- 2 -

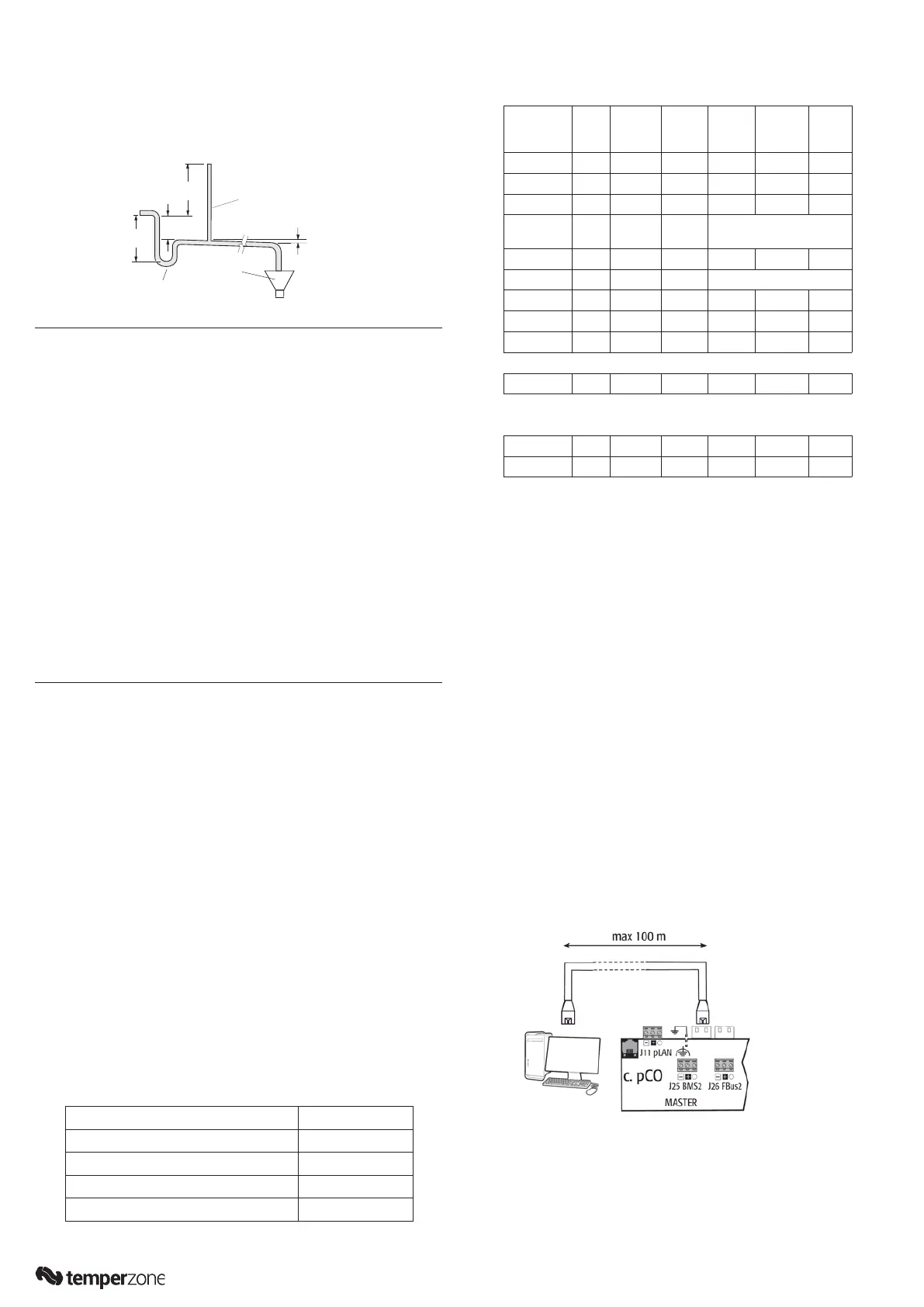

2.3 Condensate Drains

The condensate drains should be ‘U’ trapped outside the

unit. The traps should have a vertical height of at least 100

mm. The drain lines should have a slope of at least 1 in 50

and must not be piped to a level above the unit drain pipe.3.

Refrigeration System

3. REFRIGERATION SYSTEM

3.1 General

Each OPA 970 have two independent refrigeration systems

and two inverter compressors to provide the exibility

and economy of two stage operation, i.e. utilising one to

two systems as conditions vary, plus the advantage of

staggered starting, all stages being variable for improved

control and system efciency.

Each refrigeration system has been charged with R32

refrigerant; refer Specications document for amount.

3.2 Compressors

The compressors are inverter scroll type. The compressor

lubricant is POE-46 (NXG5020 or equivalent). Note, this oil

absorbs moisture quickly if exposed to open air.

Some models are a mix of single inverter and three xed

speed compressors. Please check the Specication Sheet

relevant to your unit.

4. WIRING

4.1 Electrical Requirements

Electrical work must be done by a qualied electrician

and

meet standard AS/NZS 3000.

DANGER! LIVE ELECTRICAL CONNECTIONS. ISOLATE MAINS POWER

BEFORE WORKING ON UNIT. ONLY QUALIFIED PERSONS WHO

ARE COMPETENTLY TRAINED SHOULD PERFORM SERVICE AND

MAINTENANCE TASKS.

The unit must be wired directly from a distribution board

using an appropriately sized circuit breaker. The termination

point for the mains cable is in the electrical compartment. An

isolating switch is required, near but not on the unit.

A hole for power cable entry is provided bottom right-hand

corner, next to the compressor access door. From there

route the cable into the electrical box via the hole on the

bottom of the electrical box or through the hole on the RH

side of the electrical box.

4.2 Controls Wiring

A hole for communication cable entry is provided bottom

left-hand corner, next to the compressor access door. Before

wiring, the method of control should be established from

the following list. Follow specic instructions in the following

sections. Section 4.3 is important to all sections.

Control method Section

Sensors and Inputs 4.3

BMS – BACnet Interface 4.4

BMS – Modbus Interface 4.5

Standalone 4.5

4.3 Sensors & Inputs

See table below for sensors and inputs required for each

control method.

Carel c.pCO

connections

Factory

Fitted

BMS

Bacnet/

Modbus

BMS -Low

Level

Controller

Stand

alone

Sensor Pin Signal

Room Temp. U1 0-10VDC Note 1 Note 3 × √

Room RH% U2 0-10VDC Note 1 Note 3 × √

ID Fan Speed

Req

U3 0-10VDC × Note 2

RA Temp. U4 0-10VDC √ √ √ √

RA RH% U5 0-5VDC √ Note 4

SA Temp. U6 NTC √ √ √ √

SA RH% U7 0-5VDC √ √ √ √

CO2 UC8 0-10VDC Note 1 Note 1 0 √

The following inputs relate only when using external low level control:

Enable ID4 24VAC × × √ ×

Occupancy ID6 24VAC × × √ ×

Fault NO7 Relay × × √ ×

Notes:

1. Factorysuppliedloose,tasrequiredincontrolledspace.

2.Optionallyprovide0-10VDCcontrolofindoorfanspeed,

willbeoverriddenifwrittentoBACnetorModbusindoorfan

speedregister.CanalsobesetusingaCarelpGD.

3.RoomtemperatureandRH%canbewrittenviaBACnetor

Modbusandwilltakepriorityoversensorreading,inthis

casesensorsarenotrequiredtobetted.

4.RAsensorsonlyrequiredforEconomiseroption.IfRAto

beusedtocontrolthespacethenwireRAsensorsintothe

RoomtemperatureandRoomRH%inputs.

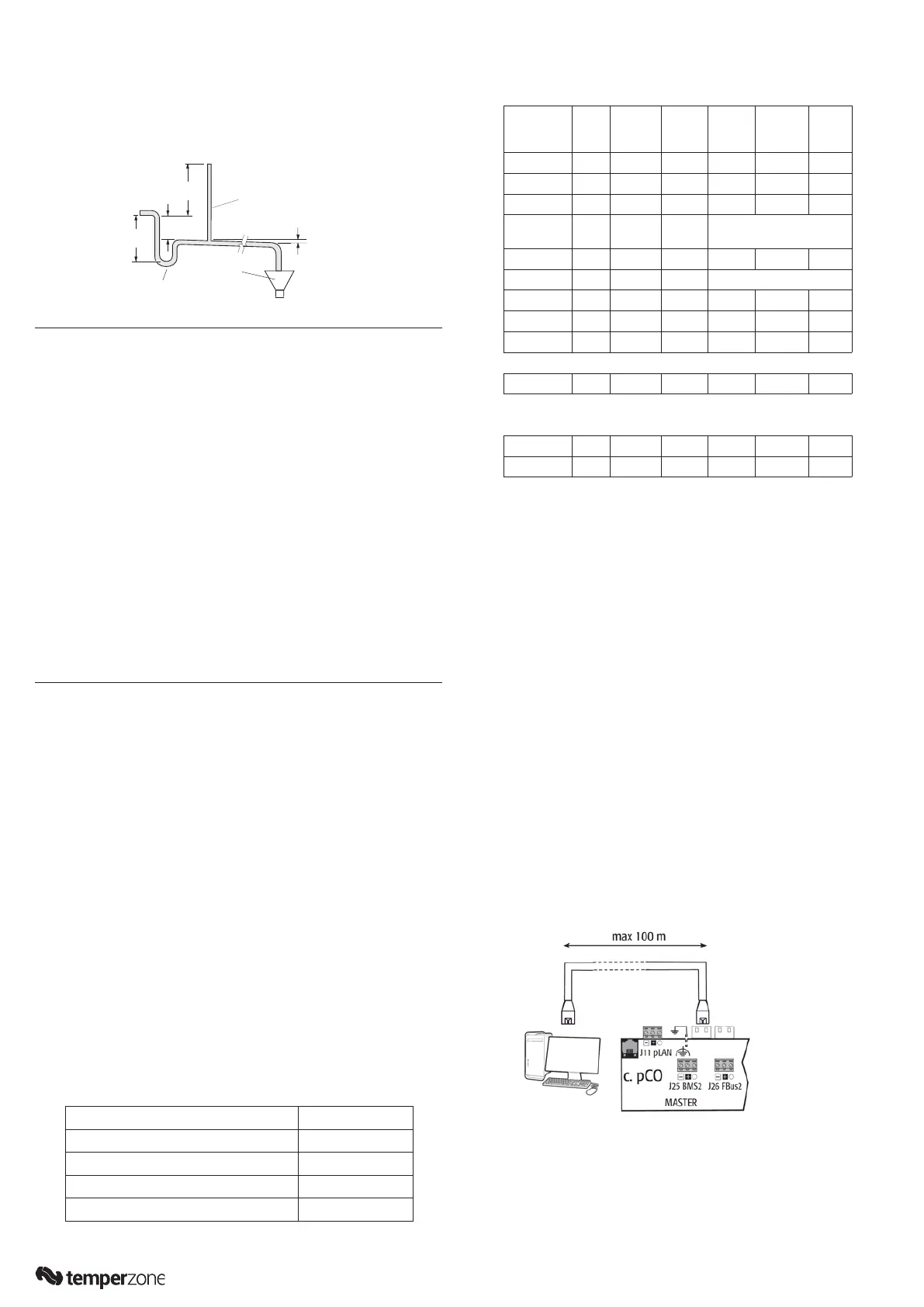

4.4 BMS – BACnet Interface

1. Install ethernet cat 5 STP shielded cable between the

port shown in the below diagram of the Carel c.pCO

controller and the network switch of the BMS. The

default IP address of the controller is 192.168.1.10; refer

Controls Setup (p.9) for details on how to change.

2. Temperature and humidity sensors can be connected

directly to the Carel c.pCO controller (see specication

sheet for wiring diagram). Alternately the space

temperature and humidity can be written by the BMS to

BACnet objects which will take priority over any sensors

that are connected.

SingleunittoBMS:

OPEN

DRAIN

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

100 mm

MINIMUM

200 mm

APPROX.

'U' TRAP

100 mm

APPROX.

VENT PIPE

FOR LONG

CONDENSATE

DRAIN RUNS

Loading...

Loading...