2 I56-6304-000

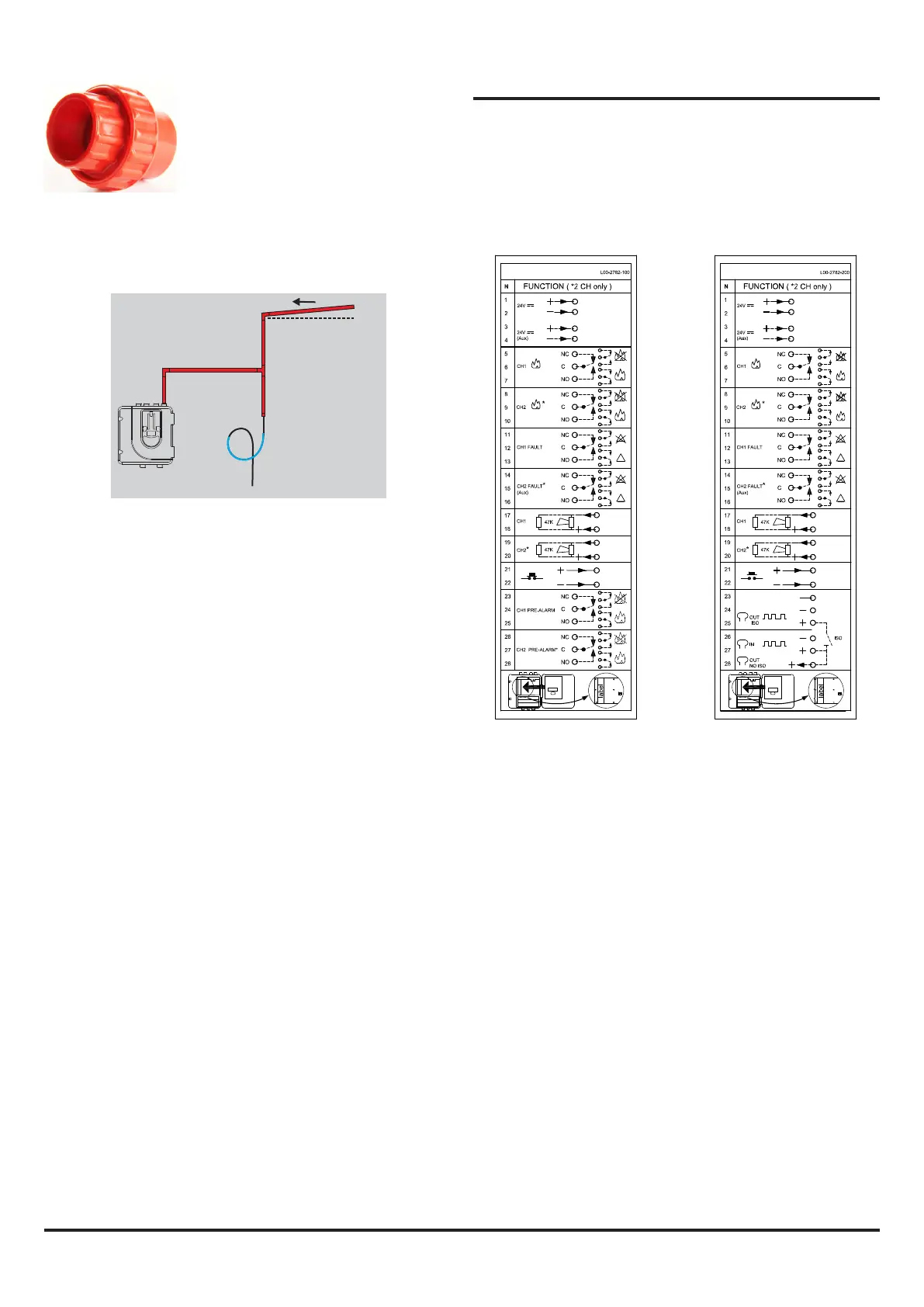

Figure 1A:

Stand-alone connections

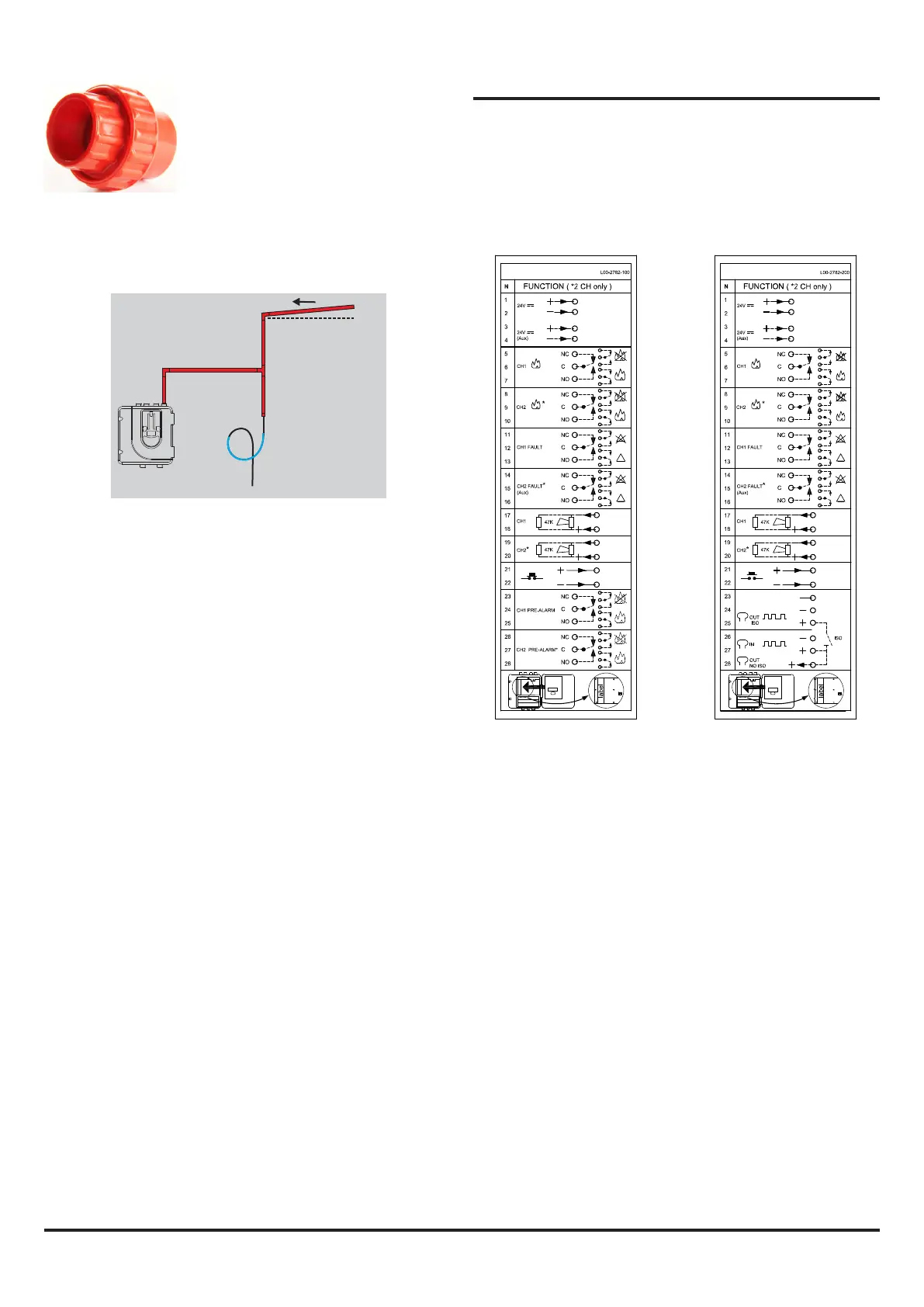

Figure 1B:

Loop-based connections

WIRING UP A FAAST LT-200 UNIT

Figures 1A and 1B show the terminal connections for FAAST

LT-200 devices. The stand-alone units (FL0111E, FL0112E and

FL0122E) are slightly dierent from the loop based devices

(FL2011E, FL2012E and FL2022E - Note: Other OEM Brands may

use dierent model numbers).

Use a socket union joint to simplify

device removal without the need to move

pipework.

Pipe Angled

Towards Trap

Capillary Primed

with Water

(No Air

Through Trap)

In damp or humid environments, be sure to t a water trap in

the pipeline before the FAAST LT-200 unit so that no liquids are

drawn into the aspirating detector. Make sure that the water trap

does not run dry or the FAAST LT-200 operation could become

compromised.

Power connections and supervision

The primary 24V power supply to the unit should be connected

to terminals 1 & 2. Terminals 3 & 4 are available for a secondary,

standby power unit if required. Terminals 1 & 2 have supervision

monitoring set as a factory default (terminals 3 & 4 are not

supervised as a default). With default settings, connecting power

to T3 & T4 without connecting T1 & T2 will give a power fault.

Sounder EOLs

The sounder output circuits have supervision monitoring and

should be tted with 47K EOL resistors. Without the EOL resistors,

the device will give a sounder fault.

Programmable input (Reset)

There is a programmable input that can have several alternate

functions. As a factory default it is congured as a Reset input that

will reset all alarms and relays. It is intended to be switched using

volt free contacts that are normally open. Leave the input open

circuit if not used.

Loading...

Loading...