10 I56-6304-000

DOS AND DON’TS WITH FAAST LT-200 DEVICES

Pipe network and device installation

DO:

● Clean any residues of swarf and burrs after drilling holes.

● Use the appropriate accessories in environments with

condensing humidity, to prevent moisture from entering the

device. (e.g. water trap.)

● Use appropriate lters in a dusty environment and avoid

vertical pipes feeding directly from the ceiling into the detector;

use elbows or U shaped pipes.

● Use the bracket supplied to mount it on the wall.

● Use IP rated glands on all cable entry points.

● Plan for sucient space at the side of the detector to allow the

front panel door to open fully.

● Check that all the pipes are tting together properly and there

are no air leaks or partial blockages.

● It is preferable that the exhaust is returned to the sampling

area wherever possible; this type of piping conguration will

minimise pressure dierences across the aspirating unit and

reduce the likelihood of short term ow faults.

● It is recommended that the inlet and outlet connections remain

plugged prior to use, and the outlet is temporarily sealed if the

device is turned o during maintenance periods to prevent

ingress of creepy-crawlies.

DO NOT:

● Use compressed air around the unit. If compressed air is used

to clean the pipework, completely remove the pipe connection

with the FAAST LT-200 detector. Also any cleaning of the pipes

with a vacuum cleaner must be done with pipes disconnected.

● Bend the pipes; use 45° or 90° swept bends.

● Glue the pipe entering the inlets or outlets of the FAAST LT-200.

The product is designed to fasten without glue. Certain glues

could damage the plastic of the device. If excessive glue is

used it may enter into the device and compromise the internal

functioning. Devices with glued pipes are automatically classed

as out of warranty because they cannot be tested.

● Use the device in a corrosive environment.

● Install the product on the ceiling, or in any orientation other than

vertically on a wall.

● Drill the detector case without using a sealing gland; this will

compromise its IP rating.

Device operation and maintenance

DO

● Take particular care when removing the lters, in order to avoid

dropping any dirt or waste materials into the device or fan area.

● Always turn the aspiration system o and close sample holes

when building or other dusty works are in progress on the

installation site. Any un-piped outlet should be temporarily

sealed if the device is turned o during maintenance periods.

● Ensure the lter gasket is tted after cleaning or changing the

lter.

DO NOT

● Use aerosol smoke to test the device alarm. Canned test

smokes contain oily substances that can leave a residue and

may damage the device.

● Test the device with the inlet and/or outlet closed.

● Clean any area around or inside the device with compressed

air. If compressed air is used to clean the pipework, remove the

pipe connection with the FAAST LT-200, or install the System

Sensor Reverse Flush Pipe Cleaning unit. Any cleaning of

the pipes with vacuum cleaner must also be done with pipes

disconnected from the FAAST LT-200.

● Clean the device with any type of solvent, always use a clean

cloth.

● Insert anything into the inlet, outlet openings, or the lter, laser

sensor or the fan areas.

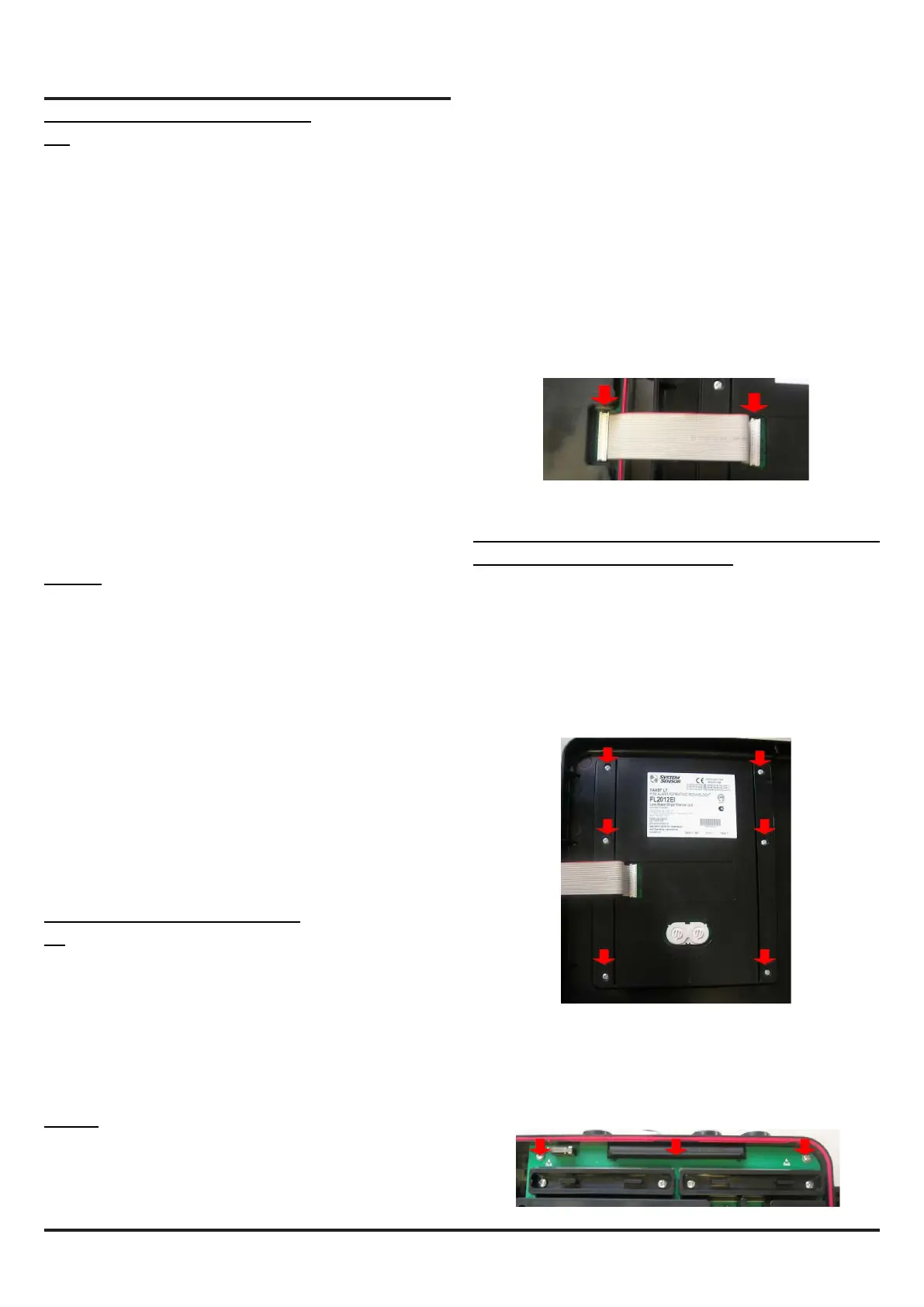

● Do not remove the exible cable connecting the PCB to the

front panel. (Figure 5: red arrows). This could compromise a

reliable connection between the two PCBs.

Figure 5: PCB cable

Actions that could aect the operability of the detector:

DO NOT DO ANY OF THE FOLLOWING:

● Glue the pipes into the inlet or outlet connections of the FAAST

LT-200 detector.

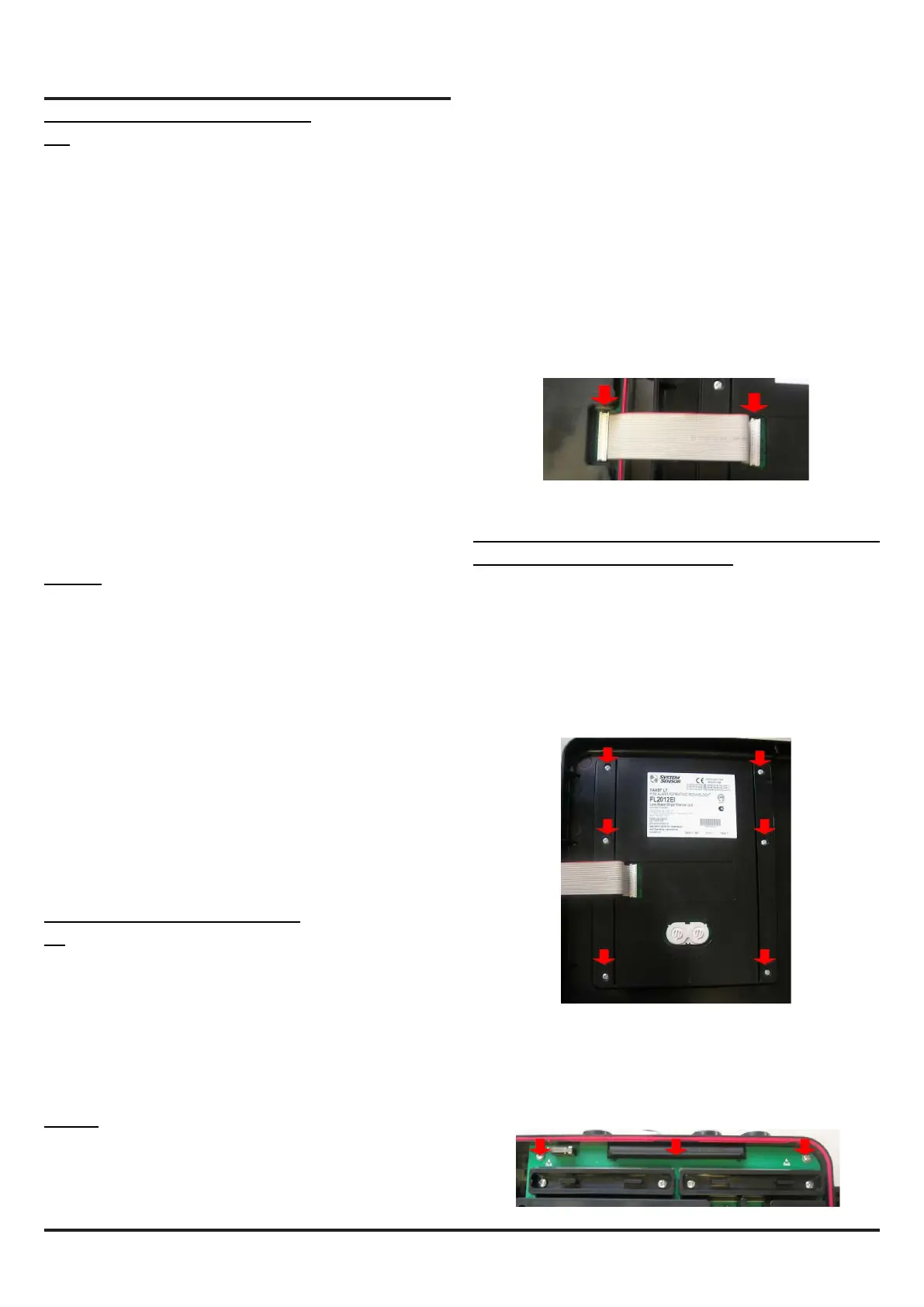

● Remove or loosen the screws (Figure 6: red arrows) xing the

PCB cover mounted onto the front panel. This could damage

the PCB or the electronic components mounted on it, and

compromise the sealing protection of the gasket.

Figure 6: Front panel PCB cover

● Loosen or remove the screws (Figure 7: red arrows) xing the

PCB on the main box. This compromises the sealing of the

device.

Figure 7: Main PCB xing screws

Loading...

Loading...