60 EN/09.2019/G41 © STULZ GmbH – all rights reserved

cybercool 2 screw original insTrUcTions

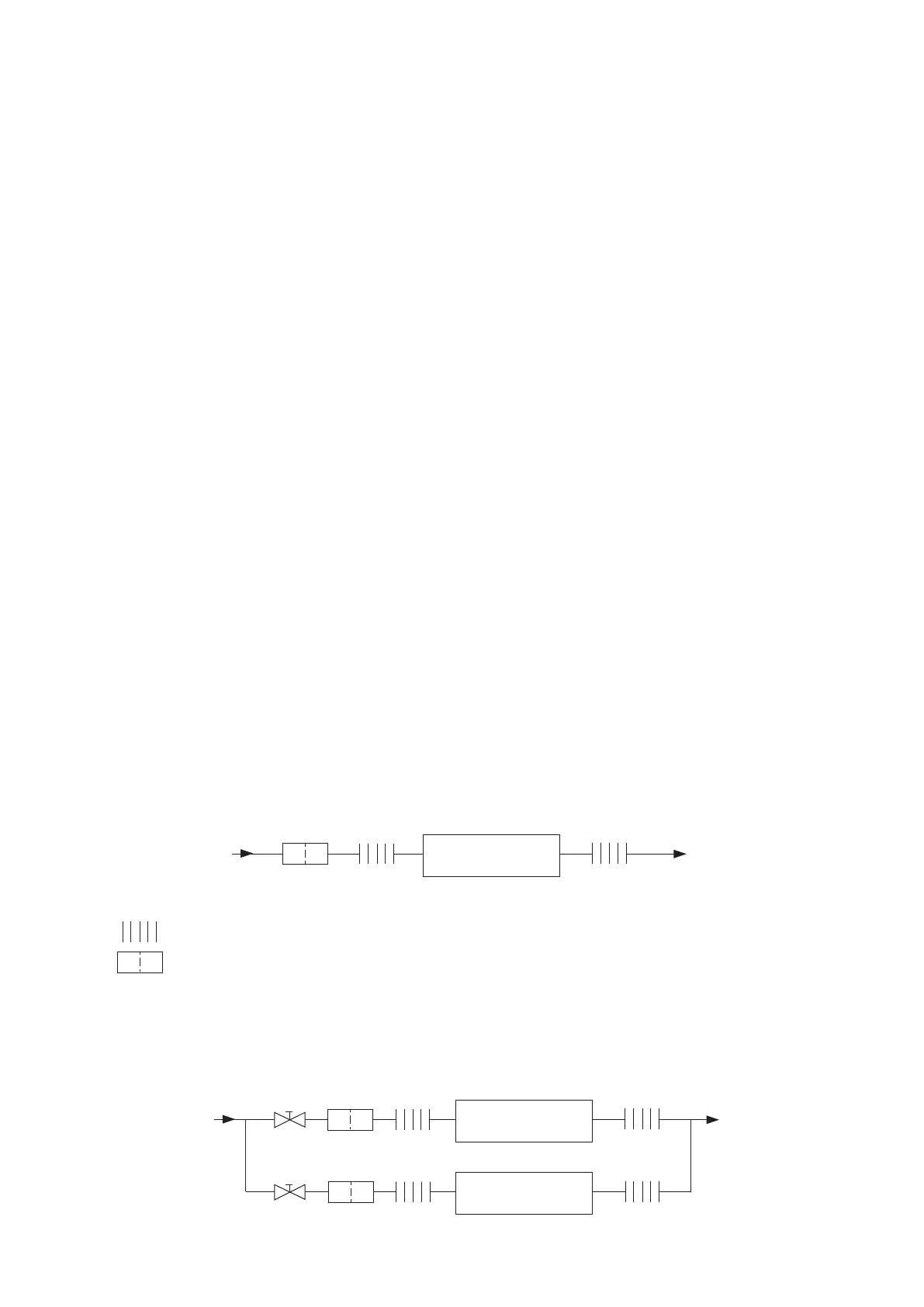

5.3 External water circuit

pipe compensator

mesh strainer

Chiller

flow waterreturn water

The chilled water circuit of the chiller contains a tube evaporator, several drain valves, several deventilation

valves, a flow monitor, a frost protection thermostat and temperature sensors in the inlet and outlet. The frost

protection thermostat is adjusted on 4°C in the factory. Below this water inlet temperature it releases a frost

protection management by the controller, which may lead to an antifreeze alarm. The adjusted value can be

modified and must be adapted to the local conditions (glycol content).

In addition to this, the free cooling version disposes of two motor driven control valves and another tempera-

ture sensor in the chilled water circuit.

The following additional components are necessary:

tank is recommended if the water volume of the water circuit is less than 10 litres/kW cooling capacity. The

storage tank should be lined out with thermical insulation.

The expansion tank must be dimensioned in such a way that the water circuit volume can increase by 2%

without draining off liquid through the safety valve.

repair works without having to drain the entire circuit.

recommended: pipe compensator in the chilled water inlet and outlet

Another criterion for the external water circuit is the water quality. The most sensible component in respect

of pollution and corrosion is the tube evaporator, whose heat transmission features deteriorate in this case.

The water should be free from solid particles. For this purpose we recommend the installation of a fine mesh

strainer upstream the evaporator.

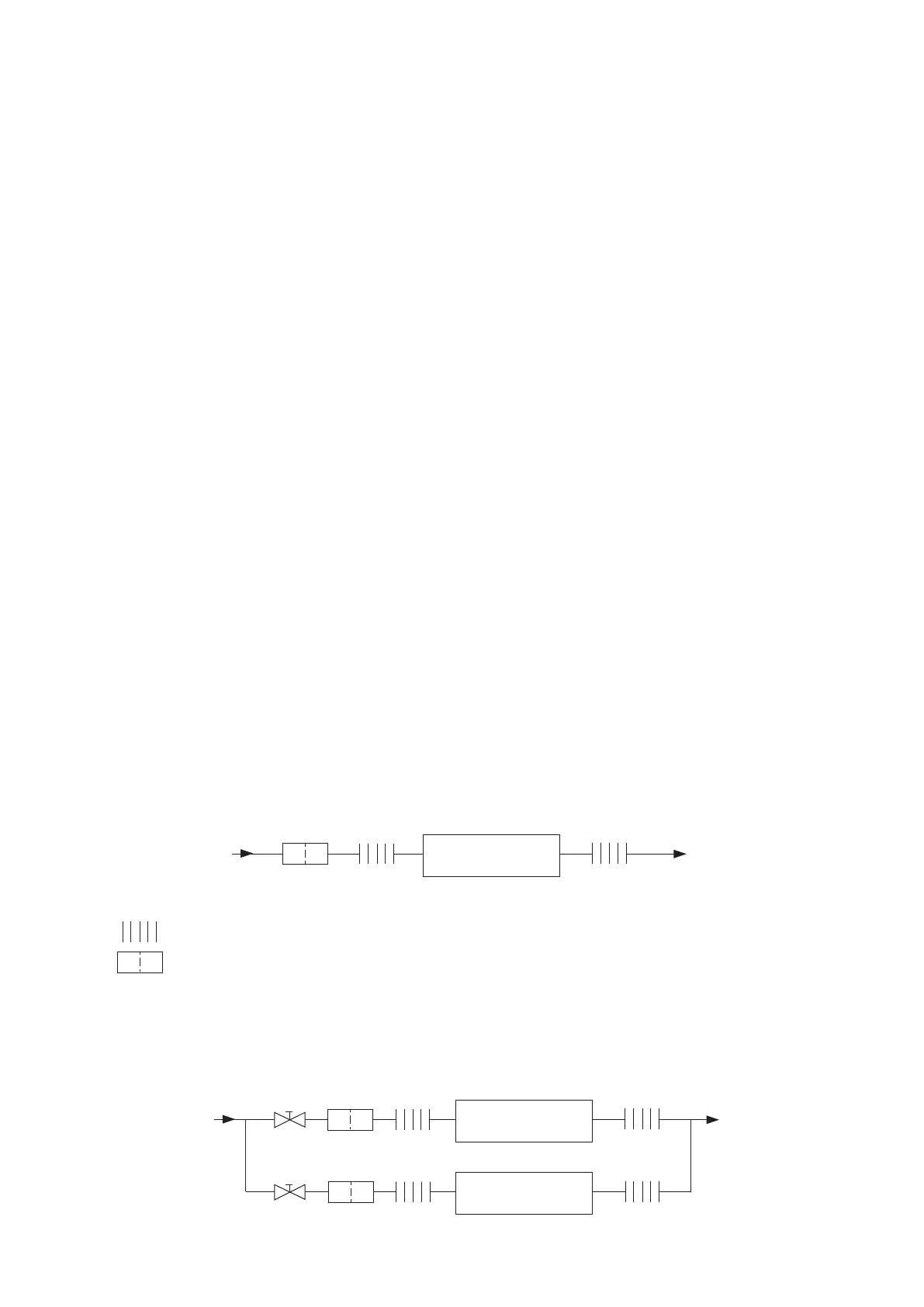

If you connect two or more chillers in parallel, we recommend to install regulating valves to keep the pressure

drop of each unit equally high.

Chiller 1

Chiller 2

flow waterreturn water

Loading...

Loading...