technical reference

72

SYNRAD OEM v40 Operator’s Manual Version 4

User I/O connections

Sample I/O circuits

Sample inputs

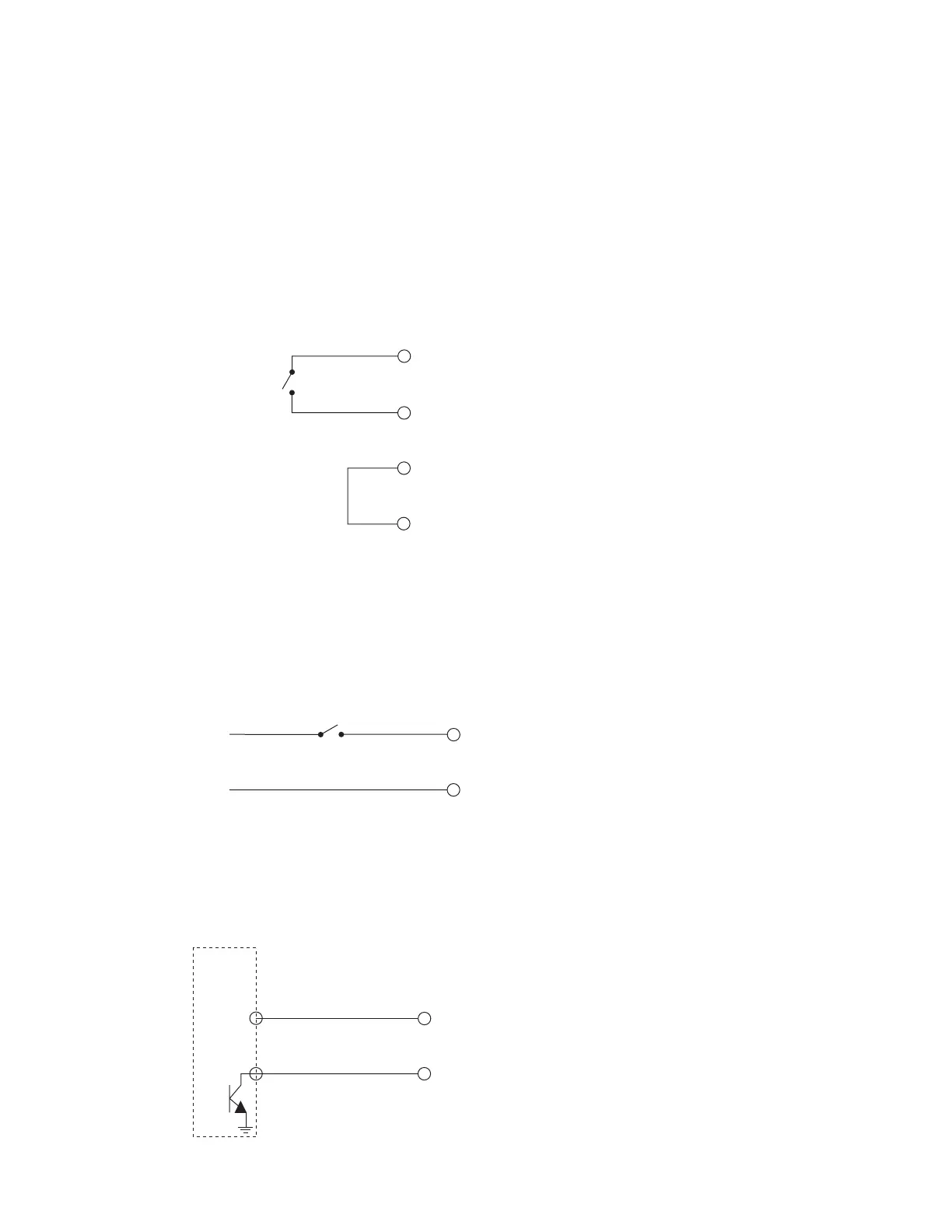

Figure below illustrates one method of supplying a Remote Interlock signal using a customer-supplied

limit switch. Firestar’s +24 VDC Auxiliary Power output powers the circuit. Note that Pin 4, +5 VDC Auxil-

iary Power, could have been used instead, depending on circuit voltage requirements.

Figure 4-10 Customer-supplied interlock

Figure below shows another variation for supplying a Remote Interlock signal to the laser. In this case,

the customer is using a limit switch and supplying a negative voltage to drive Firestar’s input circuit.

(12) AUX. DC POWER

Close switch to

le interlock

(5) +24 VDC AUXILIARY

POWER

(3) REMO

(11) INPUT COMMON

enable interlock

(3) REMO

TE INTERLOCK

(11) INPUT COMMON

–12

VDC

0 VDC

Figure 4-11 Customer-supplied interlock, negative voltage

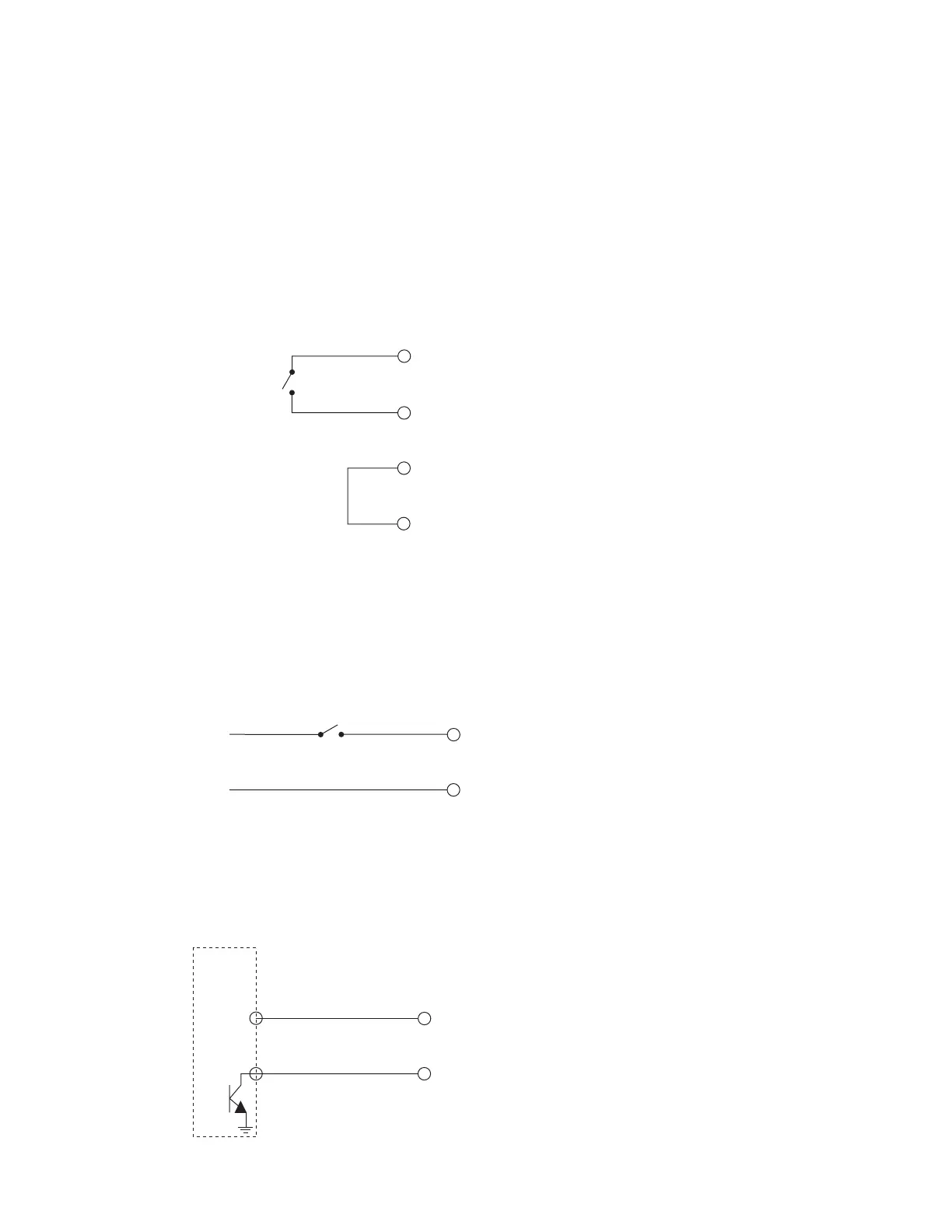

A Programmable Logic Controller (PLC) can also drive Firestar inputs. Figure below shows a typical

method for connecting to a PLC output module when only one Firestar input is used.

USER I/O PINS

(3) REMO

(11) INPUT COMMON

PLC

DC

OUTPUT

MODULE

+V

(+5–24V)

Figure 4-12 PLC driven interlock signal

Loading...

Loading...