Betriebsanleitung/Operating manual

F5301/F53C1/F53S1

www.tecsis.de BD_BE_907 c 31

6.2 General installation guidelines

• The loads operating upon the load pin must be introduced perpendic-

ular in the load direction.

• Torsion and shear forces need to be avoided. Components of angular

applied measured variables are also a part of transverse loads and

lateral forces.

• Torsional moments, transverse or centric loads and side forces cause

measurement errors and can damage the load pin permantly.

• The axle bracket grooves also serve as a reference for aligning and

fix the load pin against rotation.

• The DIN 15058 axle bracket must be attached in such a way that the

measuring axle is prevented from twisting in the bearing and does not

have any axial play. The axle bracket and the attaching must not be

loaded by example the axle load. The Axle bracket must be

secured with undetachable fixing.

• The measuring axle may only be subjected to load if the correct type

of bearing has been used. Loads occurring in other equipment may

change the zero signal and result in permanent damage.

• The introduction of force in the centre must not wander and must be

installed in such a way that axial shifts are prevented. However, force

by-passing may not occur.

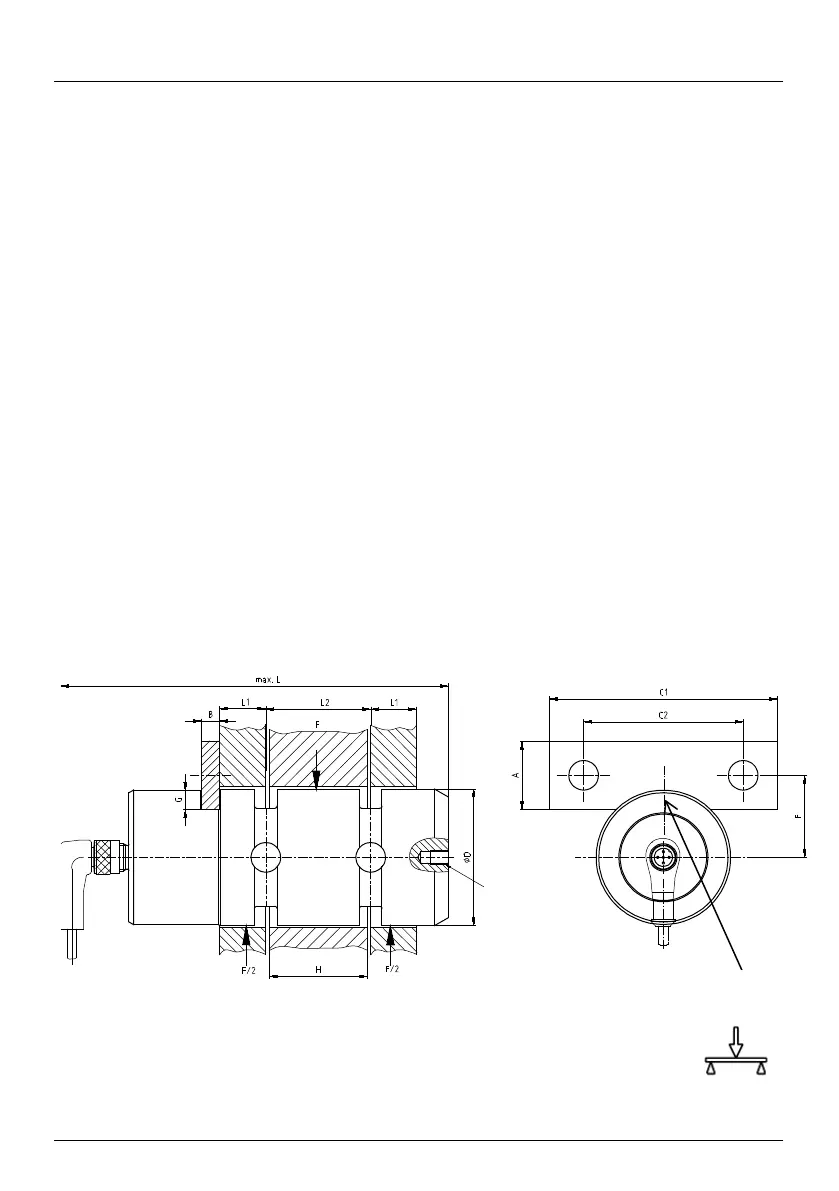

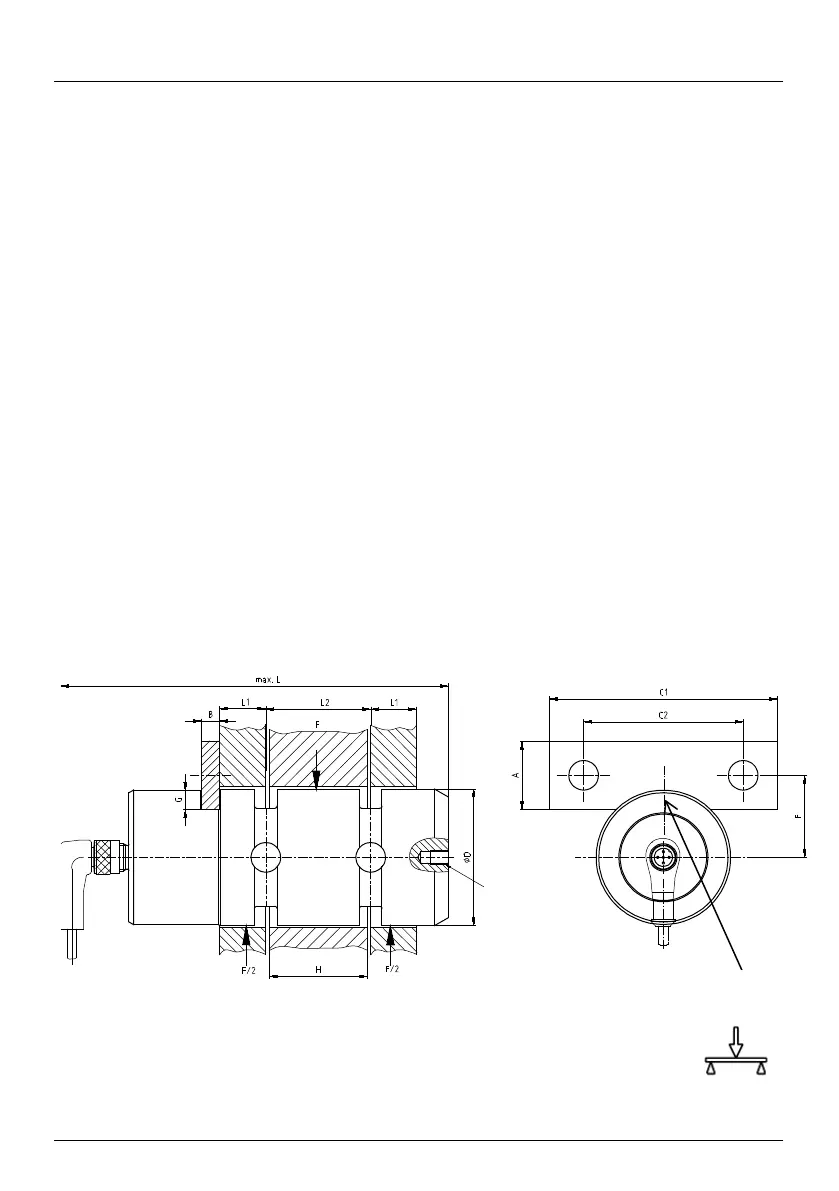

Fig. 4 Installation situation of a load pin

Axle bracket acc. to DIN 15058

nection

(M6 8/12

deep)

„force direction“

Loading...

Loading...