INSTALLATION OF:

SHOWER SYSTEMS AND

TUB/SHOWER SYSTEMS

Tools required for installation of this

product are: Phillips screw driver, tubing

cutter, teon tape, soldering equipment,

adjustable wrench and channel-lock pliers.

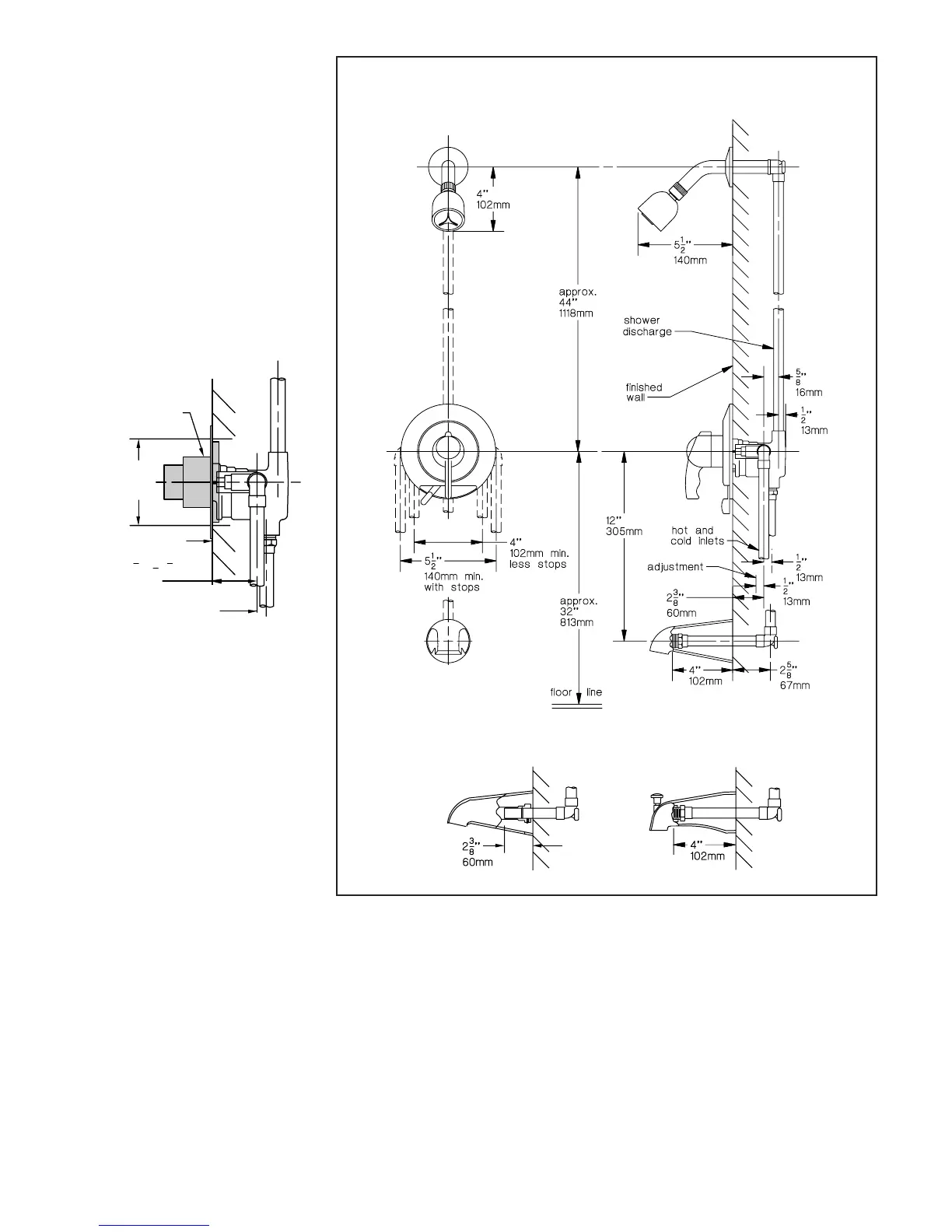

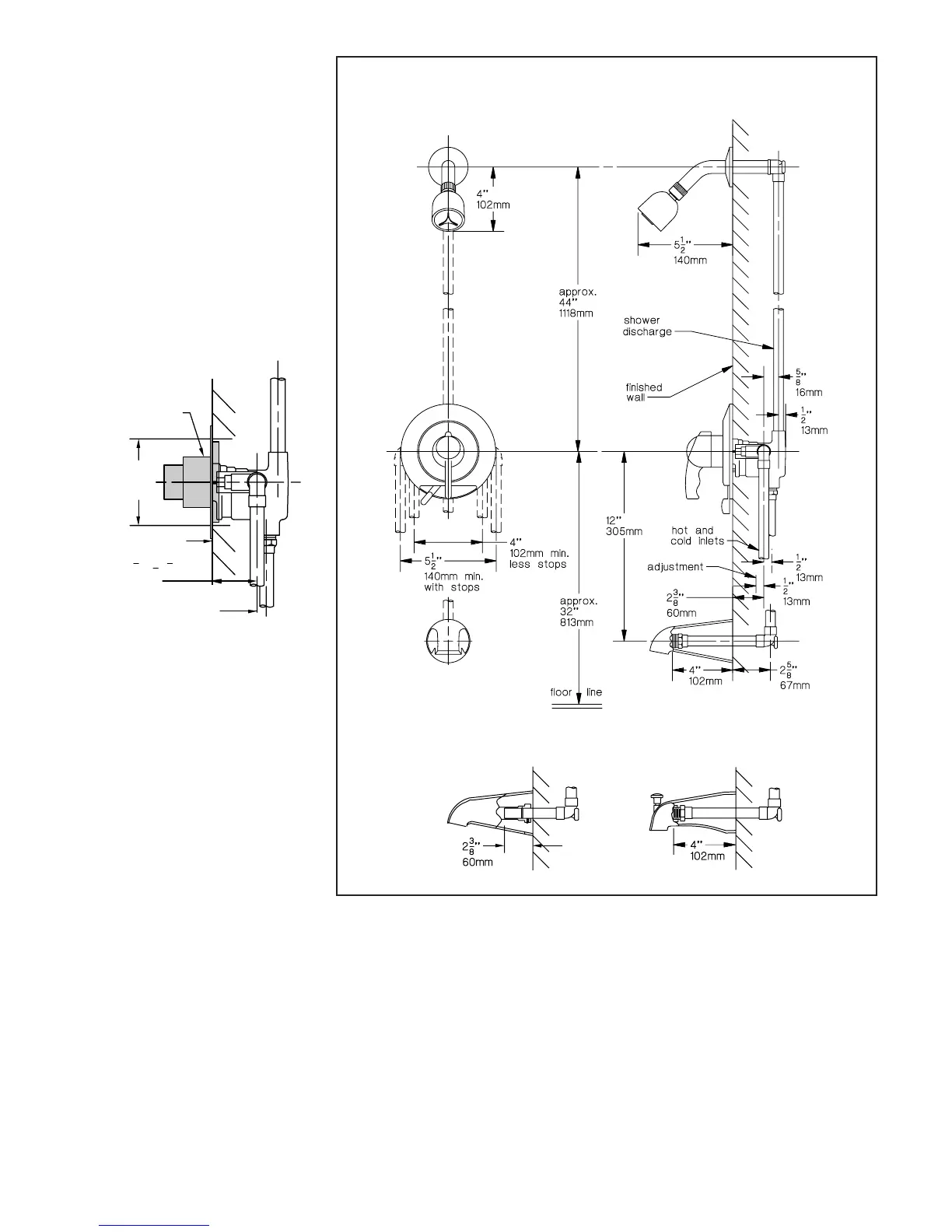

1. Install piping and ttings with valve

body as shown in Figure 2 or 3.

IMPORTANT: Valve rough-in is 2-3/8”

+/- 1/2” from CENTERLINE OF

SUPPLIES TO FACE OF FINISH WALL.

Install so that line indicated on rough-in

plaster shield on valve is ush with

nish wall as shown in Figure 1.

Tub/Shower System (Figure 2)

Model A

Pipe shower head from outlet marked

“S” and to tub spout from outlet

marked “T”. DO NOT SUBSTITUTE

OTHER OUTLET ACCESSORIES FOR

THE TUB SPOUT (such as HOSE

AND SPRAY, SHOWER HEAD,

BODYSPRAY, LEDGE SPOUTS, ETC.)

The diverter-mechanism in this valve is

so designed that it cannot be subject

to any back pressure, other than is

imposed by the spout supplied with

this package. Install HOT on left and

COLD on right according to valve

markings.

Shower System (Figure 3)

Model B

Pipe to shower head from outlet

marked “S”. DO NOT REMOVE PLUG

FROM OUTLET MARKED “T”. Install HOT

on left and COLD on right according to

valve markings.

Tub or Shower System (Figure 2A)

Model C

The valve in this system has a built-in

choke for use with a diverter spout.

Follow the instructions above.

2. When nishing tile wall REMOVE (pull

off; don’t turn) ENTIRE PROTECTIVE

ROUGH-IN SHIELD and FILL AREA

AROUND VALVE BODY WITH GROUT

OR PLASTER.

3. TURN ON HOT AND COLD SUPPLIES,

valve will not operate unless both hot

and cold water are turned on.

4. Unscrew dome cover (T-19/20) and

tighten packing nut (T-17) for positive

frictional resistance to handle turn

throughout adjustment cycle and at

shut-off position. Check valve cap,

packing nut, diverter spindle o-ring and

all valve, pipe and tting connections

for leaks.

5. SET LIMIT STOP SCREW AS DIRECTED

AFTER “IMPORTANT” IN BOLD TYPE ON

PAGE ONE. Reattach dome cover back

onto packing nut.

6. Peel from backing and rmly press

diverter volume dial/emblem (T-143,

T-144) into position on clean, dry

escutcheon (T3-27D) and assemble

diverter volume control lever (T3-30),

shaft (T-154), and clip (T-153) into

escutcheon as shown in Figure 9.

FIGURE 2

Model A: Tub/Shower System

finish wall face

4" (101mm) Max

2

3

8

''

60mm

1

2

''

supplies

C

L

plaster shield

+

3" (75mm) Min

FIGURE 1

Suffix SS: Slip-on type spout

FIGURE 2A

Model C: Diverter spout installation

Loading...

Loading...