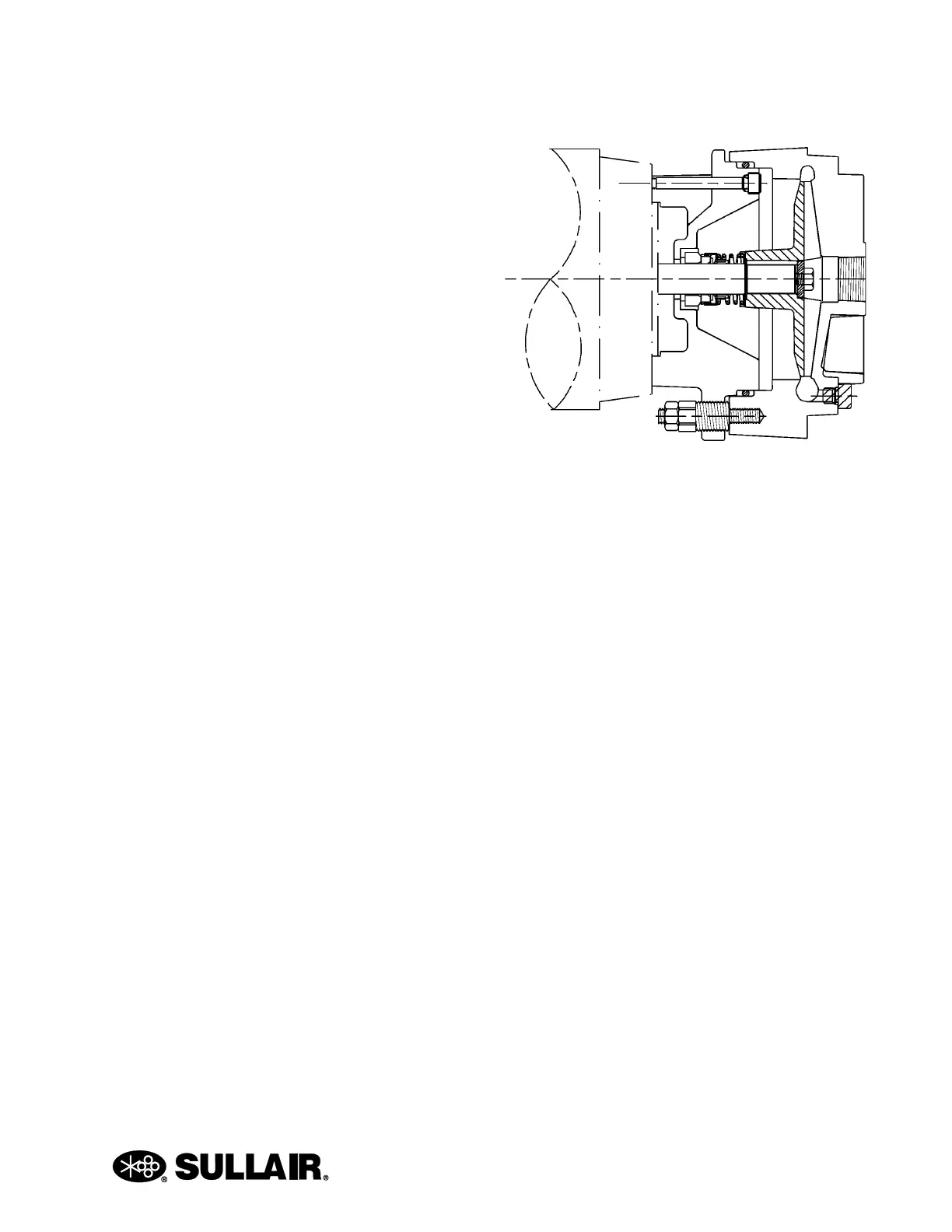

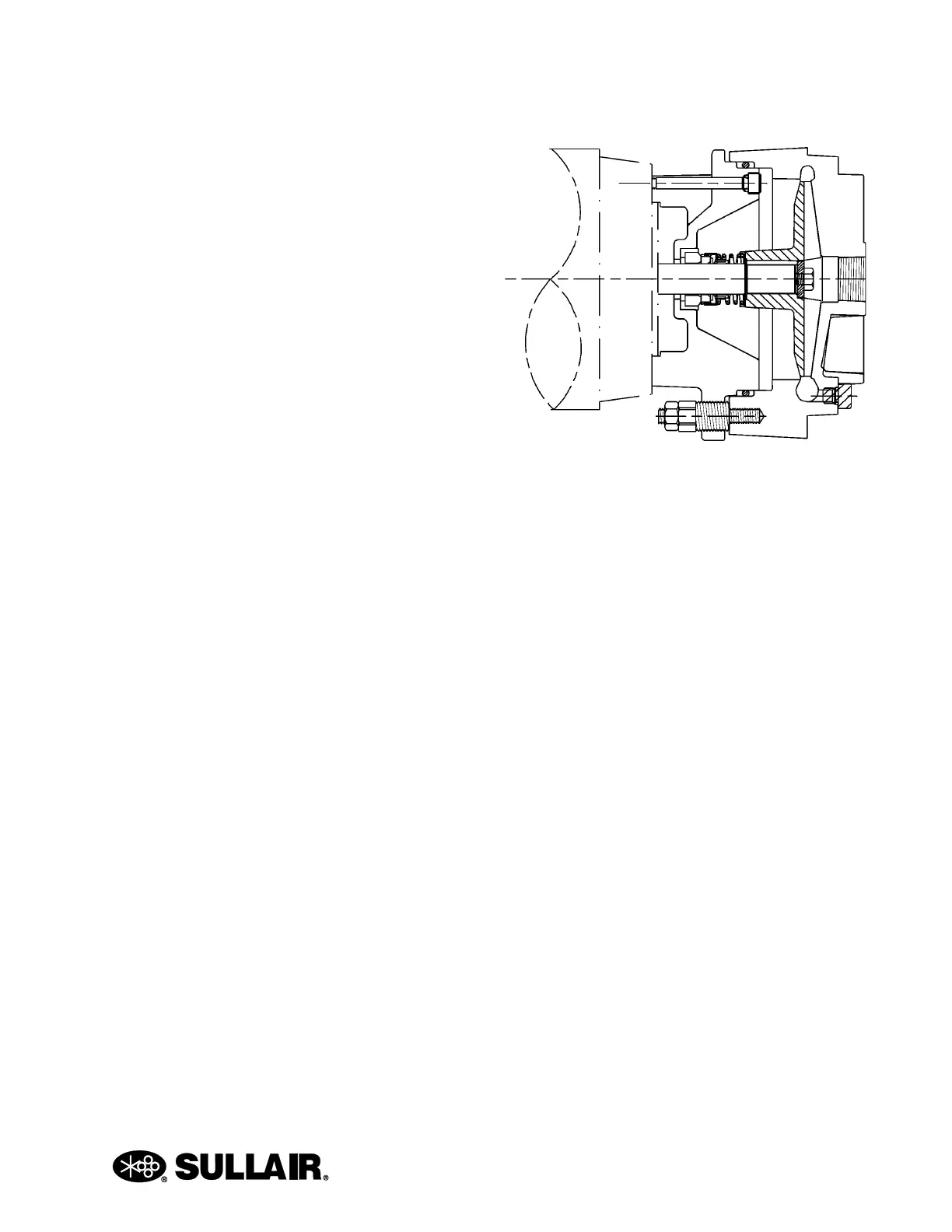

SECTION 8 HORIZONTAL CLOSE COUPLED PUMP

159

To disassemble the pump:

1. Remove all liquid from the pump.

2. Remove the casing (#108) by removing the

jam nuts (#20) from the casing studs (#5).

Slide the casing off and rest it on the studs.

3. Remove the impeller (#11) by removing the

10mm Bolt (#19) and washer (#41), then

sliding forward.(may require a gear puller)

4. Remove the snap ring (#4) from the shaft

using snap ring pliers.

5. Remove the impeller key (#23) from the

shaft.

6. Remove the rotating element from the shaft.

The element normally adheres tightly to the

shaft and some force may be necessary to

remove it. This is common and, if care is

taken, the element can be reassembled and

reused. It is recommended that a new

rotating element be used for reassembly.

DO NOT attempt to remove the seal using a

screwdriver or other sharp object. Extensive

damage to the shaft or element could occur.

7. 7. Remove the motor bracket. Loosen and

remove the four socket head screws (#33A)

with a 5 mm Allen wrench.

Note: The rotating element must be removed

before the motor bracket can be removed. It

is not necessary to remove the adjusting

screws # 33.

8. 8. Remove the seat portion of the seal from

the motor bracket.

a. Place the motor bracket face down on a flat

surface.

b. Look into the opening in the center of the

motor bracket, you will see a portion of the

seat.

c. Insert the 3/4” dowel and, very gently, tap the

seat until it drops out.

d. Care must be taken with the seats. They are

often a brittle material and are prone to

breakage. It is recommended that a new

replacement seat be installed during

reassembly.

8.2.3 INSPECTION OF COMPONENTS

Thoroughly clean all parts. All components should be

examined for wear and corrosion. Replace any parts

that show visible wear.

The “O” rings and other elastomeric components

should be replaced if they have been deformed or

cut.

If seal components must be reused, carefully inspect

for microscopic cracks and nicks. Scratches that

might be ignored elsewhere can produce leakage if

they are on seal carbons and seat wearing surfaces.

Cleanliness is imperative when working with

mechanical seals. Microscopic grit and particles

between seal faces can be, and often are, the cause

of early seal failures.

If the impeller can be rocked or wobbled on the shaft,

it is too loose and must be replaced.

Check the shaft for galling, pitting, and corrosion. If

the shaft is corroded where the seal elastomer

comes in contact with it, the motor must be replaced.

Surface corrosion must be removed so that seals can

slide freely during assembly. The shaft diameter

should be no smaller than .002” below the nominal

fractional seal sizes. Remove any nicks or burrs

which may have occurred during disassembly. Re-

clean parts as necessary.

8.2.4 REASSEMBLY

All parts should be visually inspected and cleaned or

replaced as outlined in Section 8.2.3 above.

Loading...

Loading...