English

10

BLAST CHILLER ISTRUCTION

6 GREAT TECHNOLOGY AND PROCESS VALUE

• Putting freshly cooked food directly in the storage unit is a

mistake! Cooling is static and not very powerful, the chilling

time is too long and bacteria develop rapidly in large quan-

tities.

• Only by using a chilling system with forced ventilation heat

exchange can we be sure that we are preserving the high

initial quality of the food: its appearance, colour, flavour and

aroma.

• Cold, like heat, if not properly managed and metered can vi-

sibly damage food.

• Since every food has its own characteristics, the use of a spe-

cific chilling system every time is important.

Our equipment is characterized by its versatility and the avai-

lability of several functions in the same machine.

- Quick “Soft” blast chilling for delicate products with a redu-

ced thickness.

- Quick “Hard” blast chilling for all dense products, in large

pieces or packaged.

- Quick freezing.

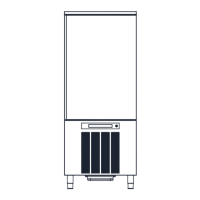

6.1 "SOFT" BLAST CHILLING

From +70°C to 3°C at the product core within a maximum of

90 minutes, with air temperature that is always and only po

sitive 0/+2°c, avoiding any type of freezing of the surface

of the food.

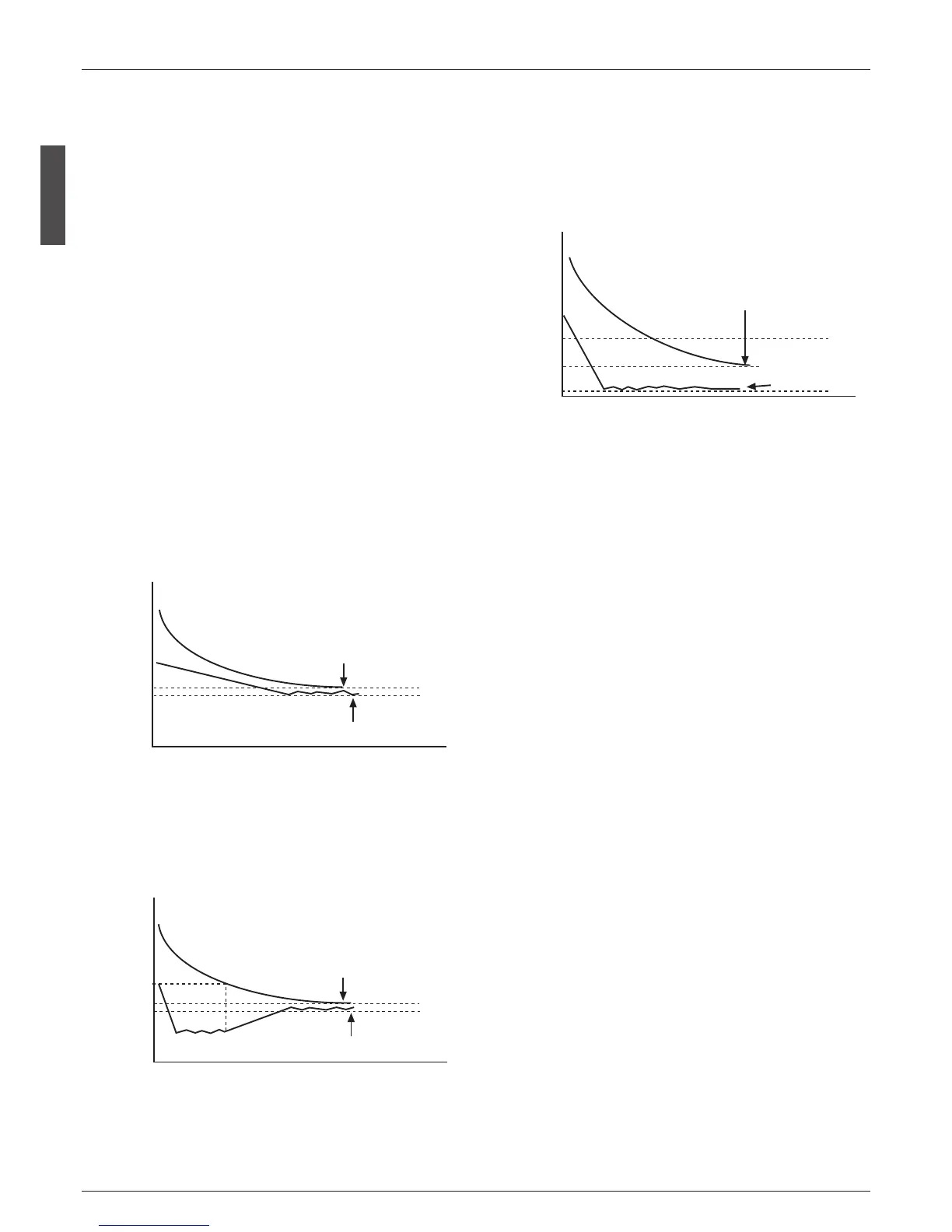

6.2 "HARD" BLAST CHILLING

From +70°C to +3°C at the product core within a maximum

of 90 minutes, with variable chamber air temperature auto

matically controlled by the computer. This system allows for

a 2530% time savings in comparison to the "soft" cycle!

6.3 QUICK BLAST FREEZING

function available only in certain models

From +70°c to 18°c at the product core as quickly as possibly

and within at most 4 hours, with a chamber air temperature

of 40°c. Rapid cold penetration prevents the transformation

of water into macrocrystals, thus not ruining the consistency

and integrity of the food.

Each cycle can be manually controlled using the timer or au

tomatically controlled with the food probe. The automatic

storage function at the end of the cycle and the automatic

and manual defrosting cycles complete the exceptional

blast chiller accessories.

Temp.

+70°C

+60°C

+50°C

+40°C

+30°C

+20°C

+10°C

+3°C

0+2°C

-10°C

-20°C

-30°C

-40°C

10 20 30 40 50 60 70 80 90 Tempo

temperature

at the

product core

Processing air

temperature

Temp.

+70°C

+60°C

+50°C

+40°C

+30°C

+20°C

+10°C

+3°C

0+2°C

-10°C

-20°C

-30°C

-40°C

10 20 30 40 50 60 70 80 90 Tempo

temperature

at the

product core

Processing air

temperature

Temp.

+70°C

+60°C

+50°C

+40°C

+30°C

+20°C

+10°C

+3°C

0+2°C

-10°C

-20°C

-30°C

-40°C

0, 30’ 1 2 3 4 ore Tempo

temperature

at the

product core

Processing air

temperature

Loading...

Loading...