3. Ensure electrical supply is compatible with the details that are stated on the pump

rating plate. (The wrong voltage or frequency can be dangerous and may damage

the pump.)

4. Priming

(330, 500, 600, Kennet, Loddon and Thame Range)

a) Flooded suction installation

The pump must be primed (filled with liquid) before starting. Turn on liquid

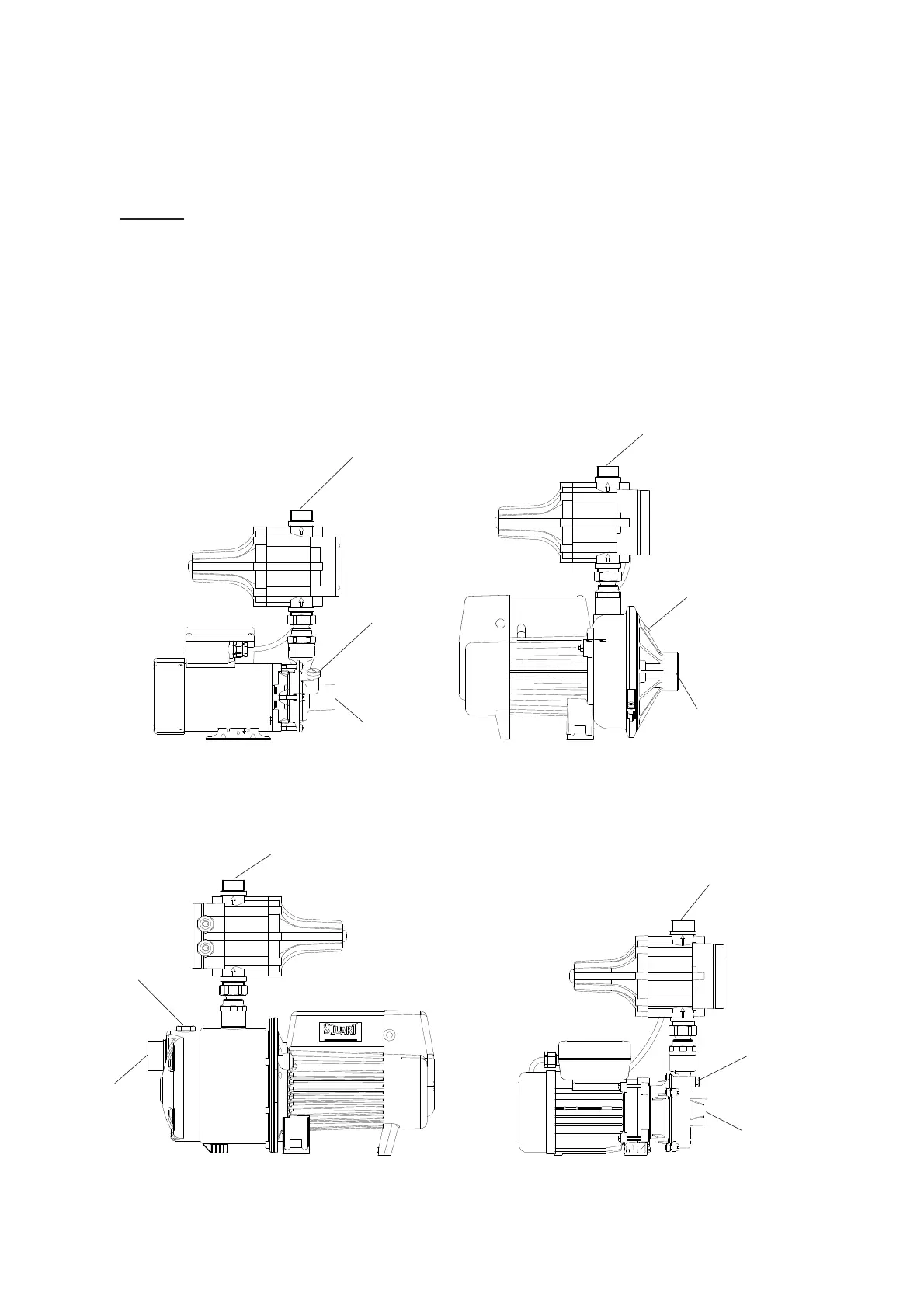

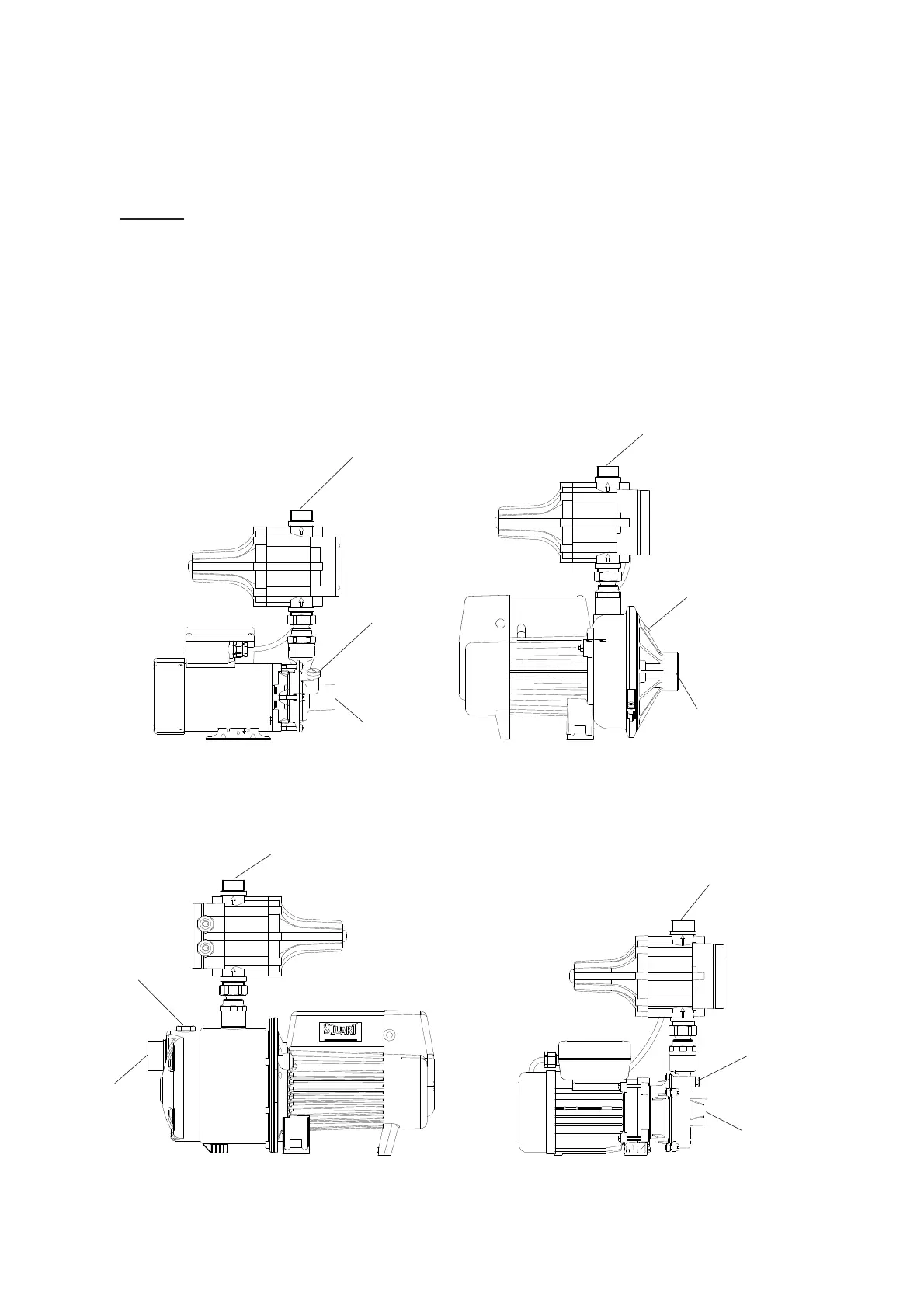

supply, prime and vent the pump by unscrewing the priming plug (Figs. 21-25)

slowly until all air escapes and liquid emerges. Re-tighten plug.

b) Suction lift installation

A footvalve and strainer must be fitted to the end of the inlet pipework. Prime the

suction pipework by filling before connecting to the pump. Prime the pump by

filling via the priming plug (Figs. 21-25).

-21-

Loading...

Loading...