17

Section 5

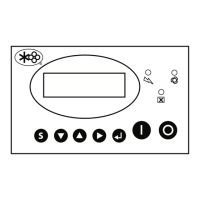

SEQUENCING TIMERS

5.1.3 EXAMPLE 3– STARTING EXAMPLE (pressure drops below lowest

pressure setting)

Machines will start when the system pressure drops below the Lowest Pressure setting, or

when system pressure drops below the load setting for a period of time determined by the

Delayed Start timer. The following example shows operation when the pressure drops below

the Lowest Pressure setting. A later example will show how the Delayed Start timer works

(ie. the pressure is below the Load setting but above the Lowest Pressure setting).

Suppose there are three machines where one is in trim, and two are stopped. The Lowest

Pressure setting is 70 psi.

Machine

Status

1 Trim

2 Stopped (Next machine in sequence)

3 Stopped

If the system pressure drops below the lowest pressure setting (70) the next machine in

sequence (2) will start and trim, the previously trimming machine (1) will go to full load.

Machine Status

1 Full Load

2 Trim

3 Stopped (Next machine in sequence)

The next machine in sequence will wait for 10 seconds before starting if the pressure stays

below 70. If the pressure goes above 70 the machine will start after the Delayed Start timer

expires (explained later).

5.1.4 EXAMPLE 4– STARTING EXAMPLE (pressure between lowest and load

pressure setting)

The Delayed Start timer comes into play only when the system pressure is below the

Sequencing Load pressure setting but still above the Lowest Pressure setting. This timer

value is prorated between the Sequence Load pressure and Lowest Pressure.

For example if the Load Pressure is 100 and the Lowest Pressure is 70 then:

If System Pressure is above 101 and drops to (and stays at) :

99, machine will start in about 2 minutes.

85 machine will start in about 1 minute.

70 machine will start in about 30 seconds.

Suppose there are three machines where one is in trim, and two are stopped. The Lowest

Pressure setting is 70 psi.

Machine

Status

1 Trim

2 Stopped (Next machine in sequence)

Loading...

Loading...