Section 2

DESCRIPTION

5

2.1 INTRODUCTION

Your new Sullair flood-lubricated rotary screw air

compressor will provide you with a unique experi-

ence in improved reliability and greatly reduced

maintenance.

Compared to other types of compressors, the

Sullair rotary screw is unique in mechanical reliabil-

ity, with “no wear” and “no inspection” required of

the working parts within the compressor unit.

Read Section 7 (Maintenance) to see how surpris-

ingly easy it is to keep your air compressor in top

operating condition.

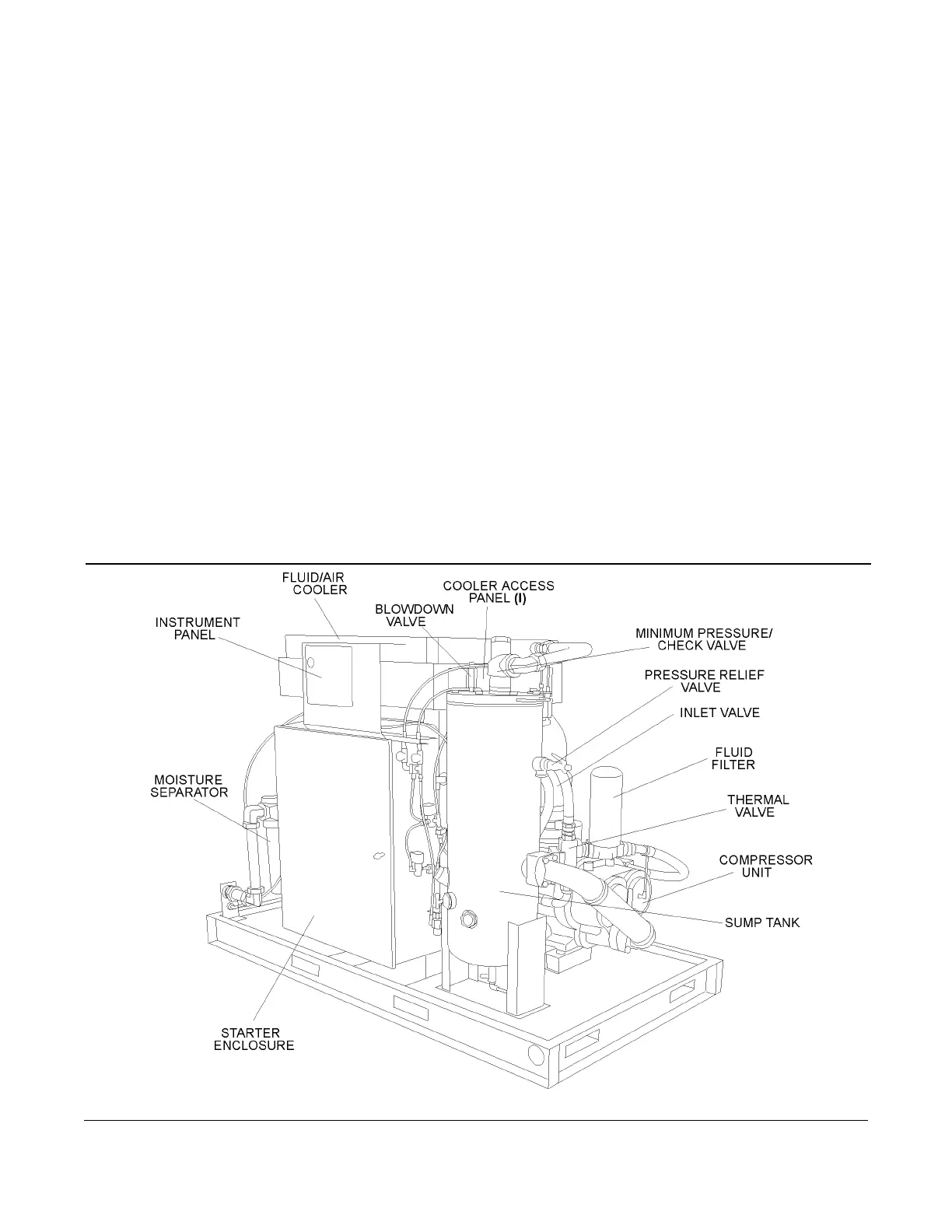

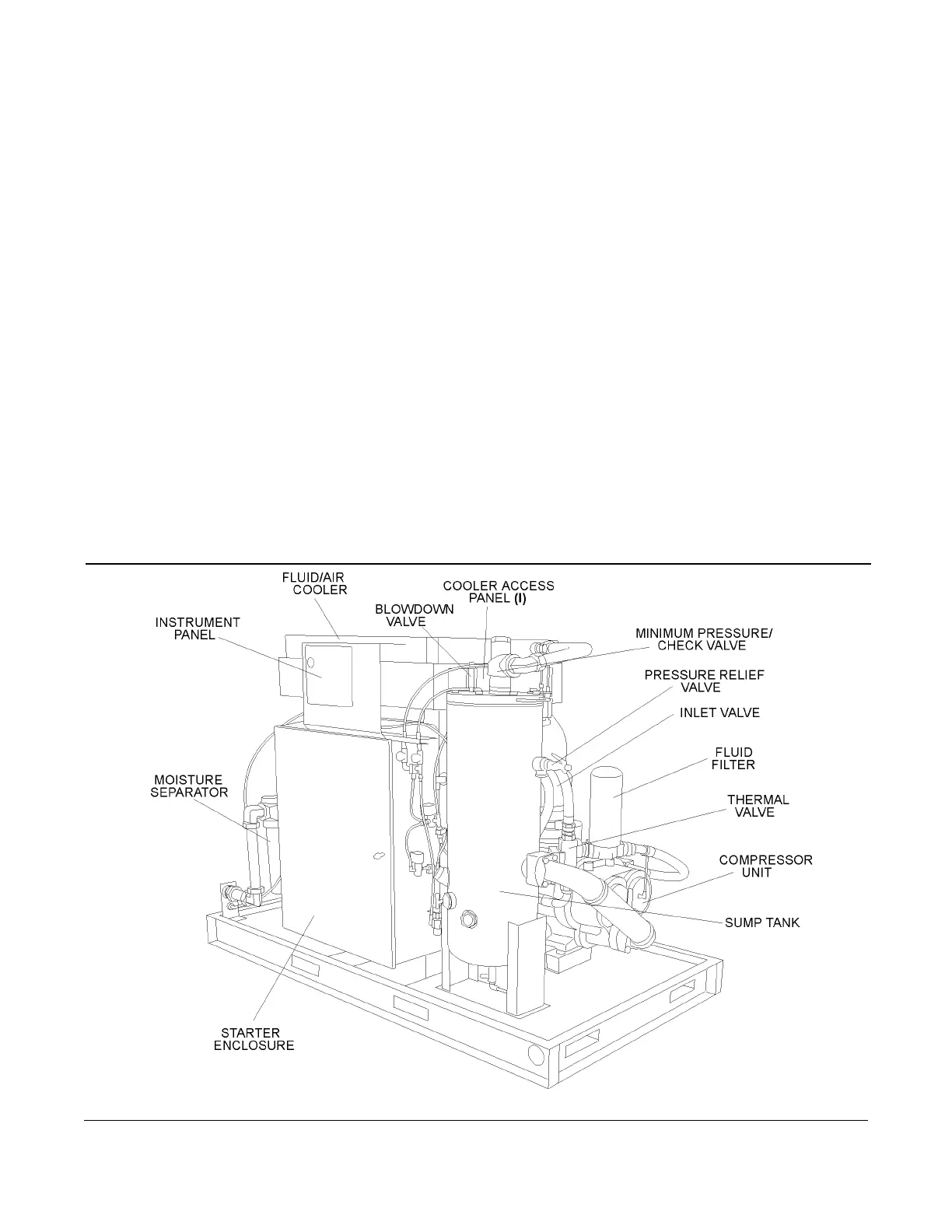

2.2 DESCRIPTION OF COMPONENTS

Refer to Figures 2-1A, 2-1B and 2-2. The compo-

nents and assemblies of the air compressor are

clearly shown. The complete package includes

compressor, electric motor, starter, compressor

inlet system, compressor discharge system, com-

pressor lubrication and cooling system, capacity

control system, instrument panel, aftercooler, a

combination separator and trap, all mounted on a

heavy gauge steel frame.

On air-cooled models, a fan draws air over the

motor and forces it out through the combined after-

cooler and fluid cooler thereby removing the com-

pression heat from the compressed air and the

cooling fluid.

On water-cooled models, a shell and tube heat

exchanger is mounted on the compressor frame.

Fluid is piped into the heat exchanger where com-

pression heat is removed from the fluid. Another

similar heat exchanger cools the compressed air.

Both air-cooled and water-cooled versions have

easily accessible items such as the fluid filters and

control valves. The inlet air filter is also easily

accessible for servicing.

2.3 SULLAIR COMPRESSOR UNIT, FUNCTIONAL

DESCRIPTION

Sullair air compressors feature the Sullair compres-

sor unit, a single-stage, positive displacement,

flood lubricated-type compressor. This unit provides

continuous compression to meet your needs.

Figure 2-1A Sullair Rotary Screw Air Compressor- Air-cooled (typical component layout)

(I) DO NOT Operate compressor without cooler access panels in place (see Figure 2-1B).

Loading...

Loading...