15

Caution

▶ Always turn off the power when mounting a needle.

▶ If the operator mistakenly steps on the pedal while the power is on, the machine will start automatically

and can result in physical injuries.

▶ When using clutch motor, be aware that the motor will continue to rotate for a while even after the

power is switched off due to inertia.

▶ Start to work on the sewing machine only after the motor has come to a complete stop.

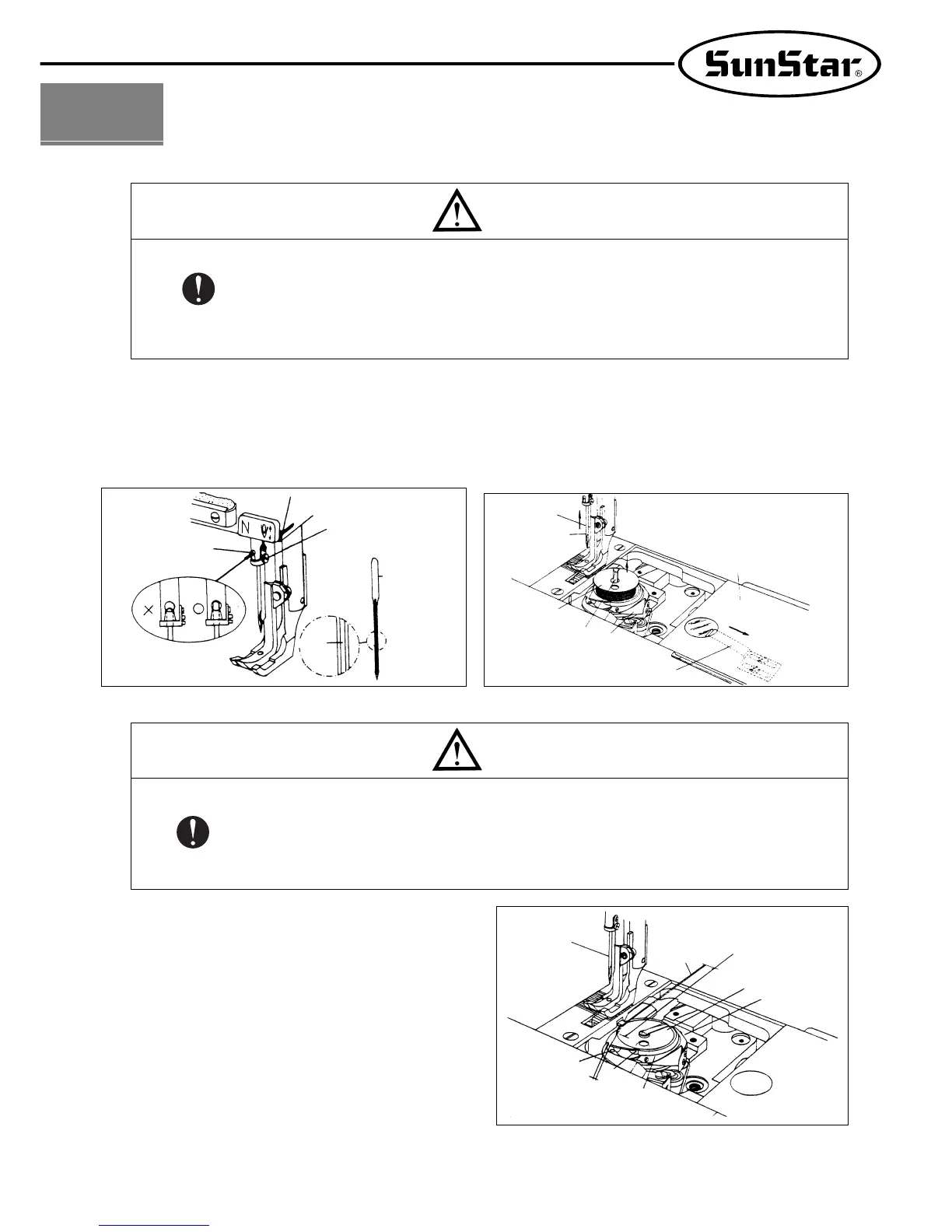

1) Inserting the needle

As in Figure 21, place the upper end of the needle closely

adhered to the upper side of the stopper hole ②, with the

needle groove ① facing left. Fix the needle with a fixing

screw ③. (See Figure 21)

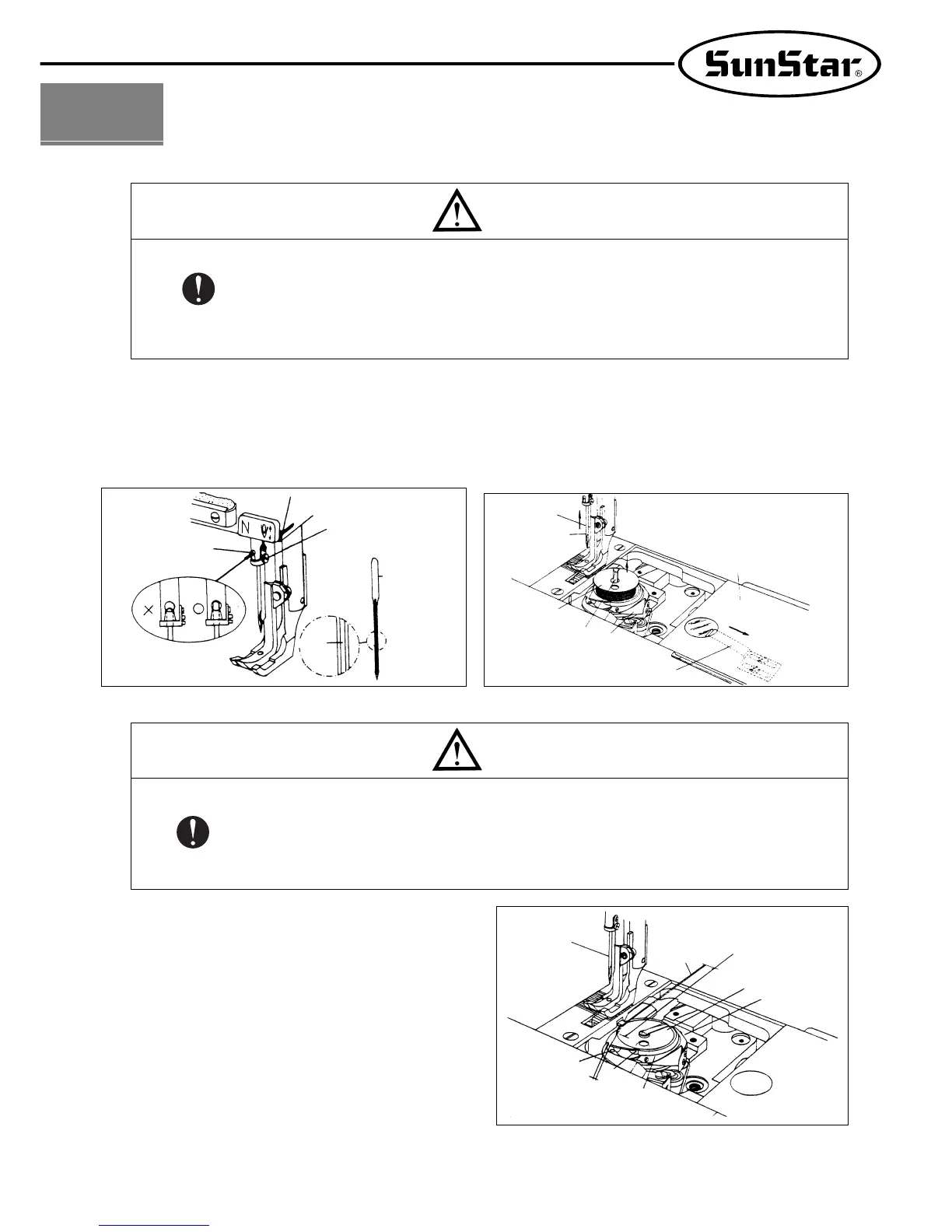

2) Removing bobbin

Place the needle ① in the highest position.

And then as in Figure 22, after pressing the slide plate

stopper ⑤, open the slide plate ④ and lift the bobbin

holder ⑦ to remove the bobbin ⑧. (See Figure 22)

3

Adjustment of the Machine

3) Winding the lower thread

Insert the bobbin ⑧ into the hook ⑥. As seen in Figure 23,

insert the thread through part of the hook and pull it out

from the end of the lower thread tension adjustment plate

⑨. And then pull the thread through the clearance ⑪

between the hook ⑥ and opener ⑩. The adequate length of

the pulled-out lower thread on the slide plate④ is 50 mm.

Caution

▶ Turn off the power when adjusting the lower thread tension.

▶ If the operator mistakenly steps on the pedal, the machine will start automatically and can cause physical

injuries.

▶ When using the clutch motor, be aware that the motor will continue to rotate for a while after the power is

switched off due to inertia.

▶ Start to work only after the motor has come to a complete stop.

[Figure 23]

[Figure 22][Figure 21]

Lower thread

③

②

①

About 50 mm

⑩

⑪

⑨

⑧

⑥

①

⑧

⑦

⑥

⑤

④

groove

Loading...

Loading...