Telemark Cryogenics Microprocessor Based Cryochillers

Page

51

of

63

Revision 1.0.7 October 2018

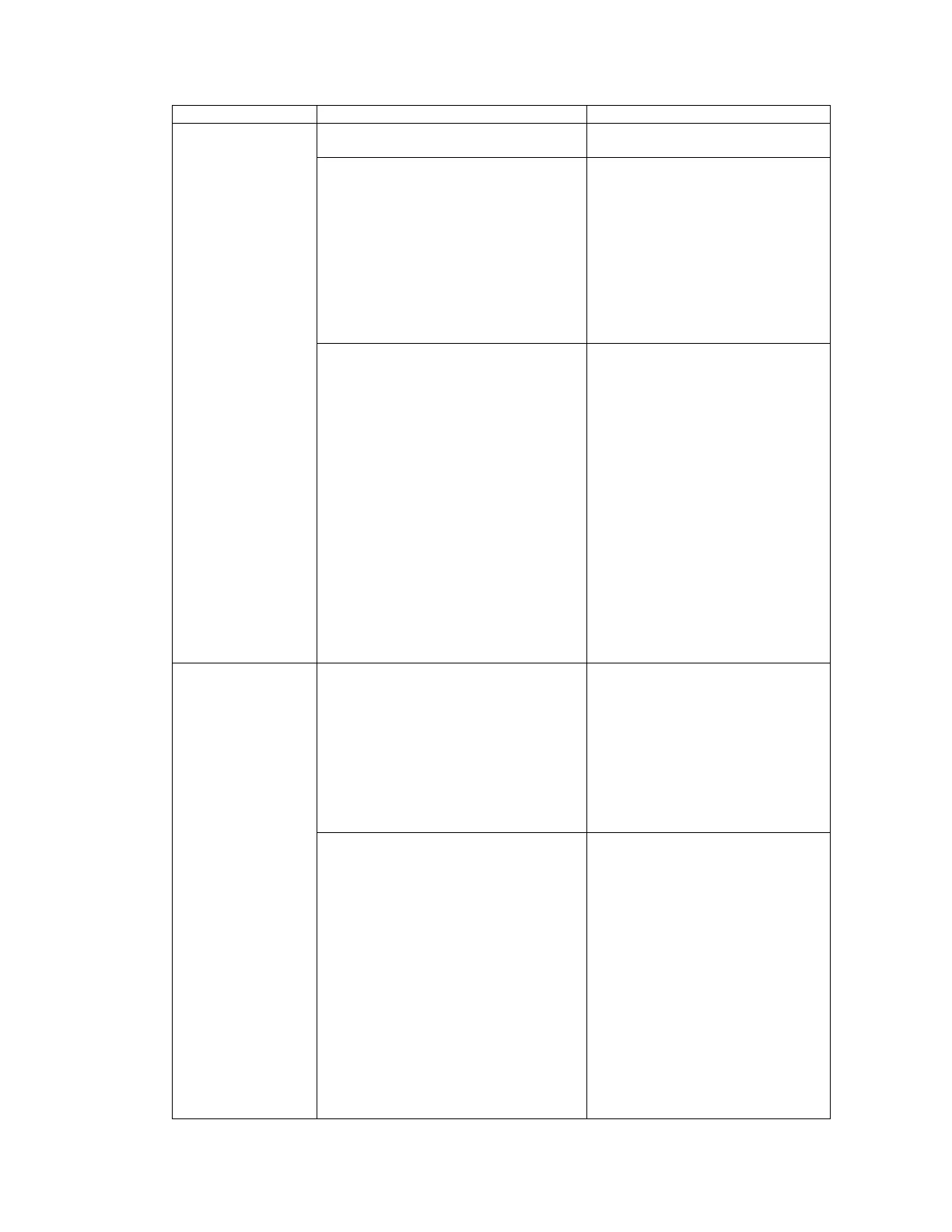

System does not

cool CT fails to get

colder than -140 to

-150

o

c after 45

minutes in standby

Error Code “E3”

Error Code “E2”

Water temperature too high or too low

Correct water temperature and

flow rate reset system

System has a leak

System should be shut down for a

period of approximately 48 hours

(or until the value of CT is greater

than 10°c. The values of DP and

SP should be taken and compared

with the values following

installation. Locate and repair leak

pay attention to all flare and

refrigeration line joints before

topping system up to

recommended pressures.

If SP is above 45 psi start valve may

have become stuck open. Typically

CT will also not be lower than

-100

o

c

With valve cover removed and the

system powered, check the start

valve solenoid becomes

magnetised (use screwdriver). If

solenoid magnetised switch unit off

and restart after 30 minutes. If coil

is not magnetised switch unit off.

Remove valve solenoid and heat

valve gently to 100°c with hot air

gun. Cryochiller systems have a

patented refrigeration system,

which prevents valve problems

under normal operation. Almost all

solenoid valve problems are traced

to poor installation introducing

moisture into the vacuum system.

If this does not correct fault stop

unit allow to warm up for 48 hours

and restart.

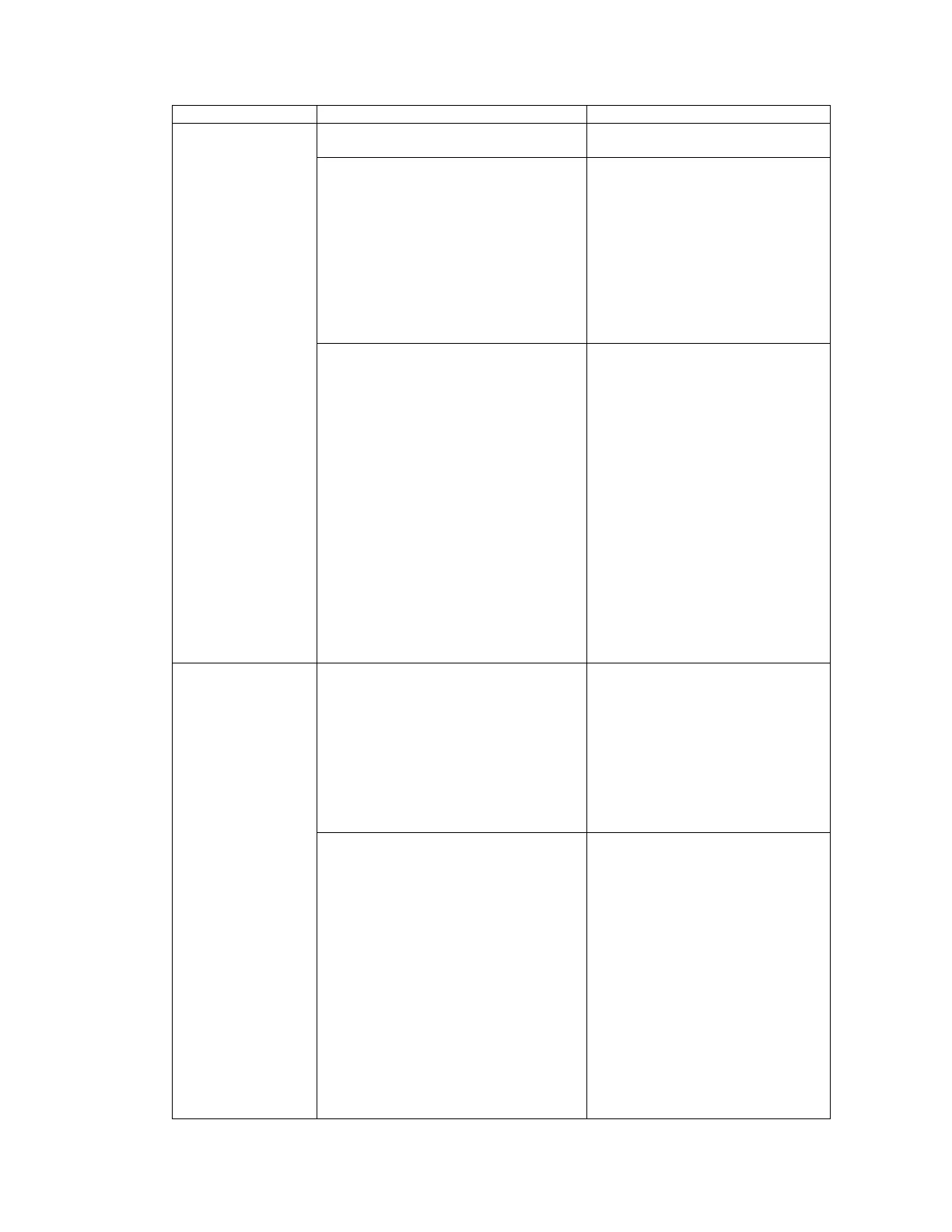

Unit does not cool

when in “COOL”

mode. CI and

CO temperatures

do not drop

Cool valve hand valve is closed or

common return (suction hand valve) is

closed

Switch off allow valves to return to

ambient temperature before

attempting to open. Operating

valves while cold can cause

damage. Occasionally common

return (suction hand valve may

become stuck down in this case

the cryo-coil should be isolated

and the procedure for installation

should be repeated

Cool solenoid valve not functioning

With valve cover removed and the

system check the cool valve

solenoid becomes magnetised

(use screwdriver). If solenoid is

operational run system in standby

remove valve solenoid and heat

valve gently to 100°c with hot air

gun. Replace solenoid and

attempt cooling – Cryochiller

systems have a patented

refrigeration system, which

prevents valve problems under

normal operation. Almost all

solenoid valve problems are traced

to poor installation .

Loading...

Loading...