6

Introduction

Models 104 & 220

070308

Running Specifications

The following are the pressure and temperature

settings recommended by Taylor for the Models 104

and 220.

Pressures

Thermostatic Expansion Valve (Suction)

Suction pressure will vary in batch style freezers due

to mix formulation, temperature, etc. At the beginning

of a freeze cycle the thermostatic expansion valve will

be wide open (high suction pressure). The Model 104

will be approximately 28 PSI. The Model 220 will be

approximately 22 PSI.

Thermostatic Expansion V alve Adjustment

Adjust higher or lower by removing the large hex cap

and rotating the slotted adjustment stem. A clockwise

adjustment will lower the pressure and a

counterclockwise adjustment will raise the pressure.

Note: Make this adjustment with mix in the cylinder

and the unit in the AUTO mode. Allow adequate time

for the pressure to stabilize.

High Side (Compressor)

Head pressure on air cooled units varies depending on

the ambient temperature. The following chart shows

normal operating pressures at various ambient

temperatures.

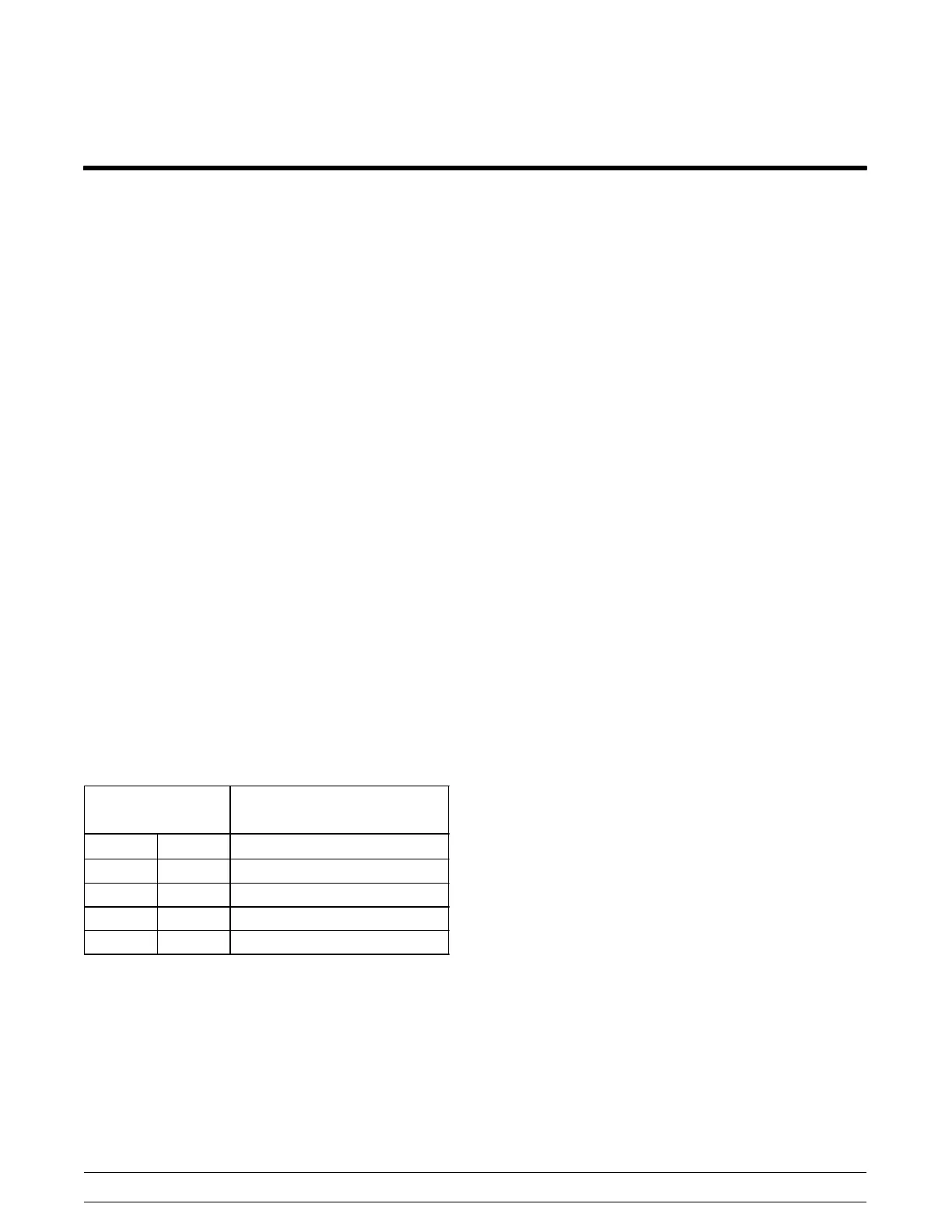

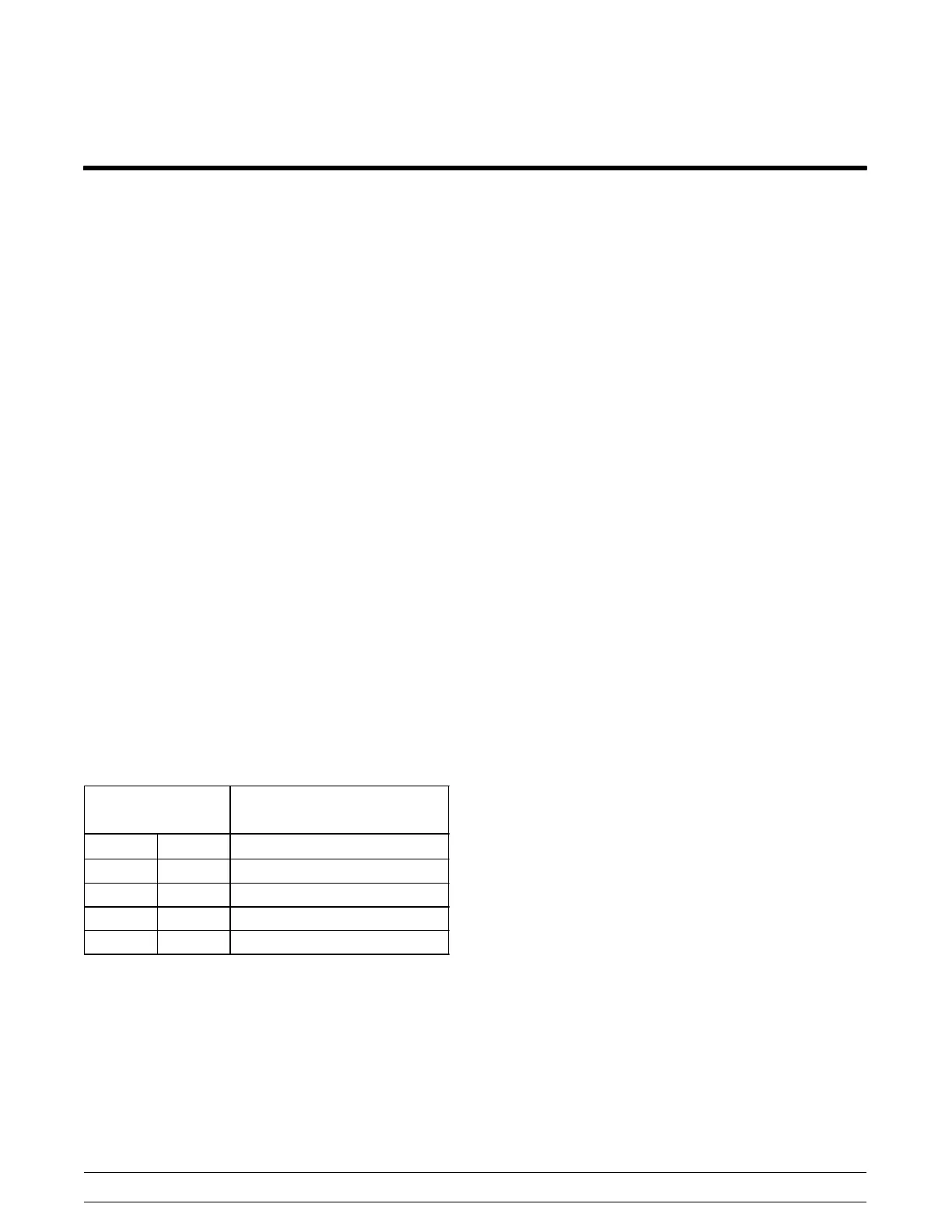

Ambient

Temperature

Normal Operating

Head Pressures

F. C. PSI

70_ 21.1_ 240 - 270 (1,655 - 1,862 kPa)

80_ 26.7_ 270 - 300 (1,862 - 2,069 kPa)

90_ 32.2_ 300 - 340 (2,069 - 2,344 kPa)

100_ 37.8_ 340 - 380 (2,344 - 2,620 kPa)

Note: This chart applies to units using R404A

refrigerant.

W ater Valve

On water cooled units, the water valve should be set

to maintain a compressor head pressure of 225--240

PSI (1551 -- 1,655 kPa).

W ater Valve Adjustment

Place a gauge on the high side access port of the

compressor. Turning the adjustment stem on the water

valve clockwise will lower the pressure. Turning the

stem counterclockwise will raise the pressure.

Note: Make this adjustment with mix in the freezing

cylinder, and the unit in the AUTO mode. Allow

adequate time for the pressure to stabilize.

Temperature

Product

Model 104: Finished product temperature should be

between 18_Fto22_F(--7.8_Cto--5.6_C).

Model 220: Finished product temperature should be

between 23_Fto25_F(--5.0_Cto--3.8_C).

Temperature Adjustment

Clockwise is the coldest setting, 22_F(--5.5_C).

Counterclockwise is the warmest setting, 26_F

(-- 3.3_C). The temperature control is factory set, but

should be checked. It is important that the coldest

setting not go below 22_F(--5.5_C).

Hopper

The mix hopper is refrigerated directly from the main

refrigeration system and is designed to keep mix at a

safe temperature during freezer operation. The mix

hopper refrigeration is not adjustable.

Loading...

Loading...