- 15 -

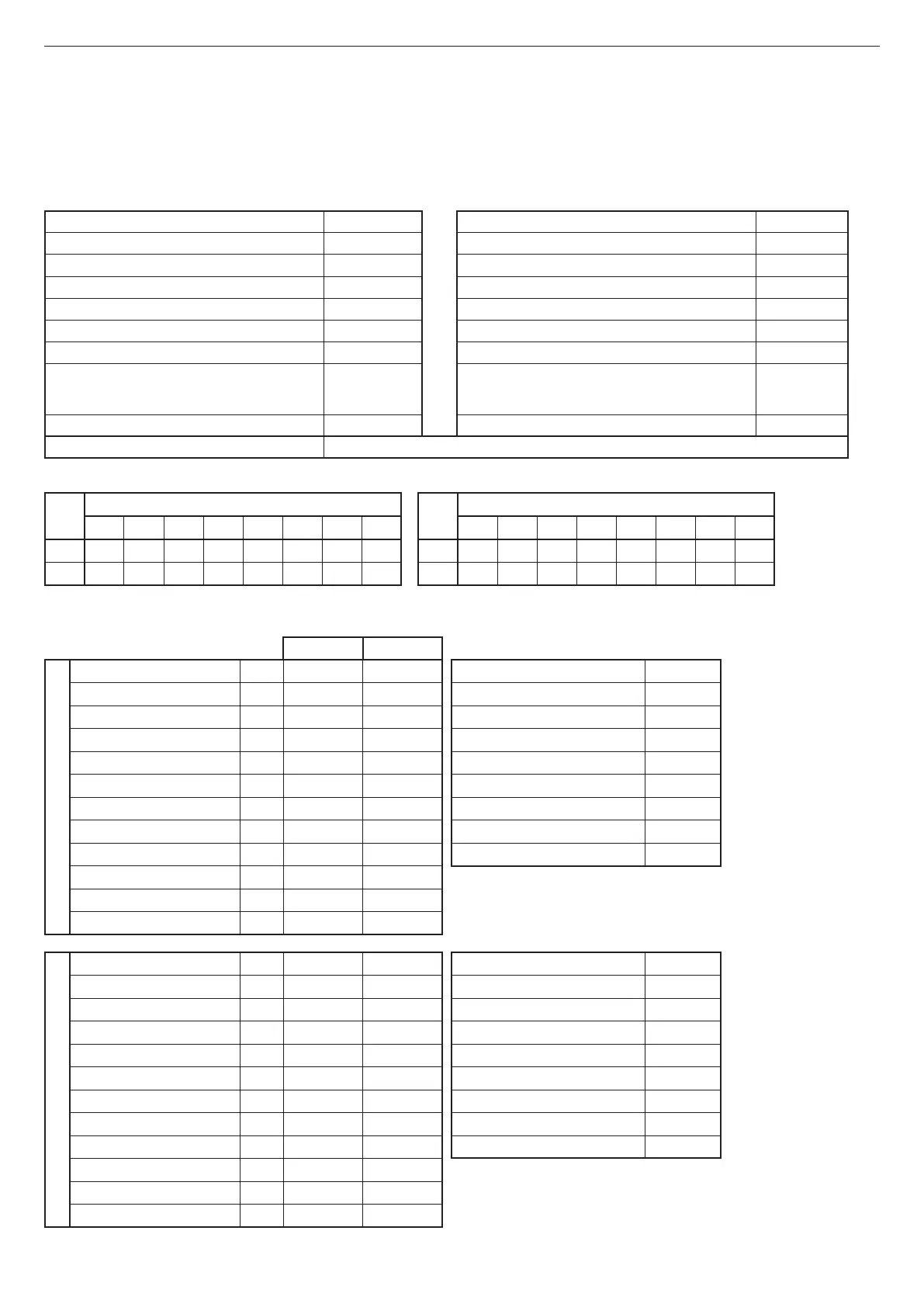

INSTALLERTOCOMPLETE

COMMISSIONING CHECK LIST

Site Name/address: ..........................................................................................................................................................................

Installing Company ...................................................................................................... Date: ..........................................................

Serviceman: ............................................................................................................... Tel: ............................................................

Model ..................................................................... Serial No..................................... Site Ref. ....................................................

Unit mounted level? Y / N Supply voltage checked? Y / N

Temperzone recommended drain trap tted? Y / N External electrical isolator tted? Y / N

Water drains tested okay? (panels on, fan running)

Y / N Indoor Plug fan set voltage or l/s V l/s

Does unit have adequate safe access? Y / N Are temperature controller’s parameters set? Y / N

All electrical terminals are tight? Y / N Checked for excessive noise & vibration of unit? Y / N

Return air lters tted? Y / N Has client had controls demo? Y / N

Removed compressor shipping wedges? Y / N Electrical Certicate Of Compliance issued? Y / N

Refrigeration leak checked? Y / N If installed indoors, is there adequate ventilation to

disperse any refrigerant in the unlikely event of a

leak.

Y / N

Is air ow set and balanced? Y / N

Thermostat type: BMS / SAT-3 / TZT-100 / Other? (name):

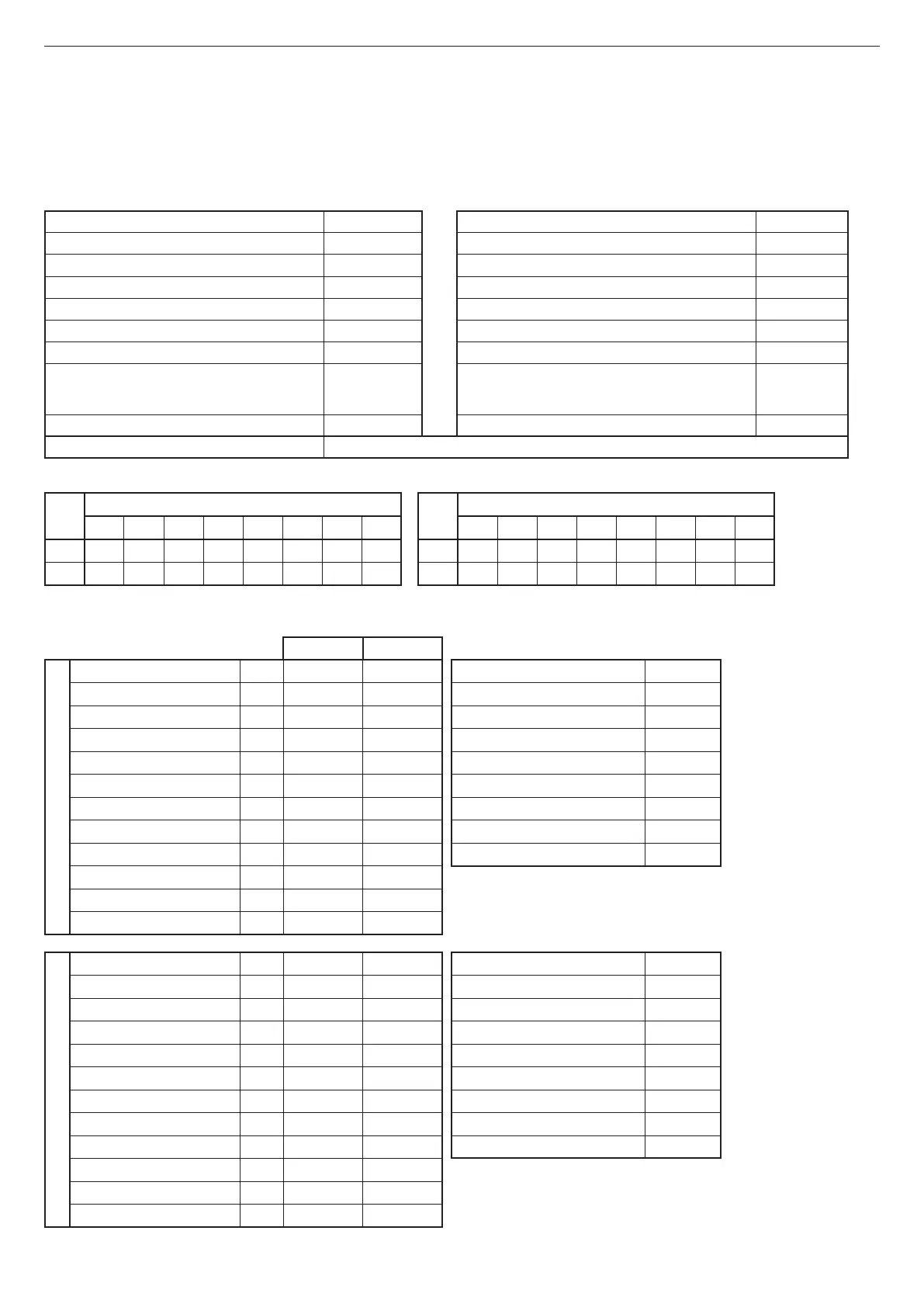

Mark UC8 dip switch positions with an 'X'

SW1 SW2

1 2 3 4 5 6 7 8

9 (1) 10 (2) 11 (3) 12 (4) 13 (5) 14 (6) 15 (7) 16 (8)

On On

Off Off

Record the following UC8 monitored conditions using push button SW3 (repeat to scroll through list).

IMPORTANT: Digital compressors must be operating at 100% for at least 10 minutes when taking these readings.

System 1 System 2

Low Pressure: SLP kPa kPa Outdoor Ambient temperature: °C

Evap temperature: Et °C °C Indoor Return air temperature: °C

Suction Line temperature: SLt °C °C Indoor Supply air temperature: °C

Suction Superheat: SSH K K Indoor fan amps : A

Discharge Line Pressure: dLP kPa kPa Fresh Air introduced : %

Condensing temperature: Ct °C °C Compressor 1 amps : A

Discharge Line temperature: dLt °C °C Compressor 2 amps : A

Discharge Superheat: dSH K K Compressor 3 amps : A

De-ice Sensor temperature: ICEt °C °C Compressor 4 amps : A

Required Capacity: CAP % %

Expansion Valve 1: EE1 % %

Expansion Valve 2: EE2 % %

Low Pressure: SLP kPa kPa Outdoor Ambient temperature: °C

Evaporating temperature: Et °C °C Indoor Return air temperature: °C

Suction Line temperature: SLt °C °C Indoor Supply air temperature: °C

Suction Superheat: SSH K K Indoor fan amps : A

Discharge Line Pressure: dLP kPa kPa Fresh Air introduced : %

Condensing temperature: Ct °C °C Compressor 1 amps : A

Discharge Line temperature: dLt °C °C Compressor 2 amps : A

Discharge Superheat: dSH K K Compressor 3 amps : A

De-ice Sensor temperature: ICEt °C °C Compressor 4 amps : A

Required Capacity: CAP % %

Expansion Valve 1: EE1 % %

Expansion Valve 2: EE2 % %

NOTE: This document to be kept with the unit. Failure to provide this completed page on request by Temperzone

may affect unit warranty.

COOLING CYCLEHEATING CYCLE

Loading...

Loading...