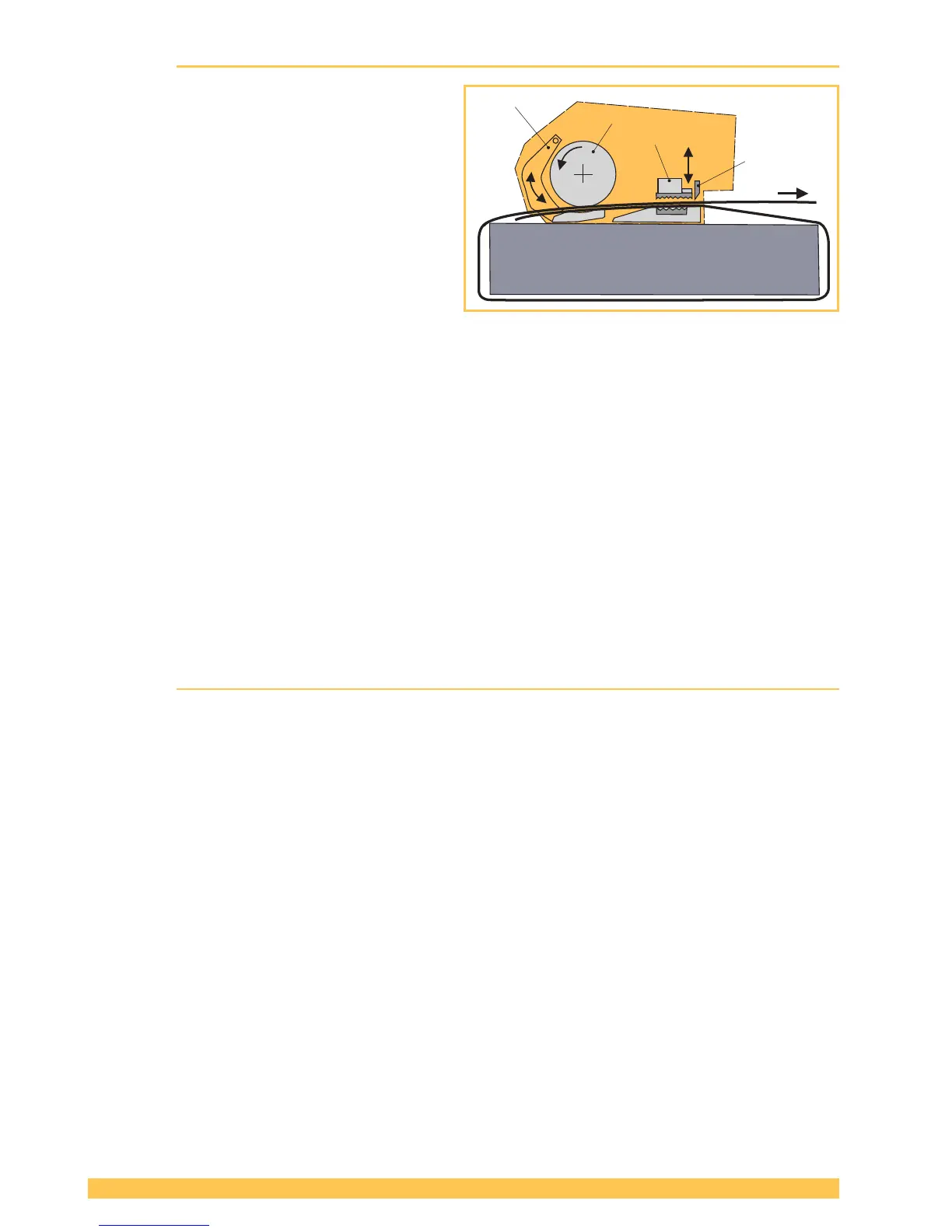

3.2 Function

● The rocker lever is used to open the tension-

ing device so that the straps can be inserted.

● The straps are clamped between the tooth

plate on the rocker (1) and the tension wheel

(2).

● The strap is tensioned by the tension wheel

(2) rotating in a counter-clockwise direction.

● The straps are welded in the welding device

(3) using the friction welding process.

● The upper strap is cut off by the knife (4).

● You can choose between three operating

modes: (Section 4.2)

● Semi-automatic (standard/factory setting)

● Fully automatic

● Manual

● You can also choose between two tension

ranges: (Section 4.3/4.4)

● Standard tension for PET straps

● Soft tension for PP straps (Tension wheel

starts slowly. Prevents excessive dirt and

grime build up in tool.)

● The welding time can be set.

(Section 4.5)

● The tools can be operated with different strap

widths (Section 7):

● STB 71: 9–10 mm, 12–13 mm (

3

/

8

″,

1

/

2

″)

● STB 73: 12–13 mm, 15–16 mm (

1

/

2

″,

5

/

8

″)

STB 75: 15–16 mm, 18–19 mm (

5

/

8

″,

3

/

4

″)

3.3 Scope of delivery

For strapping tool STB 71 / STB 73: ● Battery 18 V/2.0 Ah Li-Ion Part no 2187.011

● Battery charger GAL 1880 CV EU Part no 2188.020

or for USA version: ● Battery 18 V/2.0 Ah (US) BAT612 Part no 2187.012

● Battery charger (US) BC1880 Part no 2188.021

or for Japan version: ● Battery charger GAL 1880 CV (JP) Part no 2188.022

or for Australia version: ● Battery charger GAL 1880 CV(AUS) Part no 2188.023

Tool kit consisting of: ● Wire brush

● Screwdriver Torx T20

● Offset screwdriver

Part no 1821.901.004

Part no 1821.901.010

Part no 1821.901.007

Loading...

Loading...