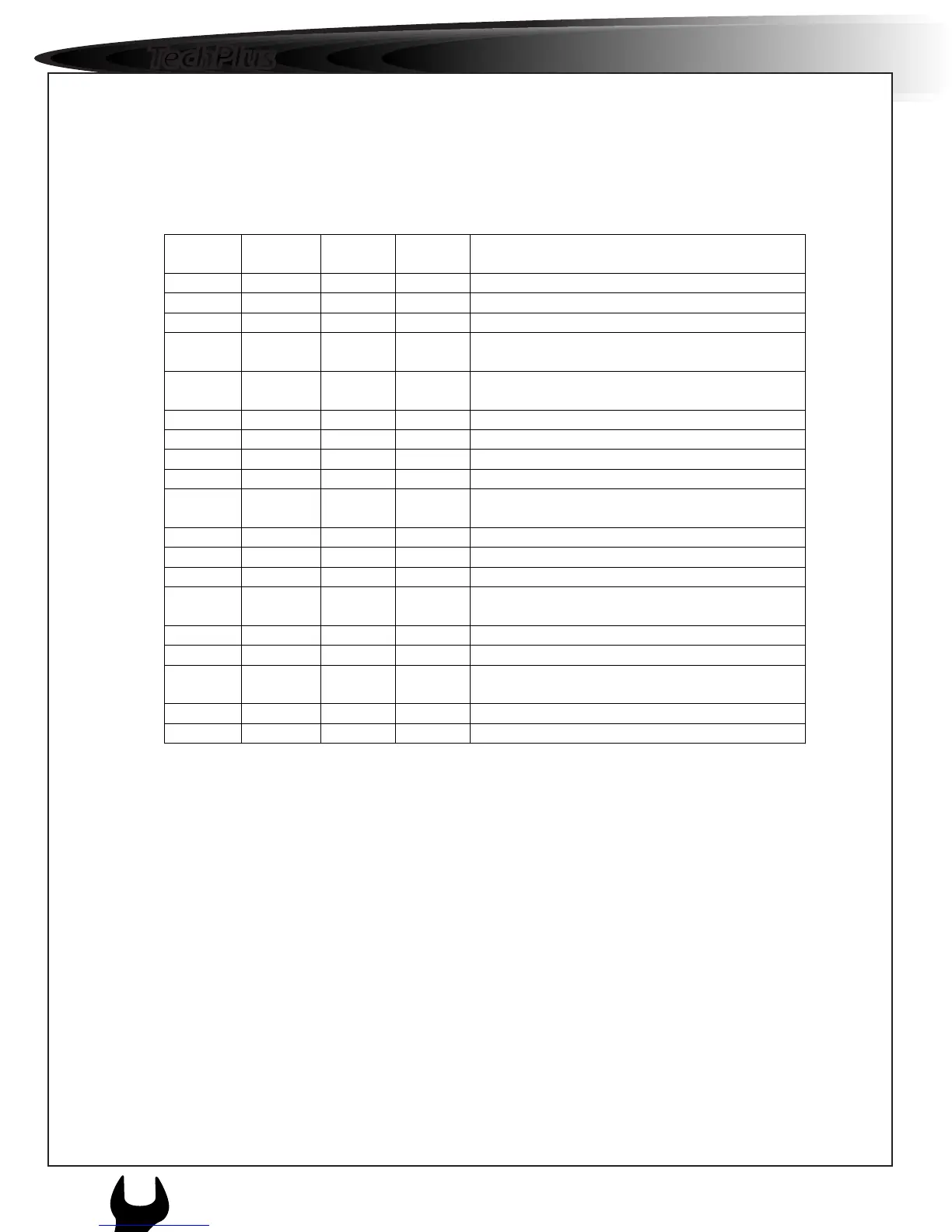

Maintenance Inspection Schedule

Weekly Monthly Semi

Annual

Annual Inspect/Service These Items

Electrical

• •

Check Compressor clutch operation

• •

Inspect D.C. fan motors

• •

Inspect wiring harness for damaged wires

or connectors

•

Clean and re lubricate power studs at

condenser

Refrigeration

• • •

Check refrigerant level

• •

Replace receiver drier

•

Check refrigeration lines for signs of

rubbing, damage, and oil leaks

•

Perform acid test on compressor oil

Structural

• • • •

Visually inspect unit for loose or broken

parts

• • • •

Clean defrost drains

• • • •

Inspect belts for proper tension

• • •

Clean entire condenser and evaporator

coils

• • •

Check all mounting bolts

Note: Use only PAG (Poly Alkylene Glycol) compressor oil in R-134a systems

Do not mix PAG compressor oil with other synthetic oils

Keep PAG oil in tightly sealed containers. If oil becomes contaminated with

moisture (colour will change to milky) or standard oils, dispose of properly – Do

Not Use

Note: When servicing a R-134a system, use only those service tools certified for

and dedicated to R-134a refrigerant and PAG compressor oils

` Residual or non HFC refrigerants or oils will contaminate the R-134a

System

Note: Recover all refrigerant and re cycle or dispose of properly

Loading...

Loading...