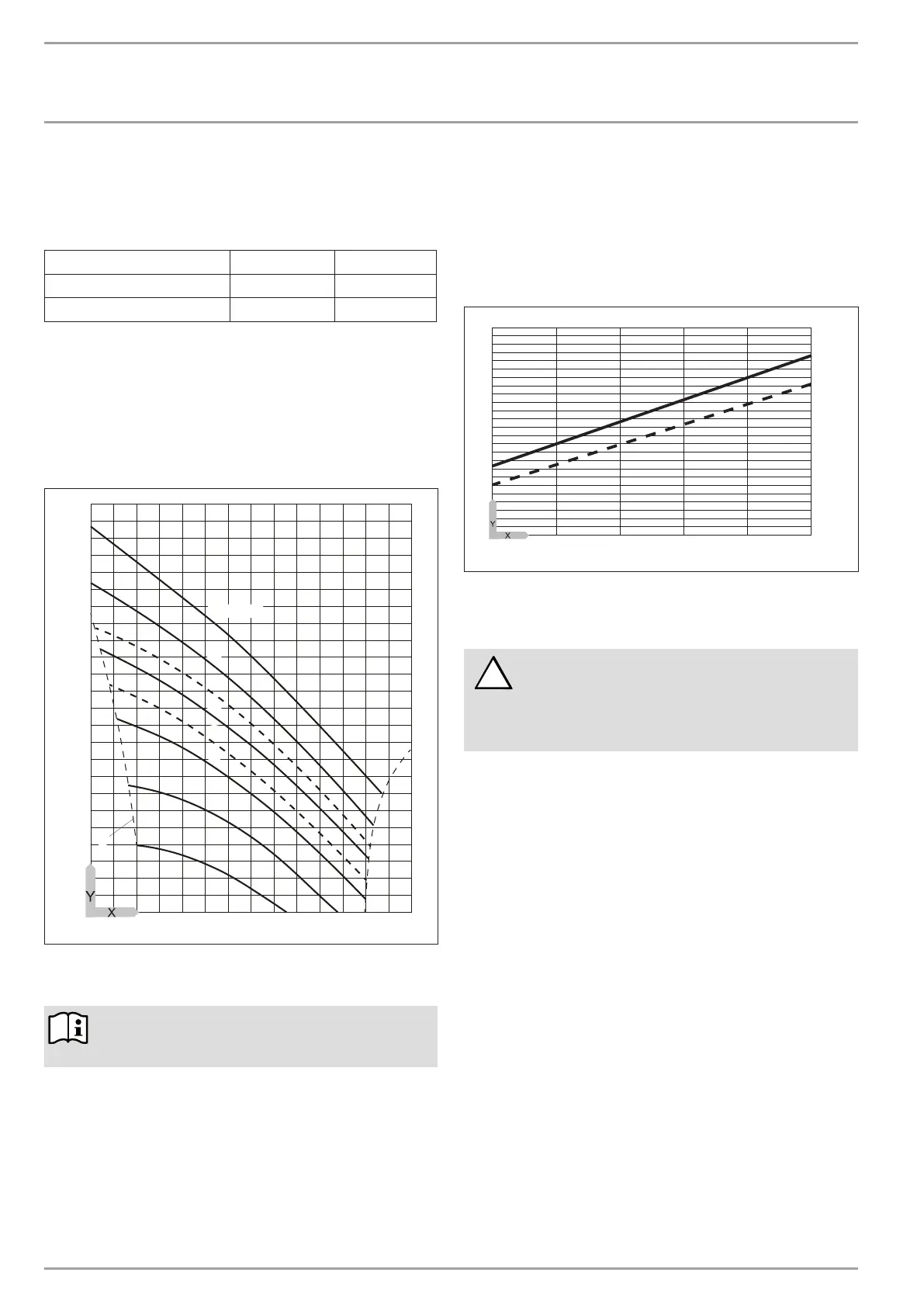

The diagram shows the temperature spread at the nominal flow

rate.

6

1

2

5

4

3

2

1

-5 0 5 10 15 20

84�03�01�0017

Y Temperature differential

X Source inlet temperature

1 Brine = heating flow 35 °C

2 Brine = heating flow 50 °C

!

Risk of damage!

At the WPM II. set parameter source in the commissioning

list to "Ethylene glycol". otherwise the frost stat would

stop the heat pump at temperatures below 7 °C. The

source inlet temperature can be checked on the display

of the WPM II under the Info Temp. system parameter.

10.4 Installation of the heat consumer system

The layout of the connection material on the heating side has to

be done according to the evaporator and condensator materials

(Technical Datas) to avoide corrosion.

Implement the heat consumer system (heating circuit) in

accordance with current technical rules. For safety equipment in

heating systems. consult the DIN EN 12828.

Ensure the correct connection of the heating flow and return.

Protect the heating water lines against frost and moisture (only

in case of external installation). Protect flow and return lines

in external installations with an adequate amount of thermal

insulation against frost and by routing them inside a conduit

against moisture

.

Maintain the required insulation thickness in accordance with the

Heating System Order [or local regulations].

The integral frost protection control (inside the heat pump). that

automatically starts the circulation pump in the heat pump circuit

at + 8 °C and thereby safeguards circulation in all water-bearing

components. offers additional frost protection. The heat pump is

started automatically no later than when the temperature inside

the buffer cylinder drops below + 5 °C.

Prior to connecting the heat pump. check the heating system for

leaks. flush it thoroughly. fill and carefully vent it.

INSTALLATION

INSTALLATION

Loading...

Loading...