22

nd

October 2004 SC2000 Manual – 177/52301 Rev G Page 19

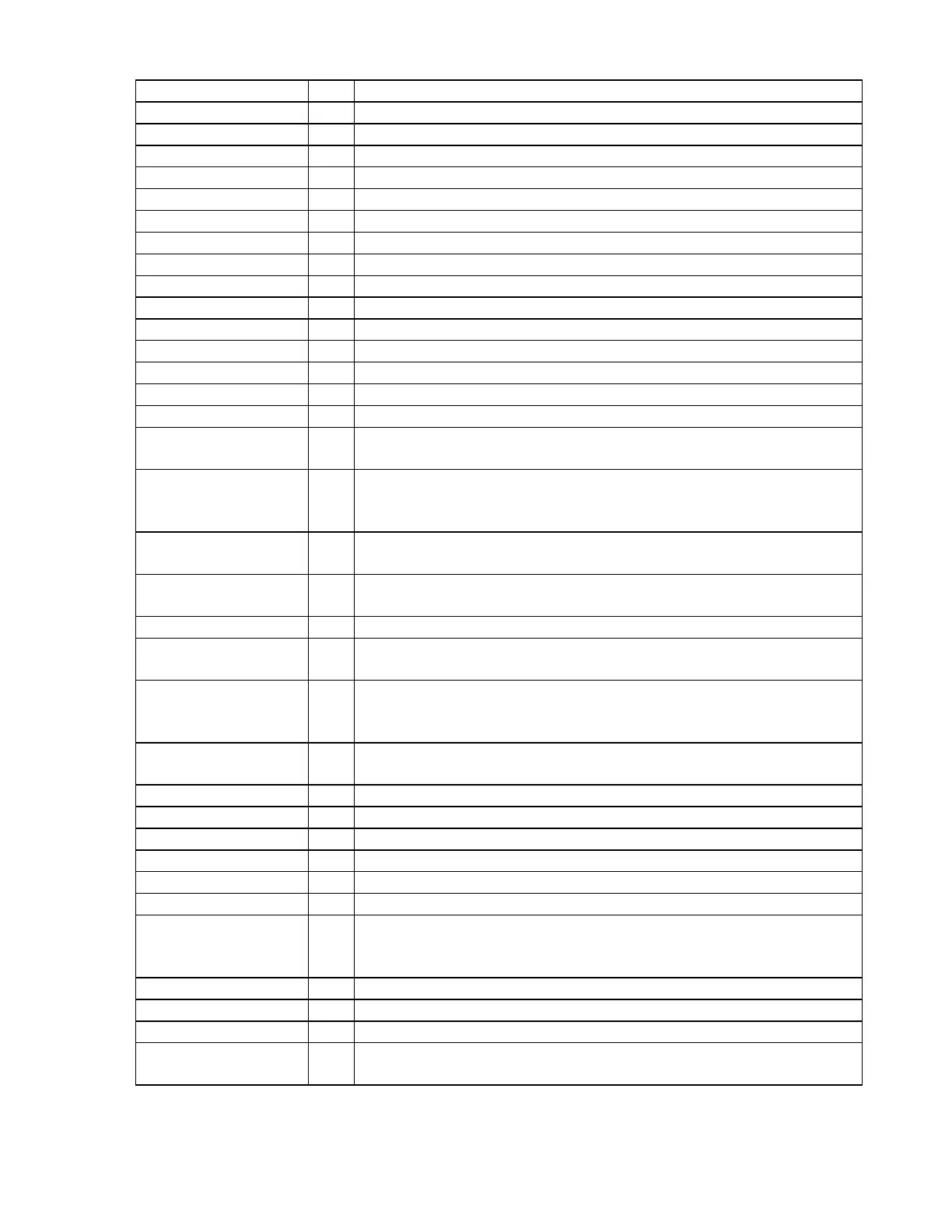

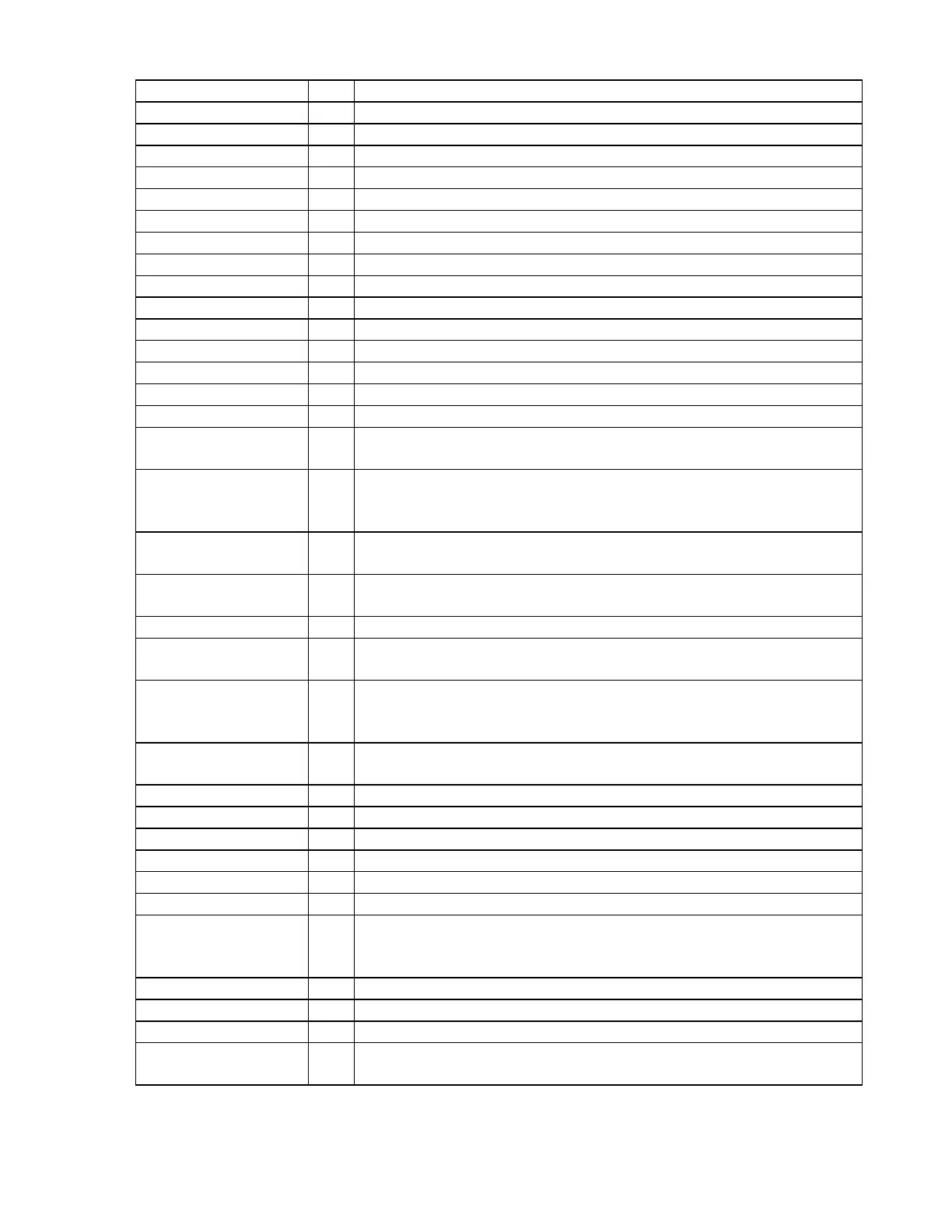

7.3.1 Traction and Pump adjustment descriptions

Adjustment Description (T=Affects traction, P=Affects Pump)

Current Limit T+P Maximum allowable motor current.

Acceleration Delay T+P Time taken to ramp up from 0 to 100% on.

Deceleration delay T+P Time taken to ramp down from 100% to 0% on.

Creep Speed T+P Minimum applied % on when drive first selected. Only PS1 on pump

Maximum Speed T Maximum allowable % on.

Cutback Speeds 1&2 T Maximum allowable % on when cutback switches active.

Accel. Delay 1&2 T Independently adjustable acceleration delays during speed cutbacks.

Dir. Brake Current T Maximum braking current during direction switch change.

Footbrake Current T Maximum braking current in neutral when F.brake switch active.

Neut. Brake Current T Maximum braking current in neutral.

Bypass Over Current T Maximum allowable current in Bypass before contactor opens.

F.W. Pull In Current T F.Weak. contactor allowed to pull in at currents < pull in level.

F.W Drop out Current T F.Weak. contactor will drop out at currents > drop out level.

Power Steer Delay T Delay after power steer trigger removed until contactor opens.

Seat Switch Delay T Delay after seat switch opens until pulsing is inhibited.

Regen Time T Used to minimise delays for unsuccessful regen attempts at lowspeeds.

Higher numbers give regen at lower speeds. 0 forces plugging only.

Brake Factor T Multiplication factor used to scale regen currents into end plug currents

to improve regen to plug transition. E.g. Regen direction brake current

=100A, Brake Factor=0.8, Plug current at end of braking cycle=80A

Zero Levels T+P Used to select minimum voltage input level for function. E.g. an Accel

Zero level=0.5V means traction pulsing begins at 0.5V I/P

Full Levels T+P Used to select maximum voltage input level for function, E.g. an Accel

Full Level of 4.0v means 100% pulsing is reached at 4V I/P

Speed Limit T Used with external speed sensor to provide speed limit feature.

D.Motor Inner Angle T Sets start of inner motor cut band. Typically 45° for non-proportional

systems and 10 ° for proportional systems.

D.Motor Outer Angle T Sets start of inner motor reverse band. Typically 75° for non-proportional

systems and ( 90 - tan

-1

( track / ( 2.wheelbase ) ) ) °

for proportional systems.

D.Motor Inner Ramp T Time taken to ramp up pulsing after inner motor drop out on any Dual

Motor Non Proportional system

D.Motor Outer Ramp T As above, except ramp up time after inner motor reversal.

Inch Speed T Maximum allowable % on during inching operation.

Burst Inch Delay T Timer to allow inching for a set period only.

Bypass delay T Time for Bypass contactor to close after 100% on reached

Pump speeds 1-7 P Maximum allowable % on’s when respective switch active

Power Steer Speed P As above, but for Power Steer speed.

Pump Comp. 1-4 P Set-up compensation by adjusting the relevant pump speed to give the

required minimum no load speed, then set the associated compensation

adjustment to give the same speed under full load conditions

Power Steer Comp. P As above but for Power Steer speed compensation.

Power Steer Ramp up P Independent acceleration delay for power steer function.

P. Steer Ramp down P As above but deceleration delay.

Speed 5-7

Priority/Additive

P Lower numbers have priority over higher numbers. Additive is where

the speeds 5-7 are added to lower numbered switches.

Loading...

Loading...