22

KM-250/506 Series

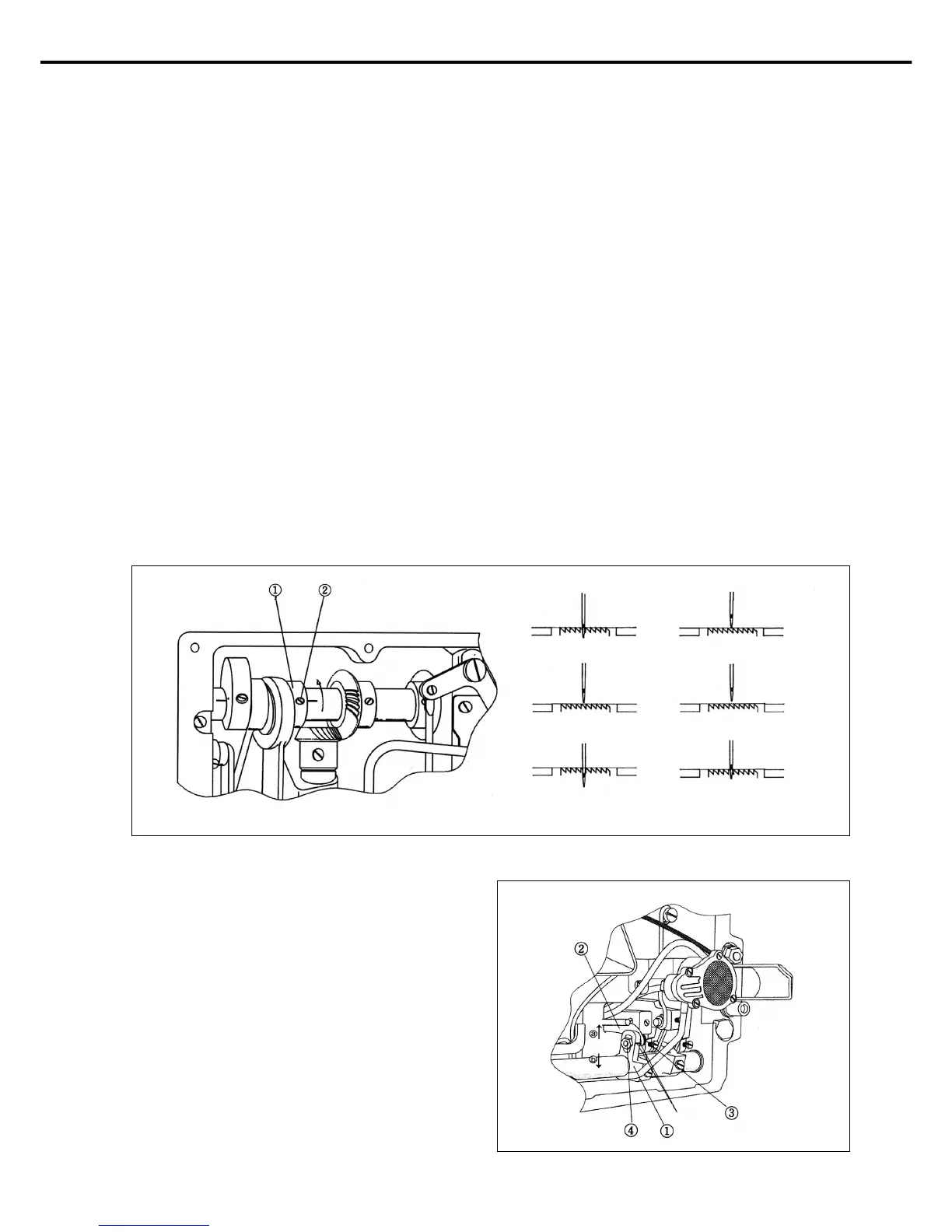

[Fig. 34]

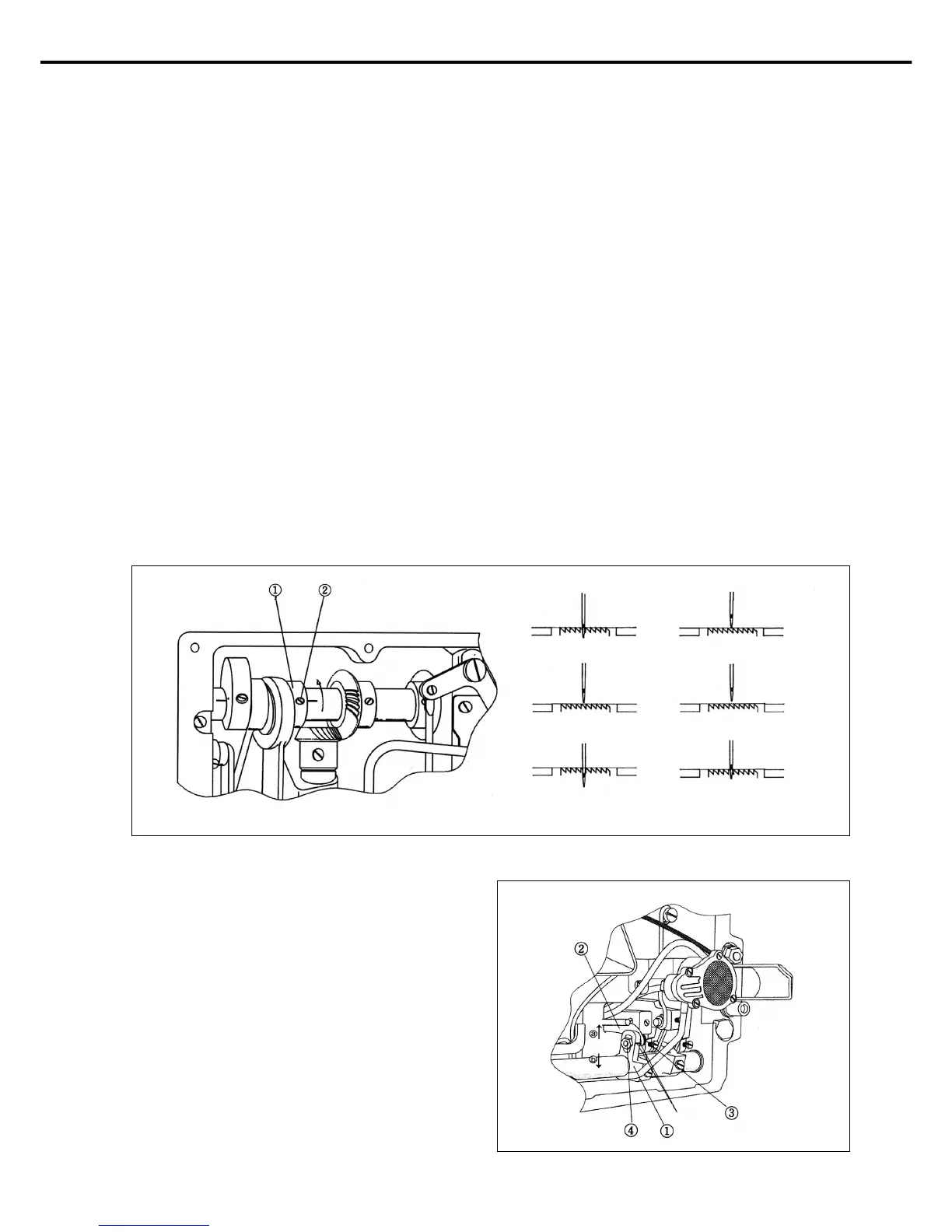

[Fig. 35]

13) Feed Cam Adjustment

The timing of the feed dog and needle is adjusted by turning the feed cam① up and down. When the pulley is turned such

that the feed dog is lowered so that the top of the feed dog is aligned with the top of the needle plate, the lower needle hole

will come in direct line with the top of the feed dog. This is the standard position. (For the KM-350/530 Series, the standard

is when the end of the needle is in line with the top of the feed dog when the top of the feed dog is aligned in height with the

top of the needle plate.)

(※ For KM-350/530 Series users, the stitch length adjusting dial must be set to “0”here.)

A. To have the appropriate amount of tension in the thread, make the feed dog movement a little slower than the needle

movement. To do this, loosen the feed cam fixing screw② and turn the feed cam① in the opposite direction of the arrow.

Then, tighten the feed cam fixing screw②.

B. To prevent material jam, make the feed dog movement a little faster than the needle movement. To do this, loosen the

feed cam fixing screw② and turn the feed cam① in the arrow direction and then tighten the feed cam fixing screw②.

KM-350/530 Series

14) Adjustment of Needle Movement (KM-350/KM-530 Series)

A. If the feed dog movement is faster than the needle movement, loosen the feed cam fixing screw② and turn the feed cam

① in the arrow direction and then tighten the feed cam fixing screw②.

B. On the other hand, if the feed dog movement is slower than the needle movement, loosen the feed cam fixing screw② and

turn the feed cam① in the opposite direction of the arrow and then tighten the feed cam fixing screw②.

(1) The standard position is when the needle feed

connecting rod② is positioned at the carved sign marked

on the horizontal pushing crank (back)①.

(2) To increase the feed dog movement over the needle

movement, loosen nut③ and adjust the needle feed

connecting rod④ in ⓐ direction and then tighten nut③.

The feed dog movement can increase about 20% in

excess of the needle movement and this adjustment is

especially effective for slippery material or thick

material, which are susceptible to jams.

(3) In contrast, turning the needle feed connecting rod② in

ⓑ direction would decrease needle movement such that

it would be smaller than the feed dog movement.

Carved

Sign

Needle

Needle Plate

Feed Dog (standard position)

(When the feed dog is fast)

(When the feed dog is slow)

KM-250/506 Series

Needle

Needle Plate

Feed Dog (standard position)

(When the feed dog is fast)

(When the feed dog is slow)

KM-350/530 Series

Loading...

Loading...