WWW.STIEBEL-ELTRON.COM WPF 20/27/40/52/66 | 9

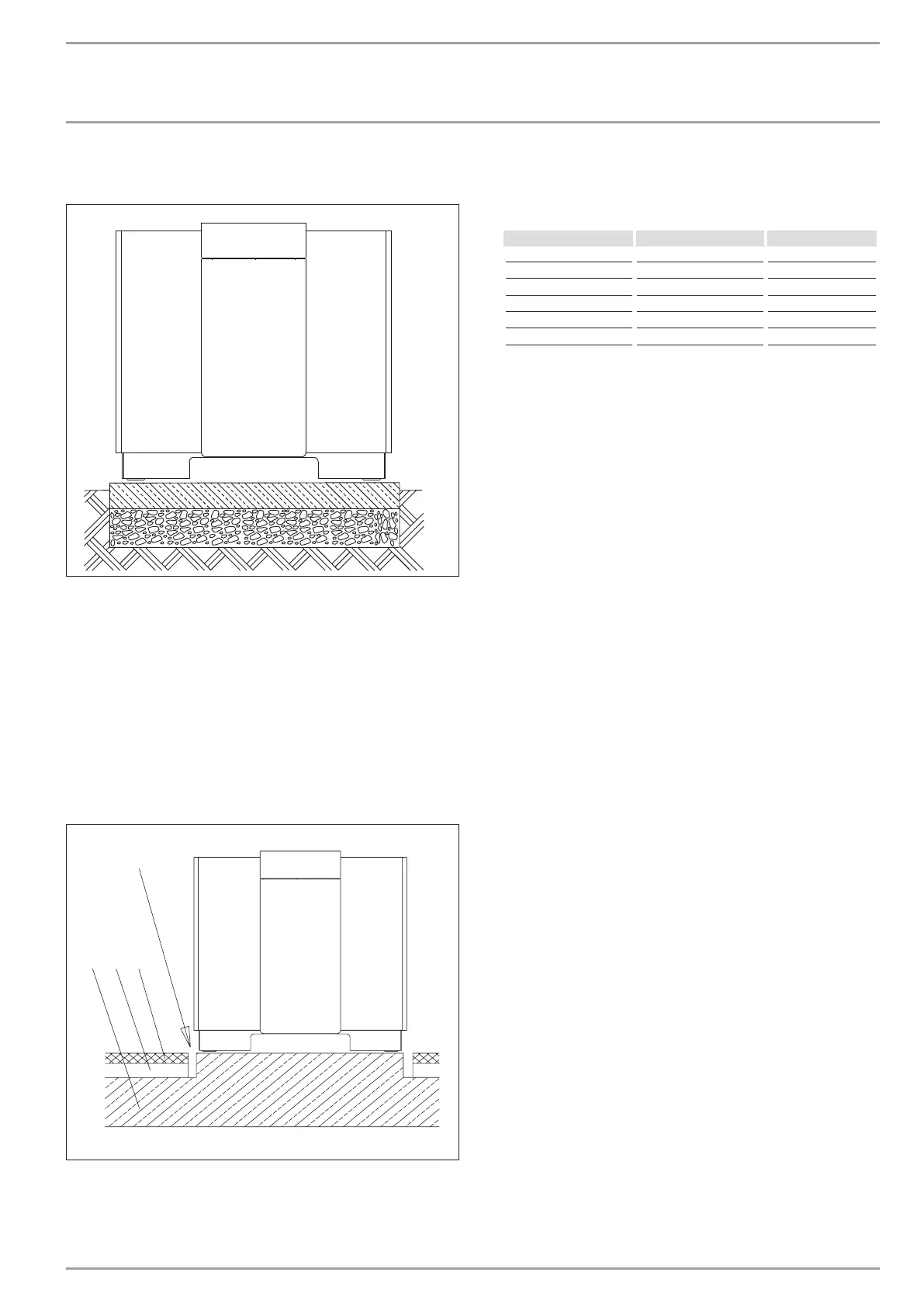

10.2.2 External installation

We recommend foundations as base for the device.

26�03�01�0803

Route all supply lines inside a conduit that is free from frost

(protective pipe).

Protect the connection area at the back panel against all weather

and solar influences.

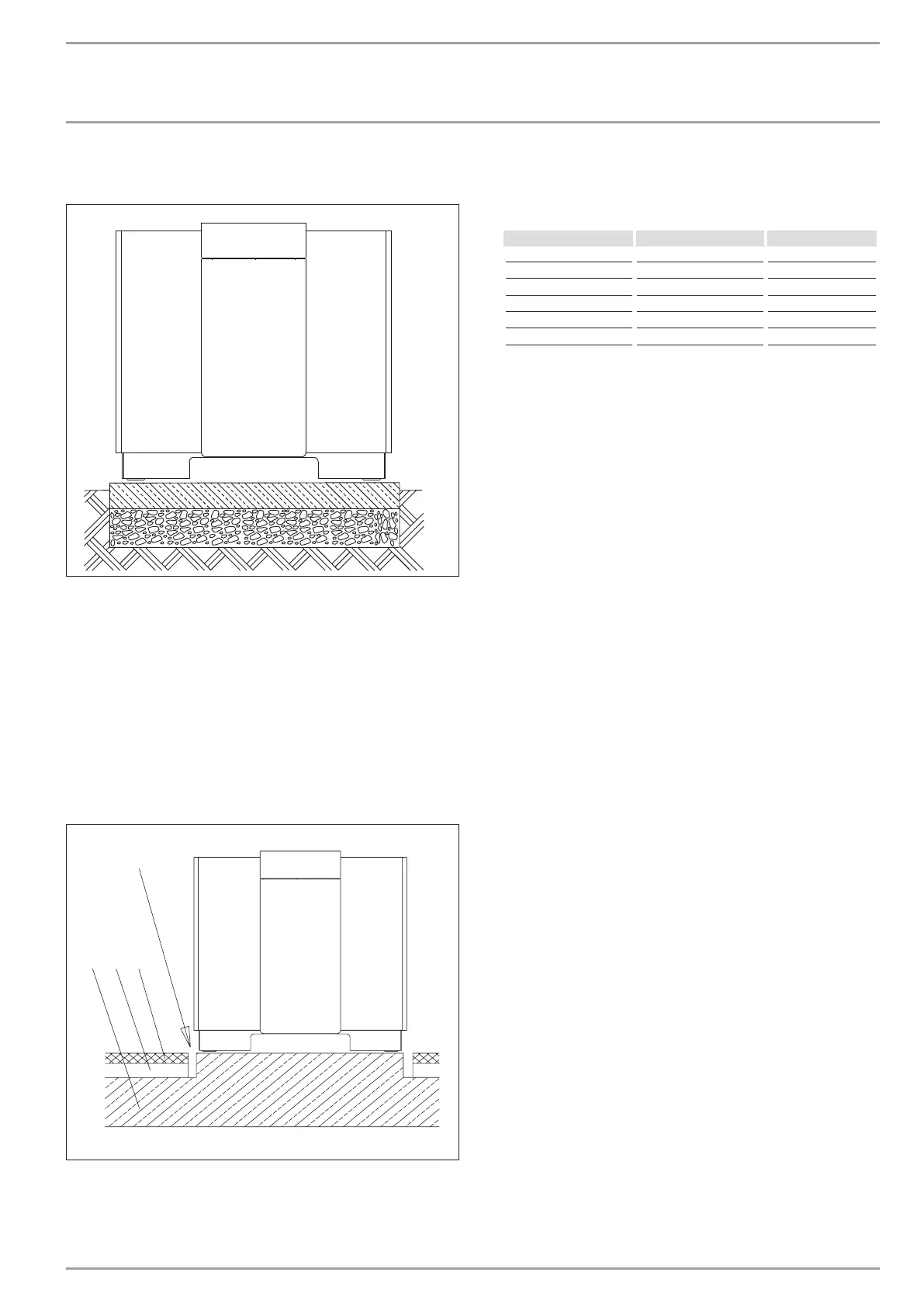

10.2.3 Internal installation

The room where the WPF is to be installed must meet the following

conditions:

- Load-bearing floor. For the weight of the WPF. see

"Specification".

- For a quiet heat pump operation on floating screeds. recess

the screed and the anti-vibration insulation around the

installation location

of the heat pump.

4

2

1

C26�03�01�0802

3

1 Concrete ceiling

2 Impact sound insulation

3 Floating screed

4 Recess

- The room must not be subject to a risk of explosions arising

from dust. gases or vapours. Never allow the floor area

and the volume of the installation room to be less than the

minimum values listed in the table.

Typ Volume Floor area

WPF 20 14 m³ 5 m²

WPF 27 | WPF 27 HT 16 m³ 7 m²

WPF 35 23 m³ 9 m²

WPF 40 23 m³ 9 m²

WPF 52 28 m³ 11 m²

WPF 66 33 m³ 13 m²

- When installing the WPF in a boiler room together with

other heating equipment ensure. that the operation of other

heating equipment will not be impaired.

10.2.4 Sound emission.

Never install the heat pump immediately below or adjacent to

bedrooms. Insulate pipes through walls and ceilings against

structure-borne noise transmission.

10.3 Installation of the heat pump system

The layout of the connection material on the soruce side has to

be done according to the evaporator and condensator materials

(Technical Datas) to avoide corrosion.

Design the heat source system for the brine/water heat pump in

accordance with Stiebel Eltron technical guides.

Permitted brine:

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 231109

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 161696

10.3.1 Circulation pump and required flow rate

Use a circulation pump with compound-filled windings to supply

the brine. to prevent an earth short circuit through condensation

in the electrical part of the pump (cold water version).

Size the circulation pump in accordance with the system-specific

conditions. i.e. nominal flow rate and pressure drop must be taken

into consideration (see "Specification").

An adequate flow rate must be safeguarded at every possible

brine temperature. i.e.:

Size the nominal flow rate at brine temperature 0 °C with a

tolerance of + 10 %.

10.3.2 Connection and filling with brine

Prior to connecting the heat pump. check the heat source circuit

for possible leaks. and flush thoroughly.

Calculate the volume of the heat source circuit. You can obtain the

brine volume inside the heat pump from the "Specification" table.

The overall volume equals that of the required amount of brine

that should be mixed from undiluted ethylene glycol and water.

The chloride content of the water must not exceed 300 ppm.

INSTALLATION

INSTALLATION

Loading...

Loading...