operation.

2.6.1

Using new

inset

½” metal seal

Hand-tighte

damaged

possibili

2.6.2

connect inlet

2.6.3

pressurised

Fig

peratures are generated during normal operation.

-

work as this can get hot during n

Risk. Very low temperatures generated during

. Avoid contact with exposed pipe

-work.

ilver plated “O” seal (supplied in ac

refrigerant line co

fitting. The “Coil In” (CI) is a ½” metal seal

coil) and the “Coil Out”

female fitting (f

rom the Meissner coil to the unit)

n the nuts to ensure that the

the installation process.

ings are fully tightened. Installation engineers mu

-

90nn) on the couplings to minimiz

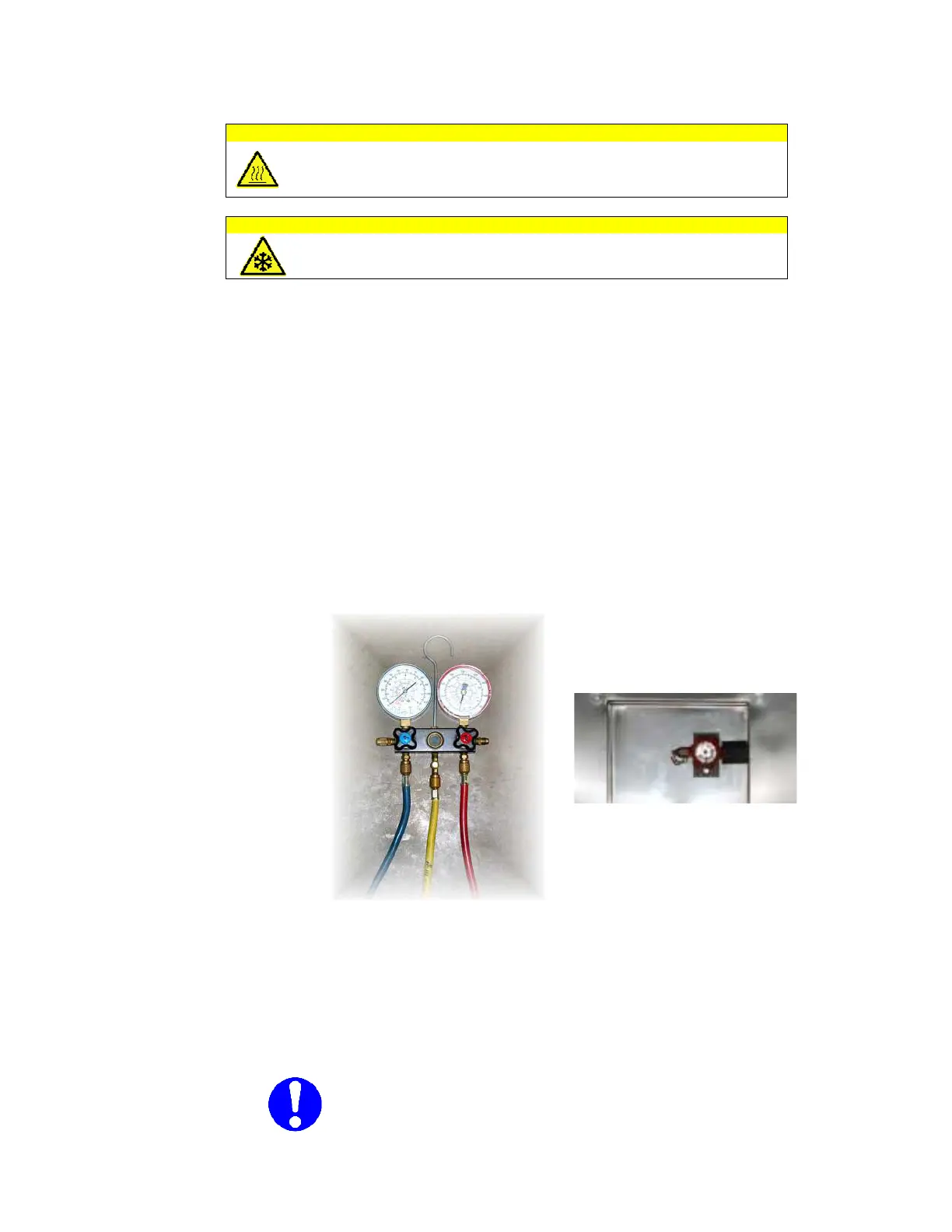

of Refrigerant Manifold gauges as shown below (

(centre (yellow hose) to a

high pressure

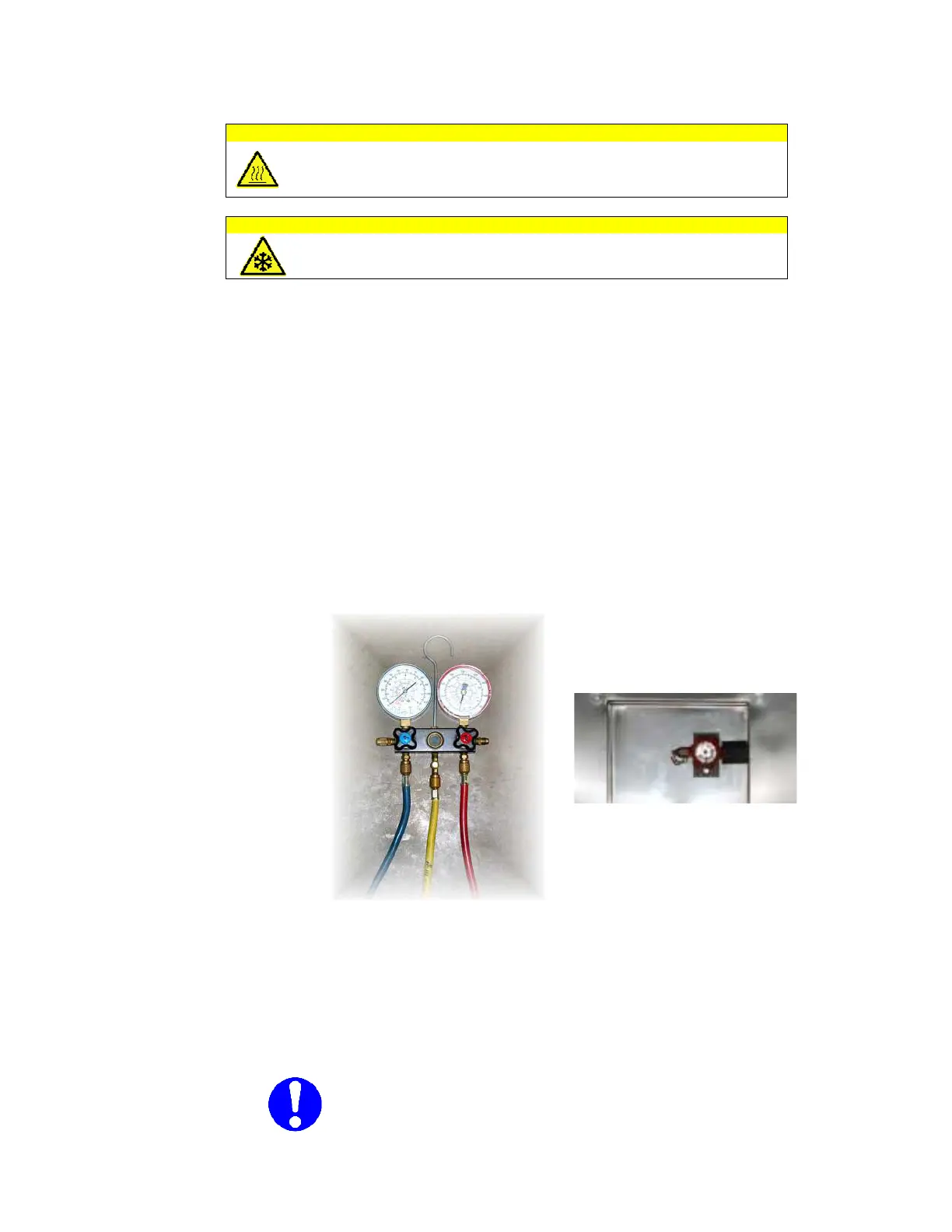

valve (see fig 7).

see fig 7)

3.78Bar (1.78Mpa)). Using a su

apy water) check the connectio

hiller ends for signs of leakage. T

at leas

t 15 minutes while inspection is checke

Note:

When pressurising the lines,

DO NOT

the balance pressure of the unit.

Refrigerant Manifold

fig 8)

manifold

exceed

Loading...

Loading...