P-97 FLAMING/BROWN MICROPIPETTE PULLER OPERATION MANUAL – REV. 2.43 - DOM (20161118)

32

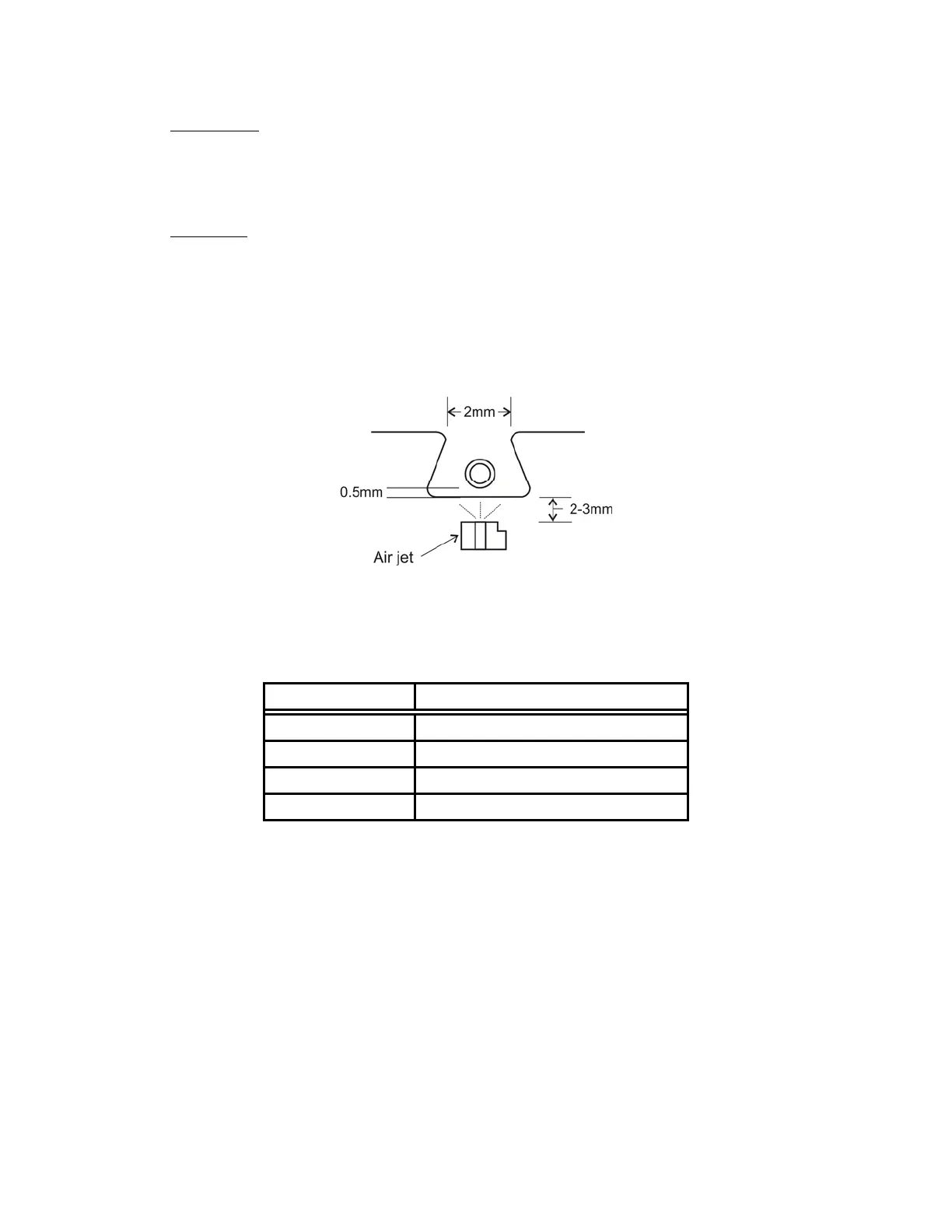

3.6.4.1 Positioning

When using the trough filaments, the glass tubing should be positioned just above the bottom

of the filament (approx. 0.5mm), and centered between the two sides (Figure 3-15). See

section Error! Reference source not found. for adjustments and alignment.

3.6.4.2 Geometry

The geometry of the trough filament is an important factor for proper heat application to the

glass. Replacement trough filaments should have a profile similar to that illustrated in

Figure 3-15, where the distance between the top corners (distance A) is approximately 2/3 the

length of the bottom of the filament. This geometry will provide improved heat distribution

to the top of the glass tubing. When replacing a filament, check the new filament geometry. If

it differs appreciably from the ideal, you can easily modify it by grasping the bottom corners

with non-serrated forceps and gently pushing on the horizontal ‘wings’.

Figure 3-16. Trough filament positioning.

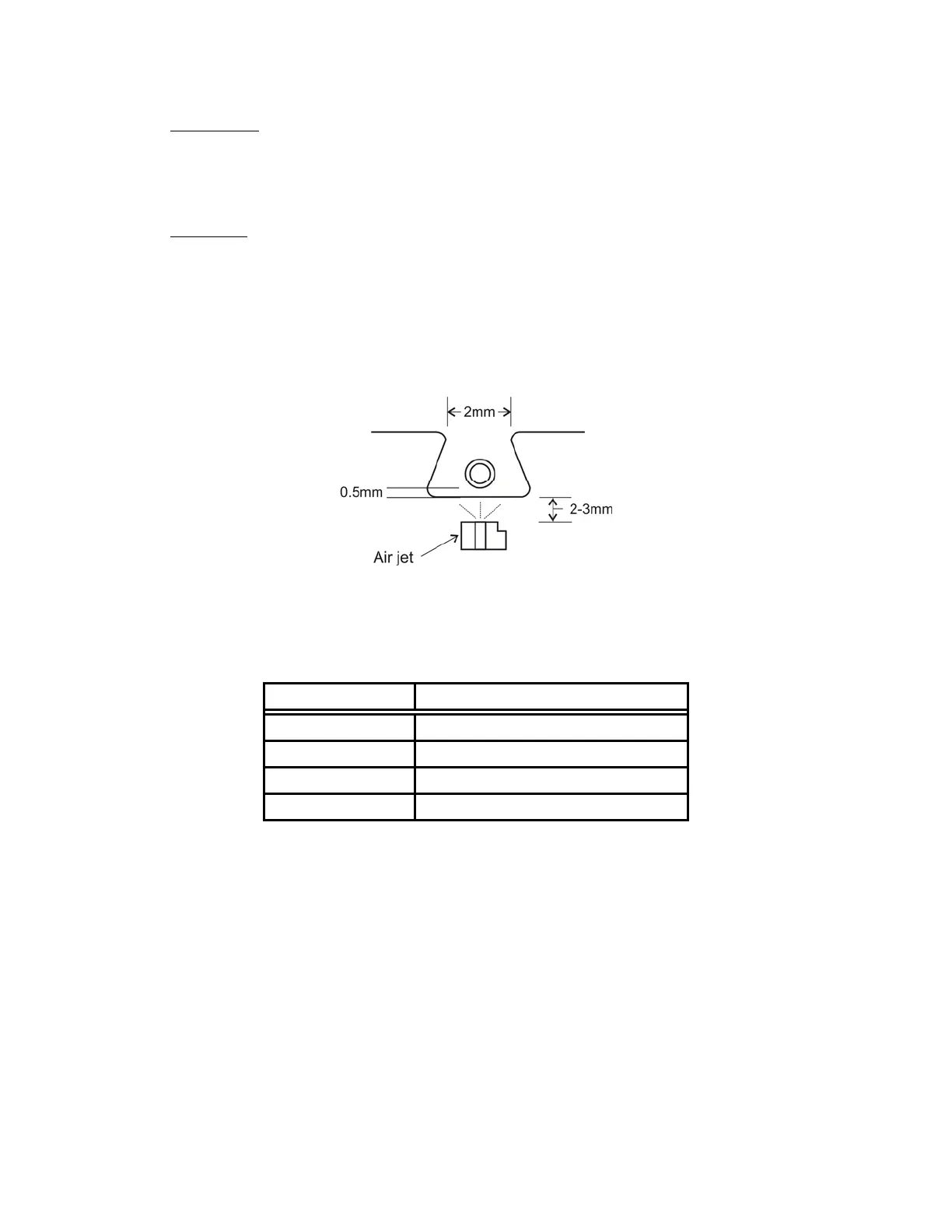

The trough filament you select depends upon the length of the taper that you want. Wider

filaments for special purposes are available upon request.

Table 3-5. Trough filament sizes.

Filament Description

FT315B 1.5mm wide trough

FT320B 2mm wide trough

FT330B (standard) 3mm wide trough

FT345B 4.5mm wide trough

Loading...

Loading...