12

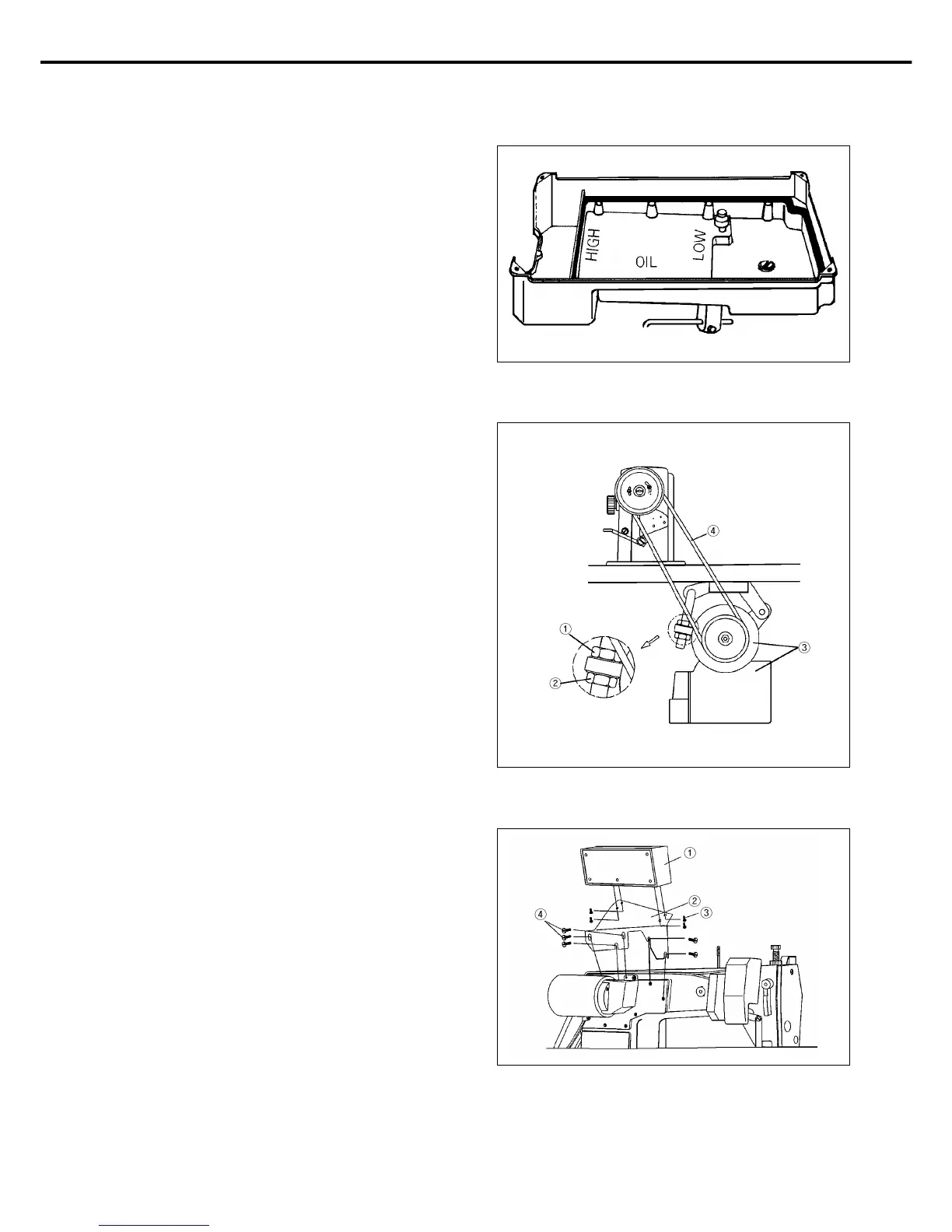

(2) Lubricating the oil fan

A. Fill the lubricant up to the “HIGH”mark. (See

Fig.5.)

B. The lubricant must be SUNSTAR’s oil provided

exclusively for industrial sewing machines or

SHELL’s Tellus C10.

C. If the oil in use is down to the “LOW”mark, fill in

to “HIGH”immediately.

D. Once every two weeks is deemed the appropriate

interval for oil refills.

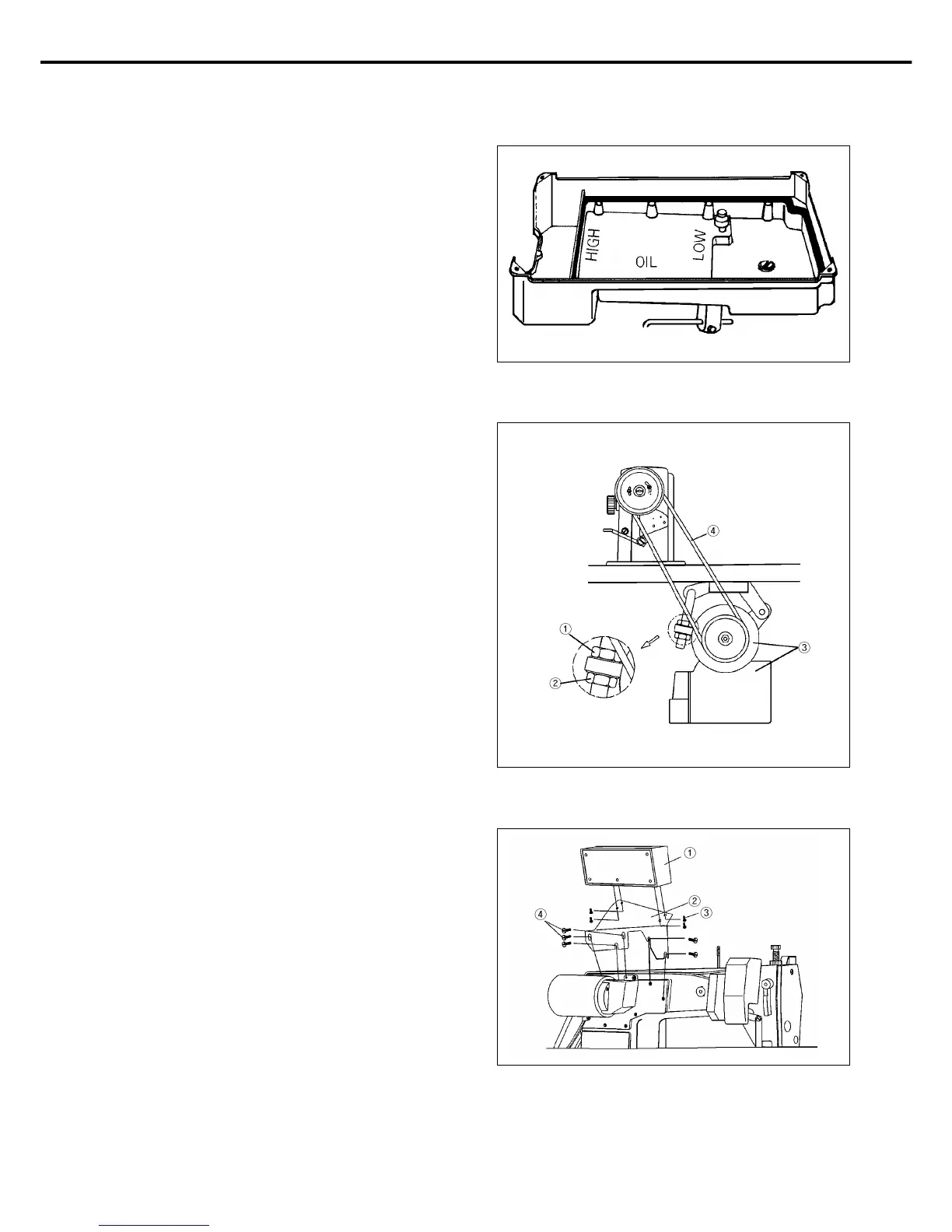

5) Belt Tension Adjustment

Sufficient loosening of the fixed nuts①, ② after motor③

installation would create tension to the belt④. Tighten the

fixed nut① first and then tighten the fixed nut② to an

unmovable position. (See Fig. 6)

[Fig.5]

[Fig.6]

6) Program Unit

(1) Installing automatic knee-lifting solenoid (in

unit)

A. Use four fixing screws③ to attach the bracket② onto

the program unit①.

B. Fasten the bracket② onto the machine body, using

two fixing bolts④ and three clamp screws in the

back lid of the machine. (See Fig. 7)

[Fig.7]

Loading...

Loading...